Table of Contents

What is Maxamet steel?

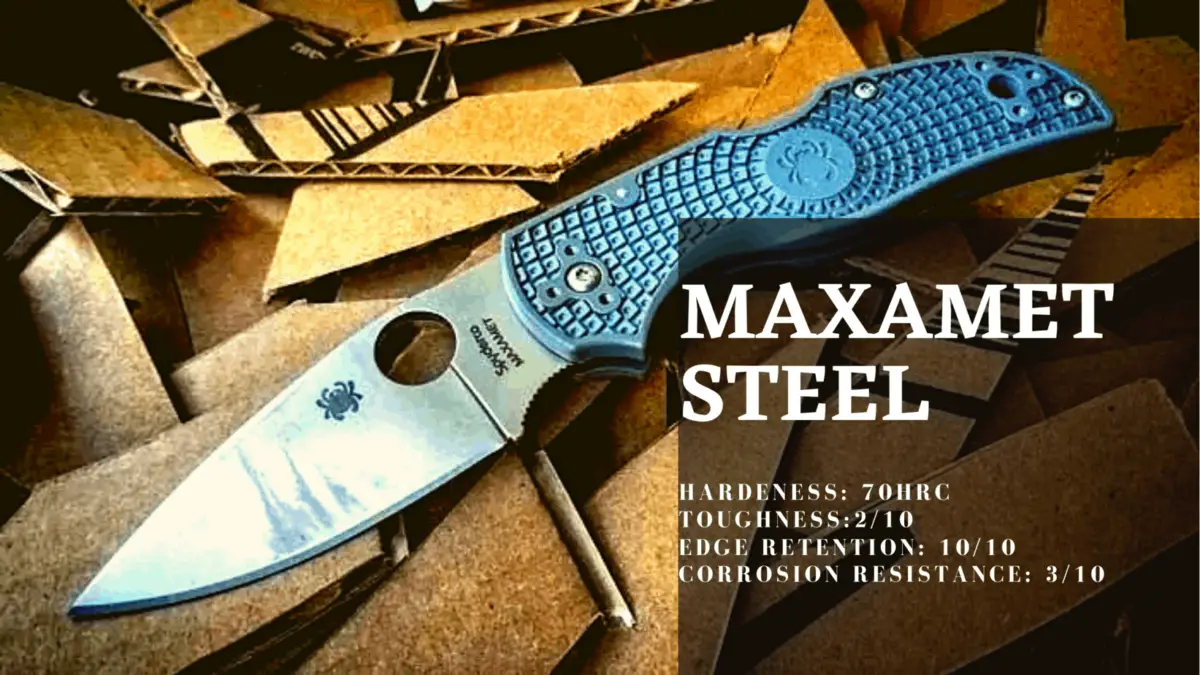

Maxamet steel, also known as Micro-Melt Maxamet, is a high-speed powder tool steel that is extremely hard. It is produced by Carpenter Technology Corporation, a company based in the US. Maxamet is recognized for making blades with outstanding edge retention and exceptional wear resistance.

Apart from knives, Maxamet is used to make tools that require extreme wear resistance like Punches, Taps, Broaches, and Industrial knives. Maxamet can also be used to make tools to be used in high temperatures.

Maxamet Steel composition (Maxamet Steel Chart)

- Carbon C 2.15%: Increases the edge retention, hardness ,and tensile strength. It also improves steel resistance to wear, abrasion ,and corrosion.

- Chromium Cr 4.75%: The formation of Chromium carbide Increases the hardness, tensile strength, and corrosion resistance of the blade.

- Cobalt Co 10.00%: Increases the strength of steel and hot hardness temperature.

- Manganese 0.30%: Improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

- Vanadium 6.00%: inhibits grain growth during elevated temperature processing and heat treatment, which enhances the strength and toughness of steel. It also forms carbides that increase wear resistance.

- Tungsten W 13.00%: Aids in the formation of Tungsten Carbide improving hardness and wear resistance.

- Sulfur S 0.07%: Improves toughness and machinability but is generally considered an impurity.

- Silicon Si 0.25%: Increases strength and heat resistance.

Maxamet steel properties

Maxamet Hardness

Maxamet has a Rockwell hardness of up to 70 HRC, this is an outstanding feature of this steel. The high level of hardness is associated with the mix of Carbon, Vanadium, Cobalt, and Tungsten. Tungsten improves the hot hardness of the steel even at higher temperatures.

Very few knife steels can come close to the hardness of the Maxamet steel. CPM Rex 45 steel edges closer with a Rockwell hardness of 67 HRc but CPM Rex 121 steel beats it with a hardness of 71 HRc

Maxamet Edge retention

Maxamet steel has outstanding edge retention and this is due to the high Rockwell hardness. Maxamet blade steel edge retention is better than most knife steel apart from Rex 121 Blade steel.

A Maxamet knife blade will maintain its sharp edge for a very long time. Therefore, if you are looking for a knife to use in situations that do not give frequent sharpening time, narrow down to varieties of Maxamet steel.

Maxamet Wear resistance

Maxamet steel knives have incredible wear resistance due to the higher Rockwell hardness, they do not wear and tear easily, even with frequent usage. The addition of Cobalt and Tungsten also greatly improves its wear resistance.

Maxamet Corrosion resistance

One of the downsides of Maxamet is its poor corrosion resistance as it contains low amounts of chromium in its composition. Maxamet is not stainless as the chromium contents do not meet the requirements of stainless steel and hence offer poor corrosion resistance.

Maxamet knives’ corrosion resistance ability is similar to that of D2 knives, thus you will need to take care of them to avoid rusting and staining.

Maxamet Toughness

Maxamet steel offers a low level of toughness. The level of toughness is lower than most other conventional or powder-produced steel with a Rockwell hardness of 65 HRC and below.

Maxamet blade steel toughness is comparable to that of ZDP 189, slightly better than Rex 121 steel. With its toughness level, knives made with Maxamet steel can still be used but not for challenging applications without breaking or chipping.

Sharpening Maxamet

Due to the high Rockwell hardness, Maxamet steel is very challenging to sharpen. Getting an edge is one of the most significant challenges you will experience with this super hard steel.

Machinability

Maxamet blade steel is a bit difficult to machine compared to other conventionally produced steels with lower Rockwell hardness. It is however easier to machine when compared to other tungsten carbides that are extremely hard.

Maxamet Steel Comparison

Maxamet vs S30V

Maxamet steel is better than S30V steel in edge retention and wear resistance. Maxamet is able to perform better than S30V in these aspects due to its incredibly high Rockwell hardness and the presence of a large number of hard vanadium carbides in its alloy composition.

A significant difference between S30V and Maxamet is that S30V is stainless steel with excellent corrosion resistance while maxamet is non-stainless steel prone to rusting when exposed to corrosive environments.

S30V steel is produced through a particle metallurgy process, which yields fine and uniform carbide distribution in its alloy enhancing its toughness. S30V steel offers more than twice the toughness of Maxamet steel thus S30V steel knives are less likely to experience chipping, cracking, or breaking compared to maxamet knives.

CPM S30V steel knives are also easier to sharpen than Maxamet knives. Due to excellent wear resistance and high Rockwell hardness, sharpening it will require lots of time and effort.

Maxamet vs M4 steel

The major difference between Maxamet and M4 steel is in edge retention; Maxamet steel offers outstanding edge retention, twice that of M4 Steel. The exceptional edge retention of Maxamet is due to it being super hard at about 70 HRC.

M4 steel provides more than twice the toughness of Maxamet; it achieves this due to its well-balanced alloy composition and powder metallurgy production process that yields finer microstructure that is less susceptible to chipping and cracking.

Maxamet and M4 steel are both non-stainless steel with average corrosion resistance; however, M4 steel may be better than Maxamet at a reduced hardness due to its alloy composition that is high in Molybdenum that makes up for the reduced chromium elements.

M4 steel is better than Maxamet for an EDC as it offers a great balance in toughness, edge retention, corrosion resistance, and ease of sharpening. CPM M4 knives can be used in tough applications, while most Maxamet knives will chip or break under such applications.

Maxamet vs S110V

The main difference between Maxamet and S110V steel is that S110V steel is stainless steel while Maxamet is non-stainless steel. S110V steel is able to achieve high corrosion resistance due to 15% chromium content compared to 4.75% chromium content in Maxamet.

CPM S110V is produced through the crucible’s particle metallurgy process that produces fine and uniform carbide distribution compared to that of Maxamet. The fine distribution of carbides enables S110V steel to achieve better toughness and grindability compared to Maxamet.

Maxamet knife is better than S110V steel knife in edge retention and wear resistance. Maxamet is able to achieve incredible edge retention due to the presence of a large number of Vanadium Carbides and a higher Rockwell hardness compared to CPM S110V steel.

The edge retention of Maxamet is only rivaled by a few knife steels like Rex 121 and CPM 15V Steel. Due to the added wear resistance, sharpening maxamet is extremely difficult, and thus S110V outshines it in ease of sharpening.

Maxamet vs Magnacut

Magnacut steel is better all-around knife steel compared to Maxamet steel. While Maxamet heavily focuses on Rockwell hardness, edge retention, and wear resistance, CPM Magnacut steel is aimed at providing a balanced approach to edge retention, toughness, and corrosion resistance.

Maxamet is able to achieve a higher Rockwell hardness than MagnaCut steel, thus offering better edge retention and wear resistance. Maxamet knife steel edge retention is twice that of Magnacut knife steel.

Magnacut steel is better than Maxamet in corrosion resistance as it lacks Chromium carbides in its alloy composition. The lack of chromium carbides means that the chromium in its alloy exists purely in solution form, giving it the maximum level of corrosion resistance. Molybdenum additions also improve its corrosion resistance.

Magnacut knife steel outshines Maxamet knife steel in toughness. Magnacut toughness is more than twice that of Maxamet. Magnacut achieves outstanding toughness due to the powder metallurgy production process and the lack of brittle carbides like Chromium carbides.

Maxamet vs S45VN

Maxamet steel is better than S45VN steel in edge retention and wear resistance. Maxamet offers more than twice the edge retention of S45VN steel; its wear resistance is also excellent and will outlaw S45VN steel. Maxamet edge retention and wear resistance is due to the higher Rockwell hardness and the high amount of Vanadium Carbides.

A key notable difference between Maxamet and S45VN is that Maxamet is not stainless steel while S45VN steel is stainless with excellent corrosion resistance.S45VN stainless steel knives are less susceptible to rust and corrosion. S45VN corrosion resistance is due to the high amount of Chromium elements.

S45VN steel offers better toughness than Maxamet; its toughness is about twice that of maxamet. The higher toughness of S45VN is due to the particle metallurgy production and the lack of a vast amount of brittle vanadium carbide that is hugely present in Maxamet blade steel.

Overall S45VN steel takes a balanced approach to all the aspects like edge retention, toughness, corrosion resistance, and ease of sharpening, it is balanced knife steel than Maxamet which only has an edge in edge retention and wear resistance.

Maxamet vs M390

The main difference between Maxamet and M390 steel is that M390 is stainless steel while Maxamet is non-stainless steel. Bohler M390 stainless steel contains about 18% chromium elements in its alloy composition which gives it excellent stainless properties.

Maxamet steel has a higher Rockwell hardness than M390 steel. The higher Rockwell hardness gives Maxamet excellent edge retention and wear resistance. Maxamet is able to achieve better edge retention than M390 due to the availability of more Vanadium carbides.

Bohler M390 is better than Maxamet in toughness. Bohler M390 steel is produced through a powder metallurgy process, this results in a fine and uniform carbide distribution which greatly improves its toughness despite achieving a high Rockwell hardness.

M390 steel knives are less likely to experience chipping and cracking when compared to maxamet knives due to the increased toughness. M390 steel knives will also be much easier to sharpen than Maxamet knives due to the reduced hardness.

Is Maxamet good knife steel?

Maxamet is good knife steel due to its high Rockwell hardness. It offers excellent edge retention and outstanding wear resistance. The major downside is that it is not stainless steel and may be prone to chipping.

Maxamet steel is an amazing alloy that offers unique high hardness and moderate toughness properties. A knife enthusiast will argue that micro melt maxamet steel is that steel that you will never go wrong with for your knife, which is very true.

It is a popular choice in the knife industry though a bit expensive due to the advanced powder metallurgy technology used to produce it. Maxamet blade material has been heavily used by Spyderco.