3cr13 Steel: A Must-Have in Your Tool Collection

When it comes to finding the perfect addition to your tool collection, strength and durability are of utmost importance. That’s why 3cr13 steel should be at the top of your list. This high-quality stainless steel boasts incredible resilience and long-lasting performance that will exceed your expectations.

3cr13 steel is known for its exceptional strength and toughness, making it an ideal choice for a variety of tools and applications. Whether you’re a professional tradesperson or a DIY enthusiast, having tools made from 3cr13 steel ensures that they can handle the toughest tasks without succumbing to wear and tear.

Not only does 3cr13 steel stand up to heavy use, but it also resists corrosion, ensuring that your tools maintain their functionality and appearance over time. Its high carbon content provides excellent edge retention, allowing you to tackle even the most demanding cutting or scraping jobs effortlessly.

Investing in tools made from 3cr13 steel is a smart choice that guarantees reliability and longevity. So, if you want to step up your tool game, look no further than 3cr13 steel. Experience the power of durability and choose the steel that professionals trust.

What is 3cr13 steel

3Cr13 steel is martensitic stainless steel made in China. It is also referred to as 30Cr13 stainless steel. 3Cr13 stainless steel is a low carbon high chromium steel that provides good corrosion resistance but poor edge retention.

Since this steel is manufactured in China, it comes at a low price and is a perfect choice if you are looking for a quality low-end stainless steel knife.

Most people associate products made in China with poor quality, but this is not the case with 3Cr13 steel. It is very popular in the knife-making industry because it offers excellent corrosion resistance and toughness.

However, it is essential to note that this is not the knife steel for you if you are looking for a high-end knife. It is only suitable for regular knives for everyday cutting jobs and kitchens.

3Cr13 steel composition

- Carbon C 0.35%: Increases edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

- Chromium Cr 14.00%: Formation of Chromium carbides. Increases the blade’s hardness, tensile strength, and corrosion resistance.

- Nickel Ni 0.60%: improves strength and toughness. It increases hardenability but not as much as some of the other alloying elements in steel. It can enhance corrosion resistance in significant amounts

- Phosphorous P 0.04%: Increases the strength and improves the machinability of steel

- Manganese Mn 1.00%: improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

- Silicon Si 1.00%: Increases strength and heat resistance.

- Sulfur S 0.03%: Improves machinability.

3Cr13 Steel Properties

3Cr13 Steel Hardness

3Cr13 has a hardness of 53-55HRC as per the Rockwell hardness scale. However, the specific hardness varies with the heat treatment used.

This steel contains low amounts of Carbon in its composition and, hence, moderate hardness. It is because of the low hardness that knives made from this are cheap.

3Cr13 Steel Toughness

As a rule of thumb, steel with low hardness offers great toughness, which is the case with 3Cr13. The high toughness of this 3Cr13 steel makes it a go-to for many knife makers.

You can trust a knife made from this steel to withstand impacts and tough applications without breaking or chipping. Read about the strength of Super Knife Steel here for an informative comparison.

3Cr13 Steel Edge Retention

3Cr13 does not stay sharp for long compared to high-end steel with high hardness levels, but it does not come last in edge retention. The edge retention you get from this steel is equivalent to its price, and it is even better than other steels in the low-end category.

Do not purchase knives made from this steel if you will be using them for outdoor activities or in situations that do not give you a break to sharpen.

3Cr13 Steel Corrosion resistance

3Cr13 steel is stainless steel because it contains high amounts of Chromium in its composition. It can be suitable for use in humid and wet environments.

However, 3Cr13 is not entirely pure stainless steel, meaning that it will rust if frequently exposed to corrosive situations.

This calls for proper care and maintenance. Do not leave 3Cr13 knives dirty or in water. Wash and dry them and possibly oil the blades to keep rust at bay.

What is 30Cr13 stainless steel?

30Cr13 stainless steel is another name for 3Cr13 stainless steel.

3Cr13 Steel Wear resistance

This steel’s excellent hardness and toughness balance results in great wear resistance. You can trust knives made from this steel to serve you for long without deforming or chipping.

Sharpening

The ease of sharpening steel is directly affected by its hardness. Since 3Cr13 steel is moderately hard, it is easy to sharpen.

This feature offsets the poor edge retention of this steel. With simple sharpening tools, even beginners can achieve a sharp edge with this steel.

Steel quality

3Cr13 steel quality can be termed as entry-level steel. It is low-carbon stainless steel with good corrosion resistance properties but low Rockwell hardness.

3Cr13 steel, also called 30Cr13, is produced in China as an imitation of AISI 420J2 but lacks Nickel in its composition.

3Cr13 steel quality is low; it provides low edge retention, moderate toughness, and good corrosion resistance.

3Cr13 steel quality falls behind its Chinese counterparts like 8Cr13MoV steel, 7Cr17Mov, and 8Cr14MoV steel.

Steel equivalent and comparison

3Cr13 vs 8Cr13MoV

Both 3Cr13 and 8Cr13MoV are Chinese-produced steel with high chromium content qualifying them as stainless steel. 8Cr13MoV steel is higher quality steel as it contains a high amount of Carbon and added vanadium in its composition.

8Cr13MoV stainless steel contains almost double the carbon amount of 3Cr13 steel. This enables it to achieve high Rockwell hardness.

The high Rockwell Hardness translates to better edge retention and wear resistance; thus, an 8Cr13MoV steel knife will provide better edge retention and be more durable than a 3Cr13 steel blade.

8Cr13MoV knife blade will also provide better corrosion resistance than a 3Cr13 knife blade. It contains additional Nickel in its alloy, which aids in corrosion resistance.

3Cr13 steel vs 1055 carbon steel

These steel grades fall under the same price tag but differ in performance. 1055 contains more Carbon than its counterpart and offers better edge retention, wear resistance, and hardness.

3Cr13 outshines 1055 in corrosion resistance. It has more chromium elements in the composition to attain the stainless-steel status.

1055 steel will be better for large knives like swords as it gives a good balance between toughness and hardness. It is also easy to work with in terms of forging and grinding.

3Cr13 stainless steel vs 420 steel

Both 3cr13 and 420 steel contain high amounts of Chromium to make them stainless steel hence great corrosion resistance. However, 3Cr13 contains more Carbon than 420 steel, making it harder and better in edge retention and wear resistance. 3Cr13 blades are a perfect choice for everyday use.

It is worth noting that the 3Cr13 composition resembles that of AISI 420J2 more than it resembles that of the original AISI 420 steel.

The only difference is that 420J2 stainless steel has added Nickel (1%), improving its properties over 3Cr13 steel.

3Cr13 steel vs D2 steel

D2 steel is tool steel designed to offer extreme wear resistance and edge retention. It contains a low amount of Chromium in its alloy and thus does not qualify as stainless steel.

You will get better corrosion resistance with a 3Cr13 knife blade than you will get with a D2 knife blade.

D2 steel beats 30Cr13 stainless steel in edge retention by a considerable margin. D2 steel edge retention is similar to most high-end knife steels out there like CPM 154, CPM MagnaCut, and the popular S35VN steel.

In terms of toughness, the low-end 3Cr13 steel will provide slightly better toughness as its Rockwell hardness is relatively low compared to D2 steel, which makes it less prone to chipping and cracking.

With low hardness and wear resistance, it will also be much easier to sharpen a 3Cr13 blade than it will be to sharpen the highly wear resistant D2 tool steel.

3Cr13 vs 440C stainless steel

AISI 440C stainless steel is better steel than 3Cr13 stainless steel. A 440C stainless steel blade will offer you excellent corrosion resistance and provide you with excellent edge retention.

AISI 440C steel edge retention comes from its composition that is high in Carbon. This enables the formation of a high volume of carbides with other elements, which is excellent for hardness and edge retention.

While 3Cr13 stainless steel edge retention is lower than budget Japanese AUS 8 steel. Grade 440C stainless steel edge retention is similar to premium Japanese VG10 steel.

3Cr13 steel blade will be tougher and easier to sharpen than a 440C steel blade due to the reduced hardness.

In terms of performance, you will get a better blade with AISI 440C steel; however, it will be more expensive than a 3Cr13 steel blade.

Is 3cr13 Stainless Steel Good for Knives?

Yes! 3Cr13 is good quality steel in the low-end steel category. It offers great corrosion resistance, toughness and it is easy to sharpen.

The properties of this steel are not as good as with premium knife steel, but these properties are decent for the price of this steel.

It offers a good option for low-end knives. Also, check 4Cr14 steel that falls on the same budget.

Is 3Cr13 steel good for swords?

For steel to be suitable for a sword, it needs to be extremely tough to avoid easy breaking, chipping, or cracking when in use. Most blade steels will be ideal for small and ordinary knives but not for swords.

3Cr13 stainless steel is fairly soft steel, and, when forged to a sword length, it will easily bend or chip as its toughness is not that sufficient.

Better steel for swords would be 80CrV2 steel, 8670 steel, 1095 steel; they have an outstanding balance of toughness and hardness.

This allows them to be drawn to considerable lengths without breaking or bending during forging or use.

Is 3Cr13 steel durable?

With a Rockwell hardness of 55-57 HRC, 3Cr13 stainless steel is not the hardest steel out there; it belongs to the low-end category. This hardness level is durable for daily tasks.

A 3Cr13 stainless steel blade will not last for long with continuous grinding. It quickly loses metal when sharpening and grinding.

What is 3Cr steel?

3Cr steel is low-budget stainless steel from china. Its chemical alloy largely resembles that of AISI 420J2 steel. 3Cr steel is low on Carbon at about 0.35% max.

The low Carbon in 3Cr stainless steel alloy significantly reduces Its Rockwell hardness level and, in turn, edge retention.

3Cr steel has a high chromium content(14% max). This qualifies it as stainless steel, giving it good corrosion resistance properties.

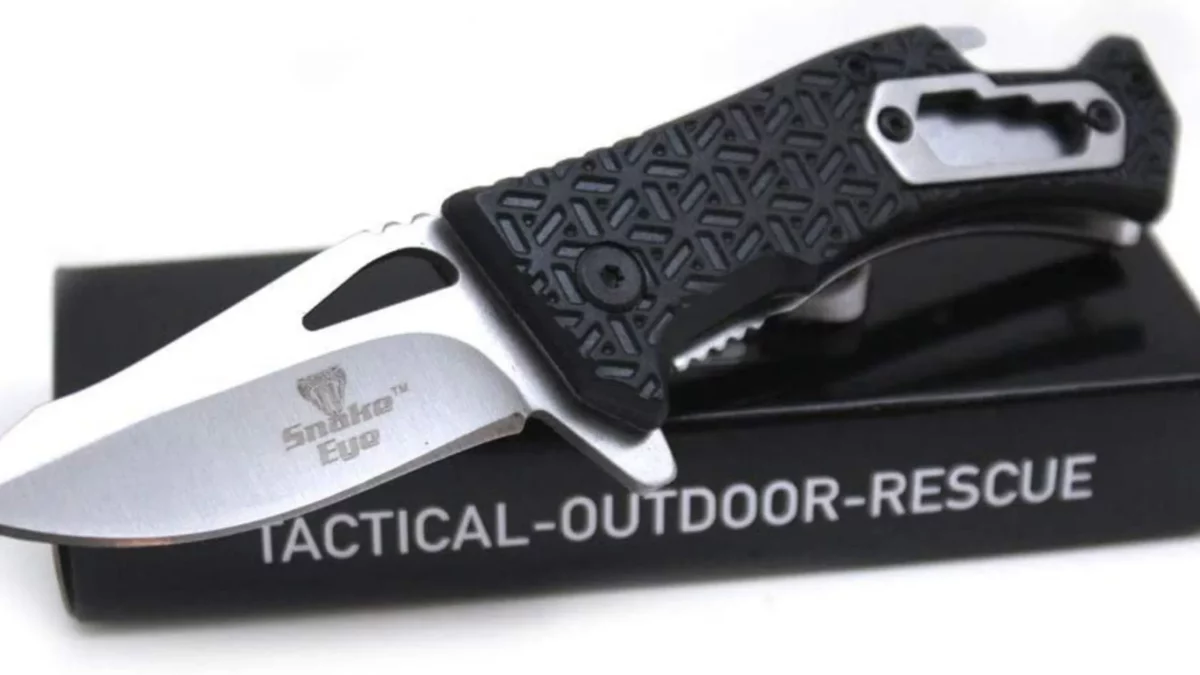

Check Out This Beautiful Snake Eye Karambit Tactical Knife