Are you interested in knives and want to learn more about the Rockwell Hardness Scale? The good news then is that you no longer need to look! That’s because we are about to give you a thorough lesson of this important tool and show you how important it is in the world of cutlery.

The strength of blades is a key factor in how well they work and how long they last. The Rockwell Hardness Scale is a clear way to measure how hard a knife is, which helps keep quality standards high across the business. If you understand this scale, you’ll be able to make smart decisions and pick the right knife for your needs. This piece will look at the complicated Rockwell Hardness Scale and explain how it works and what the different levels of hardness are.

We will break it all down to an easy-to-understand topic. At the same time, we will cover everything you need to know to become a knowledgeable knife enthusiast. Whether you are an experienced cook or a passionate collector. Get ready to find out the secrets behind great performance and long-lasting qualities of your favorite blades?

If you are keen on knife specifications, you must have seen a number with RC or HRC after or before it, for example, 54 HRC or RC60. The numbers represent the Rockwell rating, a scale used to determine the hardness of a material.

HRC or RC is the abbreviation for Rockwell Hardness Scale. So, what is the Rockwell Hardness Scale? The Rockwell Hardness Scale is a technique to measure the hardness of the steel used to make knives.

There are different Rockwell scales because steel is used for many uses. In the knife-making industry, the hardness of the blades is measured following Rockwell Scale C, abbreviated as HRC or RC.

Understanding the hardness variations is crucial when purchasing knives. So, whether you’re a professional chef or a passionate collector, join us as we embark on this enlightening journey through the Rockwell Hardness Scale. Get ready to unravel the secrets that define the exceptional performance and long-lasting quality of your favorite blades.

What Is The Rockwell Hardness Scale For Knives?

The Rockwell hardness of knife steel determines how strong or hard the steel is. The rating shows how resistant the blade is to permanent deformation or penetration by another material. This information may correlate to the tensile strength, wear resistance and ductility of the steel.

The higher the number on the Rockwell Hardness Scale, the harder the steel, and the lower the Rockwell scale, the softer the steel. However, this does not mean steel with high HRC ratings makes high-quality knives.

The rating of softer steel range between 45-54 HRC, while harder steel ranges above 55 HRC. Rockwell hardness is important in the quality control of steel and the selection of steel to be used in different kinds of knives.

The Rockwell hardness rating of a knife blade is a key factor that determines its performance and longevity. A knife with a high Rockwell hardness rating, such as a rating of 59-60 HRC, is generally known for its exceptional hardness, sharpness, and ability to hold an edge for a long time. These knives are ideal for heavy-duty tasks such as chopping, slicing, and skinning, where durability and resistance to wear and tear are critical.

On the other hand, knives with low Rockwell hardness ratings, such as a rating of 48-52 HRC, tend to be more flexible and less brittle. These knives are often used for delicate tasks such as filleting, boning, and precision cutting, where the ability to bend and contour is more important than hardness and wear resistance.

For instance, consider a chef’s knife used in a professional kitchen. A high Rockwell hardness rating is essential in this scenario, as it ensures the knife will withstand the repeated, heavy-duty use and maintain its sharpness over time.

On the other hand, a fillet knife used in fishing would benefit from a lower Rockwell hardness rating, as it allows for greater flexibility and ease of use when handling delicate fish flesh.

The Rockwell hardness rating of a knife blade has a profound impact on its performance and ability to withstand various tasks and conditions. By selecting a knife with the appropriate Rockwell hardness rating, one can ensure that it is best suited for their specific needs and will perform optimally in their intended use.

How is the Rockwell Hardness Scale measured?

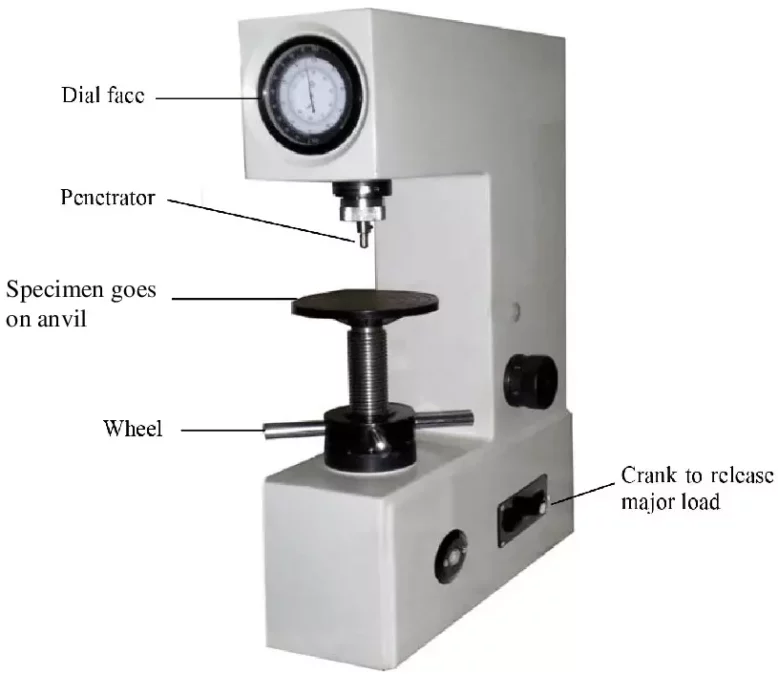

A tipped diamond which serves as an indenter is used to measure the hardness of steel because it falls under Scale C. Here is how the test calculates the hardness of steel:

- The steel is placed under an indenter with a starting force of 10 KGF. The depth caused by this force is recorded as the first reference.

- A force of 140 KGF is applied for a specified period, and the depth caused is recorded. Note that the first force is not removed as they apply the second force.

- The second force is removed, and the permanent depth is measured and recorded as the second reference point.

- The depth between the 10 KGF and the 140 KGF is the HRC rating of the steel.

The test process is not as simple as we made it sound because it involves the use of machines and complicated math calculations. But in simple terms, the Rockwell hardness scale is determined by measuring the permanent depth caused by a 150 KGF indenter on steel.

Difference between Rockwell Scale C and other Rockwell scales.

The Rockwell Scale is a system used to measure the hardness of materials. The difference between Rockwell Scale C and other Rockwell scales lies in the type of indenter and the depth of indentation.

Rockwell Scale C uses a diamond cone as an indenter and measures the depth of indentation to a shallower depth compared to other Rockwell scales, making it useful for measuring the hardness of harder materials.

On the other hand, other Rockwell scales, such as Rockwell B and Rockwell A, use a 1/16-inch steel ball or a spheroconical diamond indenter, respectively, and measure the depth of indentation to a greater depth, making them more suitable for softer materials.

The numerical values obtained from the Rockwell test can vary greatly between scales, hence it is important to specify which Rockwell scale is being used when reporting the hardness of a material.

What Does The Rockwell Hardness Scale Mean For Knives?

The hardness of steel determines the edge retention, ease of sharpening, and toughness of steel, which are major properties in determining the quality of knife blades. Here is how Rockwell’s Hardness rating affects the properties of steel.

Edge Retention

The edge retention of steel is directly proportional to the Rockwell rating. Therefore, the higher the Rockwell rating, the higher the edge retention. Knife blades made from hard steel hold a sharp edge for a long time, so you will not be required to sharpen your knives frequently.

Related: Knife Steel Blanks: Achieve Precision And Durability

Ease Of Sharpening

Steel with high HRC ratings is hard and, therefore, very challenging to sharpen because they have high wear resistance properties. Getting a razor-sharp edge will take a lot of time and energy.

Related: The Ultimate Guide To Knife Sharpness: The Art Of Cutting Like A Pro

Experts recommend that you hone your knives frequently, so they do not become dull quickly. However, if you do not have knife sharpening skills, consider blades with a lower Rockwell rating.

Toughness

Steels with a high Rockwell hardness like Maxamet are brittle, meaning that they chip and break easily when exposed to impact and pressure. If you want durable blades for tough applications, invest in knives made from steel with low Rockwell hardness. You will be required to sharpen them frequently, but they are less likely to break during use.

Different Rockwell ratings and their corresponding properties

Here’s a table that compares the different Rockwell hardness ratings and their corresponding properties:

| Rockwell Rating | Properties |

|---|---|

| 48-52 HRC | Flexible, less brittle, better suited for delicate tasks |

| 54-56 HRC | Good balance of hardness and flexibility, suitable for a wide range of tasks |

| 58-60 HRC | Hard, sharp, and able to maintain an edge for a long time, ideal for heavy-duty tasks |

It’s worth noting that the Rockwell hardness rating is just one of the many factors that determine the performance of a knife or tool. Other factors, such as blade shape, edge geometry, and material quality, can also have a significant impact on the suitability of a knife for a particular task.

Related: How Does A Butterfly Knife Differ From A Switchblade?

When choosing a knife, it’s important to consider the Rockwell hardness rating in the context of these other factors and to select the one that best meets your needs and preferences.

What is the Best HRC Rating for Kitchen Knives?

The most suitable HRC rating for kitchen knives is anywhere between 55HRC to 60 HRC. Soft and hard steels offer different properties, but this does not make either better than the other. The choice between steel with a high or low HRC rating depends on preference and knife needs.

Potential drawbacks of steels with low and high HRC ratings

Steels with low HRC ratings are often characterized by low hardness and poor wear resistance, making them vulnerable to deformation, cracking, and breakage under heavy loads and stress.

This can limit their applications in demanding industries such as construction and manufacturing, where the ability to withstand harsh conditions and high stress is crucial. Additionally, low HRC steels may also be more susceptible to corrosion, as they have weaker protective oxide layers compared to high HRC steels.

On the other hand, steels with high HRC ratings are known for their exceptional hardness and strength, but this property can also prove to be a drawback in certain scenarios. For example, high HRC steels can be difficult to machine and shape, as they are highly resistant to cutting and deformation.

This can increase production time and cost, as well as limit the ability to create intricate designs and shapes. Furthermore, high HRC steels may also have lower toughness, making them more prone to brittle failure under high stress and impact loads.

Therefore, the choice between steels with low and high HRC ratings often requires a careful consideration of the trade-offs between hardness, wear resistance, machinability, toughness, and cost.

The ideal HRC rating for a particular application depends on the specific requirements and conditions of the project and can vary greatly depending on the industry and intended use.

Therefore, there is no good or bad HRC rating. It all depends on your needs and the budget, Higher HRC knives tend to be more expensive than lower HRC knives like AUS 6 knives.

- DESIGN PHILOSOPHY - The Chefilosophi Series professional kitchen knife set from Brewin combines cutting edge kitchen technology with premium design philosophies; This five piece set of kitchen knives spares no attention to detail; For top shelf cooking knives that have been painstakingly crafted with expert chefs in mind, Brewin is obvious choice.

- RAZOR SHARP WITH DURABILITY - This stainless steel knife set features rock solid design crafted from durable materials; With a score of 56+ on the Rockwell hardness scale, our chef knife set professional solution uses ultra tough 1.4116 German stainless steel forged from a unified piece of rustproof metal; When you need kitchen accessories that will hold up under any conditions, choose Brewin.

- PREMIUM QUALITY - Each chef knife set has undergone stringent quality inspection and hundreds of hours of development with leading kitchen experts; This set of five chef knives is crafted to the highest standards with chefs and kitchen experts in mind; The Brewin promise is this; if we wouldn’t use this cooking knife set ourselves, we won’t sell it.

- ELEGANCE & BALANCE - Unlike some other chefs knives, The Chefilosophi Series from Brewin features perfectly balanced handles that are easier to hold; With a luxurious pakkawood natural texture and three reinforced anchor points, our chefs knife set has been engineered to last a lifetime.

- COMPLETE SET - Regarded as one of the best knife sets for people who demand all round practicality, the Chefilosophi Series comes with five sharp knives in luxurious gift packaging; With two eight inch knives as well as a santoku Japanese knife, our knife sets also include a five inch utility knife as well as smaller paring knife for peeling and prep.

- KITCHEN KNIFE SET - This high quality kitchen knife set is stain and rust resistant and can be used with high frequency or after long periods of inactivity to fully utilize the life of the knives.

- ALL-IN-ONE KITCHEN SET - 15-piece knife set includes. 8" chef's knife, 8" slicing knife, 7" Santoku knife, 8" serrated bread knife, 5" utility knife, 3.5" paring knife, 6 4.5" serrated steak knives, 1 kitchen shear and hard wood knife block with built-in knife sharpener.

- SHARP KNIFE SET - Each of HUNTER.DUAL knives is carefully tuned to be the sharpest it can be and wears a built-in sharpener.

- DISHWASHER SAFE - The knife set can be washed in the dishwasher, easy and quick to operate, and dry the knife set after cleaning for easy storage, not taking up space.

- CRAFTSMANSHIP - Non-Stick and Rust Resistant - With a black coating that prevents oxidation of the steel, the kitchen knife set will last a long time and remain non-stick and rust resistant. The ergonomically designed handle provides a comfortable grip and the handle will no longer loosen or fall off.

How to choose the right Rockwell rating based on personal preferences and needs

Choosing the right Rockwell hardness rating for a knife or tool depends on a number of personal preferences and needs. When making this choice, it is important to consider the intended use and desired properties of the blade, such as sharpness, toughness, and wear resistance.

For example, if a knife is intended for heavy-duty tasks such as chopping and slicing, a high Rockwell hardness rating, such as 58-60 HRC, is recommended. This will ensure that the blade is hard, sharp, and able to maintain its edge for a long time, even under heavy use.

On the other hand, if the knife is intended for delicate tasks such as filleting or precision cutting, a lower Rockwell hardness rating, such as 48-52 HRC, may be more appropriate. This will provide the blade with greater flexibility and resilience, making it better suited for handling delicate materials and avoiding breakage.

It is also worth noting that the Rockwell hardness rating alone does not determine the overall performance of a knife or tool. Other factors, such as blade shape, edge geometry, and material quality, can also play a crucial role in determining the suitability of a knife for a particular task.

When choosing the right Rockwell hardness rating for a knife or tool, it is important to consider the intended use, desired properties, and other relevant factors. By carefully evaluating these elements, one can select a Rockwell hardness rating that best meets their personal preferences and needs.

Can I test Rockwell hardness at home?

Rockwell hardness cannot be tested at home unless you have relevant equipment. It requires an indenter of 150 KGF of force, a piece of steel, special machines, and math calculation skills.

Is the Rockwell testing destructive?

Rockwell hardness testing causes a dent in the steel, but it is not destructive. The dent can also be unnoticeable depending on the tested material’s colour.

Conclusion

The Rockwell Hardness scale helps manufacturers maintain the quality of knives and helps knife users determine the quality of knives. There is no good or bad Rockwell hardness. The choice between low and high Rockwell rating knife steel depends on your preference and knife needs.

If you want a knife with excellent edge retention, go for a high HRC rating of RC60 and above. If you are looking for durable knives that are easy to sharpen and maintain, go for low HRC in the 50s.

If you do not have specific requirements, knives with HRC ratings between 54 and 56 HRC make a good choice because they are not too hard or too soft, and therefore their properties are well balanced. Lastly, always keep your knives sharp. If you need some tips on choosing a good sharpener for your cutlery, be sure to read our recent post on the topic.