What is MagnaCut Steel?

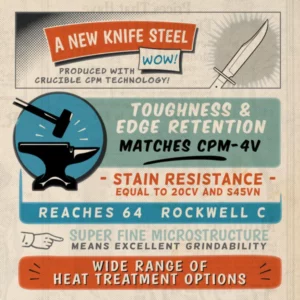

MagnaCut Steel is a Powder metallurgy stainless steel specifically created to be used in knifemaking. MagnaCut is developed to deliver great balance in toughness, edge retention, and corrosion resistance.

The steel was named MagnaCut to fit in the category of other high-speed steels from Vanadium Alloys Steel Company (VASCO) with Cut in their name. Magna is a Latin name that means awesome or great, therefore, it is awesome knife steel.

CPM MagnaCut steel is the idea of Larrin Thomas, a renowned steel author but produced by Crucible Industries in 2021. This steel features a unique design that aims to reduce the Chromium in its composition, in order to dissolve the available chromium carbides during heat treatment.

The end product contains small hard carbides from Vanadium and Niobium in its composition because the large amounts of softer chromium carbides will have been dissolved.

The perfect balance of Chromium and Carbon in its alloy composition gives it great wear resistance and toughness over most existing knife steels.

Is MagnaCut Stainless?

MagnaCut steel is a unique type of stainless steel as it contains less than the recommended chromium content of other known stainless steel.

Despite the reduced chromium content, MagnaCut steel offers great corrosion resistance compared to other non-stainless, and stainless steel. The reduced Chromium carbides give way for Chromium to better corrosion resistance.

CPM MagnaCut Steel Composition

| Element | Percentage |

|---|---|

| Carbon C | 1.15% |

| Chromium Cr | 10.70% |

| Molybdenum Mo | 2.00% |

| Vanadium V | 4.00% |

| Nitrogen N | 0.20% |

| Niobium Nb | 2.00% |

- Carbon: Increases the edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

- Chromium: Formation of Chromium carbides Increases hardness, corrosion resistance, tensile strength and toughness of the blade.

- Molybdenum Mo: It improves machinability and hardness.

- Vanadium V : Increase wear resistance and toughness, it also improves corrosion resistance. High vanadium content enables formation of Vanadium Carbides.

- Nitrogen N : Increases hardeness and corrosion resistance.

- Niobium Nb : Improves toughness of the steel. Aid information of Niobium carbides.

Properties of CPM MagnaCut steel

MagnaCut Steel Hardness

The Rockwell hardness of CPM MagnaCut steel is 62.5-64HRC depending on the heat treatment used. The idea behind this steel was to give it high hardness and excellent corrosion resistance, even with reduced Chromium, and it achieved precisely that.

MagnaCut Steel Toughness

Hard steels are supposed to be brittle, so we will not be surprised if you have already placed this steel in the poor toughness bracket. However, this is not the case with MagnaCut steel, It is one of the steel that offers excellent hardness and toughness balance.

How tough is MagnaCut?

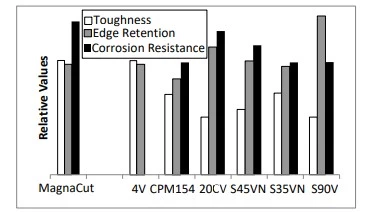

CPM Magnacut steel toughness is better than most other steel on the market, its toughness is on par with CPM 4V and slightly lower than Nitro V steel. Very few steels can beat MagnaCut toughness, these include the likes of 3V, CPM CruWear, AEB-L, 14C28N, LC200N and 420HC

Because of the excellent toughness, knives made from this steel can withstand impact and pressure from tough applications like cutting hardwood. Some YouTube videos show nail chop without the blade chipping or rolling.

MagnaCut Steel Edge retention

Another area of excellence for this MagnaCut steel is edge retention, which is expected because of its high hardness. Blades made from this steel have been found to have the same edge retention as blades made from high-end steels like CPM 4V, S35VN, and CPM CruWear.

Expect MagnaCut knives to maintain a sharp edge even after using them to cut things like ropes and cardboards. Additionally, MagnaCut steel has great edge stability; this is the capability of blade steel to maintain high toughness, wear-resistance, and Hardness.

| Steel | HRC | CATRA Testing % |

| MagnaCut | 62.5 | 135 |

| CPM 20CV | 61.5 | 155 |

| S35VN | 61 | 130 |

| CPM 154 | 61 | 120 |

| 440C | 56 | 100 |

MagnaCut Steel Corrosion resistance

With reduced Chromium content, MagnaCut steel is expected to offer poor corrosion resistance, but it beats the expectations of many by providing excellent corrosion resistance. According to the crucible datasheet, the corrosion resistance of MagnaCut outperforms that of other stainless steel like CPM 20CV, S45VN, S35VN, and S110V.

According to Larrin Thomas the developer, MagnaCut is able to achieve this high performance in corrosion resistance almost close to that of Vanax and LC200N due to reduced chromium carbides.

Chromium carbides are always present in most stainless steel due to the high amount of Chromium in their alloy composition.

Sharpening MagnaCut

MagnaCut steel has a fine microstructure that should make it easy to sharpen, but at the same time, has hard Vanadium and Niobium carbides for edge retention. Fortunately, the fine microstructure takes the lead in the ease of sharpening.

Knifemakers and users have reported that this steel is easy to work with and sharpen. Therefore, you can get a sharp edge quickly with simple sharpening tools like Shapton glass stones.

Sharpening MagnaCut has been compared to sharpening CPM 154 steel only with a bit harder polishing. Mastering the sharpening process is a skill that anyone can learn though.

MagnaCut Heat Treat

Dr. Larrin Thomas the Creator of MagnaCut steel has a handy guide on the best possible way to heat treat MagnaCut steel in his main article. In summary MagnaCut, heat treatment is not complicated.

The general recommended Heat treatment of MagnaCut for optimal hardness, toughness, and corrosion resistance is 2050°F austenitize in plate/oil quench and a 2×2 hour 350°F temper which will result in a hardness of about 61 to 62.5 Rc.

It is worth noting you can achieve high hardness if you follow another heat treatment cycle but will be in favor of edge retention over other performance aspects like corrosion resistance and toughness.

CPM MagnaCut Steel Comparison

CPM MagnaCut vs CPM 4V

The equivalent of CPM MagnaCut can be CPM 4V, which is non-stainless steel. Both steels offer excellent toughness at different levels of hardness and are therefore highly resistant to breaking or chipping.

MagnaCut and 4V steel both provide the same level of edge retention. However, MagnaCut provides better corrosion resistance, but it performs like an improved version of CPM 4V.

MagnaCut vs CPM 3V

The main difference between MagnaCut Steel and CPM 3V steel is that MagnaCut steel is stainless steel while CPM 3V is non-stainless steel. MagnaCut knives offer impressive corrosion and stain resistance compared to CPM 3V knives.

CPM 3V steel however narrowly outperforms MagnaCut steel when it comes to toughness. CPM 3V is specifically made to be a high toughness and wear-resistant tool steel following the Crucible Particle Metallurgy process.

Both MagnaCut and CPM 3V steel offer an identical level of edge retention. It is worth noting that sharpening Magnacut is easier than sharpening CPM 3V and this can be attributed to the excellent wear resistance of CPM 3V.

Related – 6 New Knife Steels To Look Out For

MagnaCut vs 20CV

The main difference between MagnaCut steel and 20CV steel is that MagnaCut steel offers twice the performance of 20CV steel in toughness. The toughness of MagnaCut steel is better than most other steels, including the likes of CPM S45VN, Vanax, and VG10.

20CV steel offers slightly better edge retention than MagnaCut. The edge retention of 20CV is Identical to that of Bohler M390 stainless steel and CTS 204P stainless steel. Keep in mind the HRC is highly determinant of the edge retention you will get on both knife steels.

Both 20CV steel and MagnaCut steel will offer impressive corrosion resistance. However, MagnaCut slightly beats 20CV Steel in stain resistance due to its impressive blend and balance of alloying elements despite having few Chromium elements.

Another noticeable difference between 20CV and MagnaCut is that despite both achieving a higher hardness of over 61HRC, MagnaCut steel is incredibly easy to sharpen, 20CV steel on the other hand is difficult to sharpen.

Read Our Recent Article about Dasmascus Knife Steel

MagnaCut vs CruWear

The main difference between MagnaCut steel and CruWear steel is that MagnaCut steel is stainless steel while CruWear is non-stainless steel. MagnaCut offers close to twice the corrosion resistance of CruWear steel.

The other notable difference is that CruWear steel knives slightly outshine MagnaCut steel knives in toughness. The difference in toughness between MagnaCut steel and CruWear steel can be attributed to the reduced Chromium Elements in CPM CruWear.

Both MagnaCut and CruWear offer the same level of edge retention. Their edge retention is similar to that of CPM S35VN, D2, and CPM 4V. They are also equally easy to sharpen with normal sharpening abrasive tools.

MagnaCut vs M390 steel

M390 steel is produced by Bohler Uddeholm while CPM MagnaCut is a product of Crucible. MagnaCut steel is tougher than M390 steel due to its carefully handpicked alloy composition, MagnaCut steel is about twice as tough as M390 steel.

M390 alloy composition however enables it to provide excellent edge retention, it beats MagnaCut in edge holding slightly. MagnaCut will be the easier steel to sharpen over M390 due to the relatively finer microstructure.

In terms of corrosion resistance, the performance of both steels are matched however, the MagnaCut takes a slight edge over the already excellent Bohler M390 steel.

MagnaCut vs Vanax

Vanax steel is slightly better than MagnaCut steel in Edge retention and Corrosion resistance but by a very slight margin. What is more surprising is that MagnaCut despite not containing high chromium percentage almost matches the Nitrogen based Vanax corrosion resistance properties.

In terms of edge retention, the same thing happens as Vanax slightly beats MagnaCut steel with a very minimal margin. Where MagnaCut shines over Vanax however is in toughness. MagnaCut blade steel will last you longer on tougher applications than Vanax blade steel.

A MagnaCut steel knife will also be much easier to sharpen and get a good edge on it than it will be to sharpen a Vanax steel knife, or many other knife types.

MagnaCut vs LC200N

LC200N also known as Z-Finit is nitrogen-based steel made by ZAPP. It is adopted in most Spyderco Knives intended to be used in corrosive environments. LC200N steel offers impressive corrosion resistance over other steels in the market apart from its nitrogen-based counterpart Vanax steel.

It is remarkable what Larrin Thomas achieved with the alloy composition of MagnaCut steel, Despite the low chromium percentage, its performance in corrosion resistance is highly comparable to LC200N steel. LC200N wins by a slight margin, quantitatively 0.5 of a margin over MagnaCut.

LC200N steel also beats MagnaCut in toughness by a much bigger margin. LC200N/ Z-finit steel knife will outlast MagnaCut knives in toughness.

In terms of edge retention, MagnaCut steel outperforms LC200N due to its fine microstructure containing a better blend of elements that give it great toughness while still maintaining a good edge.

MagnaCut vs S45VN

MagnaCut Steel is better than CPM S45VN in almost all aspects. MagnaCut steel is about twice as tough as CPM S45VN steel. It beats S45VN in corrosion resistance despite MagnaCut low chromium percentage. According to Larrin the excellent corrosion resistance of MagnaCut is due to the elimination of chromium carbides.

S45VN however outperforms MagnaCut slightly in edge retention. This can be attributed to the higher percentage of Carbides over MagnaCut.

It is worth noting that a bigger percentage of the carbides are the Chromium carbides while in MagnaCut Vanadium carbides take the bigger percentage.

Is MagnaCut good knife steel?

The high toughness makes it suitable for making knives with big blades, and the fine microstructure gives its thin blades a very sharp edge. In both instances, the blades won’t chip or break easily when used for challenging applications.

Knives with MagnaCut Steel

- Spyderco Native 5 Salt Knife with CPM-MagnaCut

- Hogue Deka ABLE with CPM MagnaCut

- LionSteel/Emerson Karambit Knives with CPM MagnaCut

- Rockwall Thumb Stud with CPM MagnaCut

- Pro-Tech TR-3 Tactical Response III with CPM MagnaCut

Shop for CPM MagnaCut Steel knives on Amazon

Sources

“CPM Magnacut – The Next Breakthrough In Knife Steel – Knife Steel Nerds”. Knife Steel Nerds, 2021, https://knifesteelnerds.com/2021/03/25/cpm-magnacut/. Accessed 18 Dec 2021.

“::Crucible Industries:: Home :: You & Us”. Crucible.Com, 2021, http://www.crucible.com Accessed 18 Dec 2021.

Microsoft Word – CPM MagnaCut datasheet12.docx (nsm-ny.com)

You can buy MagnaCut from Niagara Specialty Metals

Check Hardness Recommendation for CPM MagnaCut steel by Larrin Thomas