Table of Contents

What is S45VN Steel?

CPM S45VN Steel is martensitic stainless steel, designed as an improvement of S35VN steel by Crucible. Its chemical composition has been rebalanced to make it better.

It contains more Nitrogen for better hardness, more chromium for better corrosion resistance, high vanadium content for excellent edge retention and wear resistance, and more niobium for easy machinability.

CPM S45VN steel is among the latest steels on the market, developed around 2019; it is already popular among knife makers and other industries. Knifemakers like Spyderco and Spartan Blades have already adopted S45VN stainless steel and are updating their lineup with this new steel.

Spyderco’s famous ParaMilitary 2 and Para 3 knives previously made by CPM S30V and later updated with S35VN stainless steel are slowly being updated to the latest CPM S45VN stainless steel.

It is commonly used to make blades for kitchen, hunting, combat, and diving knives in the knife industry. It is also used in the machinery industry to make feed screws, valve parts, pelletizing equipment, and food processing components.

S45VN Steel Composition

| Element | Content (%) |

|---|---|

| Carbon C | 1.48% |

| Chromium Cr | 16.00% |

| Nitrogen N | 0.15% |

| Vanadium | 3.00% |

| Molybdenum Mo | 2.00% |

| Niobium Nb | 0.50% |

- Carbon C 1.48%: Increases edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

- Chromium Cr 16.00%: More than 11% of Chromium is what makes “stainless” steel. The formation of Chromium carbides Increases the hardness, tensile strength, and toughness of the blade.

- Molybdenum Mo 2.00%: It improves machinability and hardness.

- Vanadium V 3.00%: Increases wear resistance and toughness, it also improves corrosion resistance. High vanadium content enables the formation of Vanadium Carbides.

- Nitrogen Ni 0.15%: Increases hardness and corrosion resistance.

- Niobium Nb 0.50%: Improves the toughness of the steel.

Properties of S45VN Steel

S45VN Steel Hardness

The hardness of CPM S45VN is 61-63HRC as per the Rockwell hardness scale. The hardness level differs from the heat treatment used by the manufacturer. Therefore, there is a possibility of getting higher hardness. The increased hardness over its predecessors like S30V and S35VN is based on the addition of Nitrogen in S45VN alloy.

CPM S45VN Steel Edge Retention

Because of the high carbon content in its composition, CPM S45VN offers better edge retention. The difference in edge retention between this steel and its predecessor, S35VN, is felt when cutting tough things like cardboard and ropes.

With that said, if you are in search of a knife that will hold an edge for a long time irrespective of use, the varieties of CPM-S45VN will not disappoint you.

CPM S45VN Steel Corrosion Resistance

As already stated, S45VN contains high amounts of chromium(16%) making it stainless steel. Some of the Chromium elements are used to form fine chromium carbides with a remainder for rust resistance. With excellent edge retention, knives made from this steel will not stain or corrode when used in humid and wet environments.

CPM S45VN Steel Wear Resistance

This steel offers better wear resistance than S35VN. The increased Niobium components combine with Carbon to form hard niobium carbides that increase the wear resistance.

The high levels of vanadium in its composition also contribute to the quality of wear resistance. Because of this property, CPM S45VN knives last for many years without deforming.

S45VN Steel Toughness

One of the main reasons for upgrading the S30V to the CPM-S45VN is to improve its toughness, and S45VN is tougher but falls below the S35VN. The Crucible Powder Metallurgy manufacturing process used, plus its chemical composition makes this steel quite tough. For that reason, S45VN blades don’t break or chip easily due to impact or tough applications.

S45VN Steel Sharpening

The ease of sharpening steel is determined by its hardness. With a hardness of 61-63HRC, CPM S45VN is challenging to sharpen. It will take you more time to effort to get a razor-sharp edge with this steel.

The good news is, it holds an edge for a long time, and therefore you will not be required to sharpen it frequently.

Machinability of CPM-S45VN Stainless Steel

Most high-end steels are not easy to work with, but the narrative is different with S45VN stainless steel. Knifemakers love this steel because it is easy to polish and grind. It requires less power and energy to make quality knife blades. This aspect can be attributed to the addition of Niobium which increases machinability.

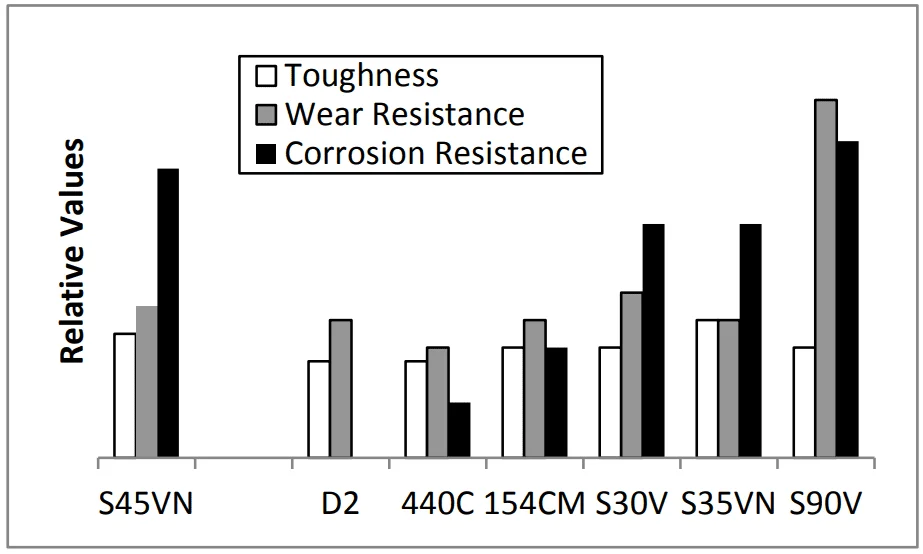

CPM S45VN Steel Chart, Equivalents, and Comparison

S45VN Equivalent

The equivalent of S45VN stainless steel is its predecessor S35VN. These steels have similar chemical composition only that, S45VN contains increased amounts of Chromium and NItrogen. S45VN thus offers better wear resistance, edge retention, and corrosion resistance.

The addition of nitrogen in most nitrogen-based steel like CTS BD1N, LC200N, and Nitro V steel has always yielded better performance in terms of corrosion resistance and edge retention.

S45VN vs 440C

The main difference between S45VN steel and 440C steel is that S45VN steel outshines 440C steel in toughness, edge retention, wear resistance, and corrosion resistance. However, it is easier to sharpen a 440C blade steel.

S45VN steel offers about four times more toughness than that of 440C stainless steel. According to CATRA (Cutlery& Allied Trades research association), S45VN steel offers about 43% more performance than 440C in cutting and edge retention.

S45VN vs CTS BD1N

The main difference between CPM-S45VN steel and CTS BD1N steel is that S45VN steel offers better Edge retention and toughness. CTS BD1N stainless steel on the contrary provides better performance in corrosion resistance and wear resistance.

CPM S45VN stainless steel’s better performance over CTS BD1N stainless steel in toughness can be attributed to the reduced amount of chromium carbides which are highly brittle when subjected to tougher applications.

The high amount of chromium elements in CTS BD1N steel and the addition of nitrogen in its alloy gives CTS BD1N blade steel better performance in terms of corrosion resistance over most stainless steel blades including S45VN stainless steel.

CTS BD1N blade steel corrosion resistance is comparable to 440A stainless steel and Sandvik 14C28N steel.

While CTS BD1N blade steel can achieve higher hardness than S45VN blade steel; it does not necessarily provide better edge retention than S45VN steel. The improved edge retention in S45VN blade steel can be attributed to the presence of vanadium carbides which CTS BD1N lacks.

S45VN vs 20CV

The main difference between the S45VN steel blade and the 20CV steel blade is that the S45VN steel blade offers slightly better performance in toughness. CPM 20CV steel blades on the other hand offer better performance than CPM S45VN in edge retention and corrosion resistance.

Despite both CPM 20CV and CPM S45VN offering an almost identical Rockwell hardness range of 58-61HRC, S45VN stainless steel blades will offer better toughness due to reduced chromium carbides which are highly brittle.

CPM 20CV composition contains a higher percentage of vanadium, chromium, and carbon elements compared to S45VN composition. These elements allow the formation of a high volume of carbides which benefits it in edge retention and wear resistance.

The 20% Chromium elements in 20CV stainless steel also improve its corrosion resistance over S45Vn stainless steel. Looking at all the properties, CPM 20CV steel is a better performer than S45VN steel, however, S45VN stainless steel offers a great balance between performance and usability as it is easier to sharpen.

Related – S45VN Vs M390

See Also: Spyderco SPY27 steel review, a new exclusive Spyderco Steel

Pros and Cons of S45VN stainless steel

Pros of S45VN steel

- Excellent Edge Retention

- Excellent Corrosion Resistance

- High Hardness up to 61 HRC

- Great Wear Resistance

Cons of S45VN Steel

- Relatively Low Toughness compared to S35VN

- Hard to sharpen

- New steel hence may be more expensive

Is S45VN Steel good?

CPM S45VN stainless steel is a good knife steel. It offers excellent edge retention, great wear resistance, tremendous corrosion resistance, and moderate toughness. The only downside is that it is challenging to sharpen, but since it retains sharpness for a long time, you will not require to sharpen it often.

What’s more, it has high machinability, hence knife makes find it easy to cut, grind and polish. Because of the easy machinability, the cost of production goes down, which translates to high-quality, affordable knives.