Table of Contents

Two popular blade choices among professionals and enthusiasts are S45VN steel and M390 steel. Both are known for their exceptional performance and durability, but how do they compare to each other?

In this article, we will compare S45VN steel and M390 steel in terms of composition, toughness, edge retention, corrosion resistance, ease of sharpening, and price to help you make an informed decision

About M390 Steel

M390 steel is a premium martensitic stainless steel produced by Bohler in Austria using the powder metallurgy process. It is known for its excellent wear resistance and corrosion resistance, making it a popular choice among professionals and enthusiasts.

Bohler M390 steel is a pricier option compared to other knife steels, but its superior performance makes it worth the investment for many users.

About S45VN Steel

CPM S45VN steel is martensitic stainless steel produced by Crucible Industries using the CPM (crucible particle metallurgy) process. It offers a balanced performance in terms of toughness, edge retention, and corrosion resistance.

S45VN stainless steel is an iteration of S30V and S35VN steel, and is known for its versatility and reliability in a variety of applications. Overall, S45VN is a high-quality steel that is well-suited for EDC knives and many different types of knives.

M390 vs S45VN: Comparison Table

| Specification | M390 Steel | S45VN Steel |

|---|---|---|

| Composition | Carbon 1.90% Chromium 20.00% Molybdenum 1.00% Silicon 0.40% Vanadium 4.00% Manganese 0.30% Tungsten 0.60% Silicon 0.70% | Carbon 1.48% Chromium 16.00% Molybdenum 2.00% Nitrogen 0.15% Vanadium 3.00% Niobium 0.50% |

| Rockwell Hardness | 60-62 HRC | 59-61 HRC |

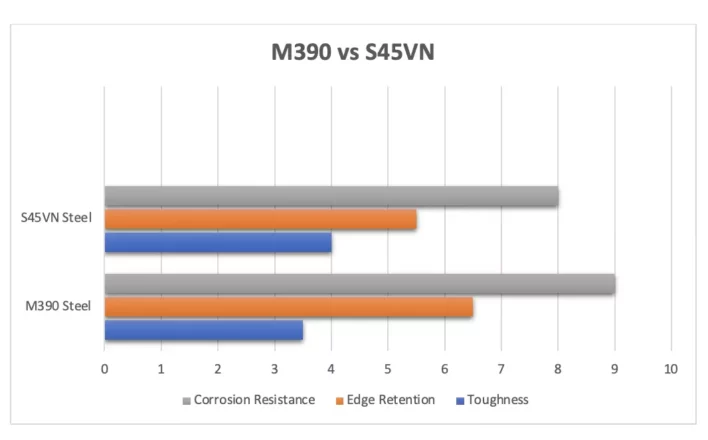

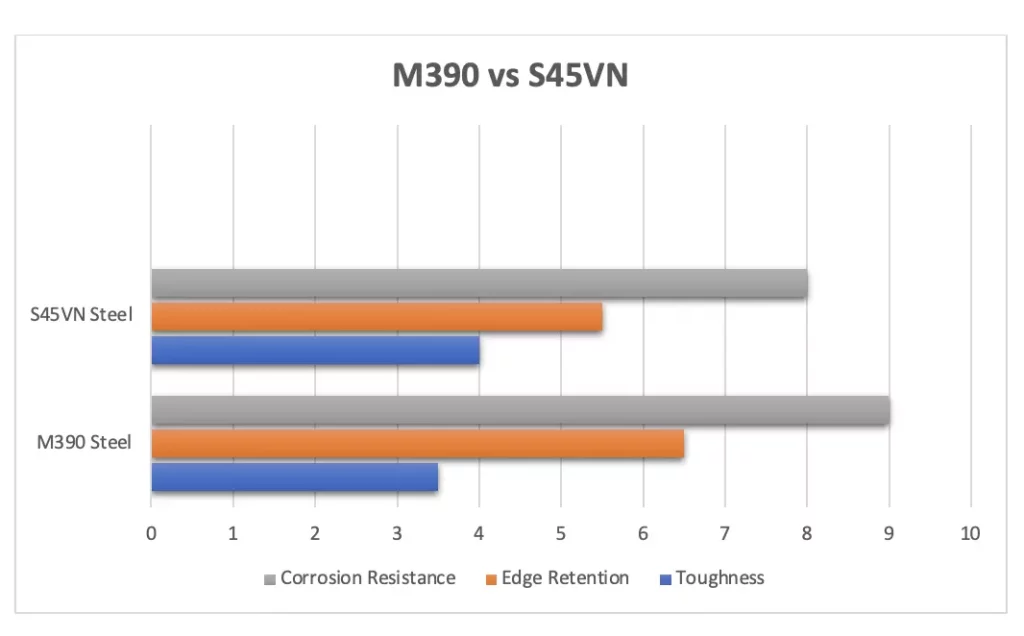

| Edge Retention | 6.5/10 | 5.5/10 |

| Toughness | 3.5/10 | 4/10 |

| Corrosion Resistance | 9/10 | 8/10 |

| Ease of Sharpening | Hard | Moderate |

| Price | Expensive | Mid-range |

Toughness

Toughness is a measure of a material’s ability to absorb energy and deform without breaking. In the context of knife steel, toughness is an important characteristic because it determines how well a knife can withstand impacts and resist breaking or chipping.

When comparing S45VN and M390 steel in terms of toughness, it’s important to note that S45VN has slightly better toughness due to its production process (CPM) and its specific chemical composition that even contains Niobium.

However, it’s worth noting that the M390 is also decently tough steel and S45VN doesn’t beat it by far. Ultimately, both S45VN and M390 offer average toughness and are not the best in the market.

Edge Retention

Edge retention is a measure of how well a knife can maintain its sharpness over time. In terms of edge retention, M390 steel is slightly better than S45VN due to its high Vanadium and chromium carbides in its alloy composition that results in a higher Rockwell Hardness.

These elements help to create a harder and more durable edge that can retain its sharpness for longer periods of time. While S45VN is also a high-quality steel that offers good edge retention, it’s not quite on par with M390 in this regard.

Corrosion Resistance

Both M390 and S45VN are stainless steels that are known for their excellent corrosion resistance. This means that they are resistant to rust and other forms of corrosion, making them ideal for use in damp or humid environments.

When it comes to corrosion resistance, M390 steel has a slight advantage over S45VN. M390 is known for its excellent corrosion resistance, thanks to its high chromium content (20.00%) and the presence of other corrosion-resistant elements in its alloy composition.

While S45VN is also a high-quality steel that offers very good corrosion resistance, it’s not quite on par with M390 in this regard. It’s worth noting that both S45VN and M390 steel offer very high levels of corrosion resistance, making them ideal choices for outdoor and maritime applications where corrosion is a concern.

Ease Of Sharpening

When it comes to ease of sharpening, S45VN steel has an advantage over M390 steel. S45VN is known for its improved grindability thanks to its CPM production process, which results in a finer and more uniform grain structure. This makes the S45VN easier to sharpen and allows for a more precise edge.

While Bohler M390 is also a high-quality steel that can be sharpened to a very fine edge, it’s not quite as easy to sharpen as S45VN. This is due in part to its high Vanadium and chromium carbides, which make it harder and more durable but also more challenging to work with.

Intention of use

Both S45VN and M390 steel are highly versatile and can be used for a wide range of applications. S45VN is known for its improved grindability and ease of sharpening, making it an excellent choice for everyday carry knives, kitchen knives, and other tools that may require frequent sharpening. It’s also a tough and durable steel that can withstand heavy use and wear.

M390, on the other hand, is known for its excellent wear resistance, edge retention, and corrosion resistance. It’s a popular choice for high-end kitchen knives, outdoor knives, and other tools that require durable and highly corrosion resistant steel.

Price

When it comes to price, M390 steel is generally more expensive than S45VN steel. This is due in part to its higher wear resistance, edge retention, and corrosion resistance, which make it a more premium choice for certain applications.

S45VN is also a high-quality steel that offers good performance at a more affordable price point. Ultimately, the choice between S45VN and M390 steel will depend on your specific needs and budget.

If you need a knife steel with exceptional wear resistance, edge retention, and corrosion resistance, then the M390 may be worth the investment.

Are M390 And S45VN Knives The Same?

No, M390 and S45VN steels are not the same. While they may both be high-quality steel options, they differ in several key areas. For example, M390 steel is known for its excellent corrosion resistance, while S45VN steel is known for its balanced properties.

Additionally, Bohler M390 steel is known for its wear resistance, while S45VN steel is known for its ease of sharpening. Ultimately, the choice between M390 and S45VN will depend on your specific needs and preferences.

Is M390 Better Than S45VN?

In terms of corrosion resistance, wear resistance, and edge retention, M390 is generally considered to be slightly better than S45VN. On the other hand, S45VN is known for better toughness and ease of sharpening.

The choice between M390 and S45VN will depend on your specific needs and preferences. If you prioritize corrosion resistance, wear resistance and edge retention, M390 may be the better choice for you. If you value toughness and ease of sharpening, S45VN may be the better option.

Final thoughts on M390 vs S45VN

In conclusion, CPM S45VN steel blades offer slightly better toughness than M390 steel blades and are easier to sharpen. On the other hand, M390 steel blades have better performance in corrosion resistance and edge retention.

In terms of corrosion resistance, Bohler M390 steel is among the best in all stainless steel, only being outperformed by Vanax, LC200N, and MagnaCut steel.

The main difference between S45VN and M390 steel is that S45VN has a more balanced composition with reduced chromium elements, while M390 was designed to be a high wear-resistant and stainless steel with a high amount of chromium elements.