The Complete Knife Guide

Are you tired of struggling with dull, ineffective knives in the kitchen? The answer to all your cutting challenges lies in the power of steel.

Are you tired of struggling with dull, ineffective knives in the kitchen? The answer to all your cutting challenges lies in the power of steel.

Discover the hidden power of T10 steel with our comprehensive guide. In this article, we delve into the secrets of T10 steel and provide you

Welcome to the exciting world of knife sharpening! Whether you’re a professional chef or a home cook, maintaining the sharpness of your blades is essential

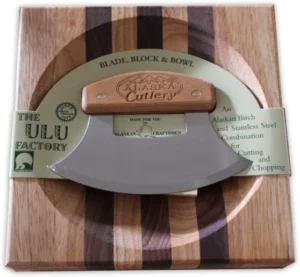

Unleash the hidden charm and adaptability of the Ulu knife with our comprehensive guide catered to culinary enthusiasts like you. With its unique design and

Bohler M398 steel has about 0.8% more carbon elements in its alloy and about 3.2% more Vanadium elements. The addition of these two increases the

The Kukri Blade: Unveiling the Secret of Its Incredible Shape Step into the world of blades as we uncover the mystery behind the iconic Kukri