The Battle of Super Steels: S35VN vs S30V

In the realm of super steels, two names stand tall: S35VN and S30V. These high-performance stainless steels have become popular choices for blades in the knife-making community, but which one reigns supreme? In this highly anticipated battle, we will compare the key characteristics and performance of S35VN and S30V to determine which steel takes the crown.

S35VN is often hailed as an upgraded version of S30V, boasting improved toughness and corrosion resistance while maintaining exceptional edge retention. Developed by Crucible Industries, S35VN incorporates a fine-grained structure and the addition of niobium for enhanced toughness.

On the other hand, S30V, created by knifemaker Chris Reeve and Crucible Industries, has long been revered for its excellent edge retention and toughness. This showdown will delve deep into the metallurgical properties, edge retention, and corrosion resistance of both super steels, providing valuable insights for knife enthusiasts and makers alike.

Whether you are seeking a blade that excels in edge holding or one that can withstand extreme conditions, this comparison will help you make an informed decision. Join us as we embark on an epic clash of super steels to discover the ultimate champion of the knife world: S35VN or S30V.

In this article, we will be taking a closer look at S45VN and S35VN steel, two popular types of knife steels that are often used in most knives. We will be comparing these two steels in terms of composition, toughness, edge retention, corrosion resistance, ease of sharpening, the intention of use, and lastly price.

According to Crucible Industries the maker of these steels, S35VN Steel is actually a variation of S30V steel, while S45VN is a variation of S35VN. Let’s break down all the key differences between these two steels to help you make an informed decision for your next pick. So, let’s get started!

About S35VN Steel

S35VN steel is developed by Crucible Industries, through the Crucible Particle Metallurgy(CPM) process that results in a very homogeneous, high quality steel. S35VN is also referred to as CPM S35VN steel.

S35VN steel is a martensitic stainless steel that was developed as an improvement to the popular S30V steel, with the addition of niobium in its alloy composition.

The addition of Niobium is to improve the toughness of this steel without sacrificing wear resistance.

S35VN stainless steel is known for its excellent balance of toughness, edge retention, corrosion resistance, and wear resistance.

It is often used in the manufacture of pocket knives, kitchen knives, and other cutting tools. Apart from the manufacture of knives, S35VN steel is also used in the manufacture of Valve components, screws, dies, and in the food and chemical industries.

About S45VN Steel

S35VN steel is also developed by Crucible Industries through the Crucible Particle Metallurgy (CPM) process that results in a very homogeneous, high-quality steel.

S45VN steel is a martensitic stainless steel that was developed as an improvement on the popular S35VN steel, with the addition of Nitrogen and more chromium in its alloy composition.

The addition of Nitrogen and more chromium in S45VN steel is intended at improving the corrosion resistance of the steel.

According to research, the addition of Nitrogen to steel composition significantly enhances the corrosion resistance of steel.

The use of Niobium and Nitrogen elements in substitution of some of the Vanadium and Carbon elements in S35VN steel composition creates an optimal combination of edge retention, wear resistance, corrosion resistance, and toughness for S45VN. This makes it an ideal choice for an everyday carry (EDC) knife steel.

The rebalanced composition of S45VN steel enables it to have a volume of 15% carbides which is 1.00% more Carbide volume when compared to S35VN 14% carbide volume.

S35VN vs S45VN: Comparison Table

| Specification | S45VN Steel | S35VN Steel |

|---|---|---|

| Composition | Carbon 1.48% Chromium 16.00% Molybdenum 2.00% Vanadium 3.00% Niobium 0.50% Nitrogen 0.15% |

Carbon 1.40% Chromium 14.00% Molybdenum 2.00% Vanadium 3.00% Niobium 0.50% |

| Rockwell Hardness | 59-61 HRC | 58-61 HRC |

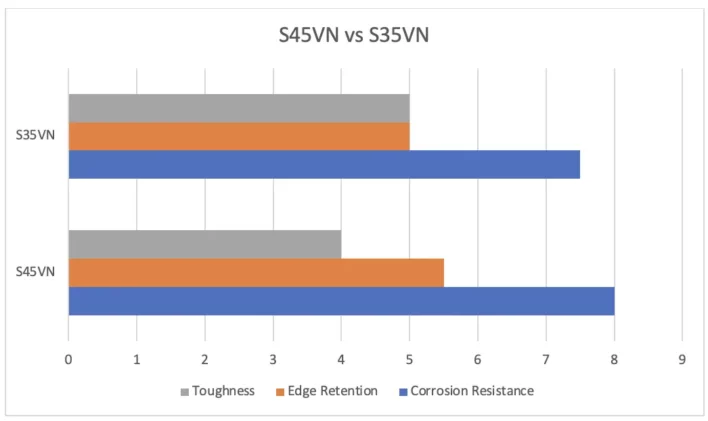

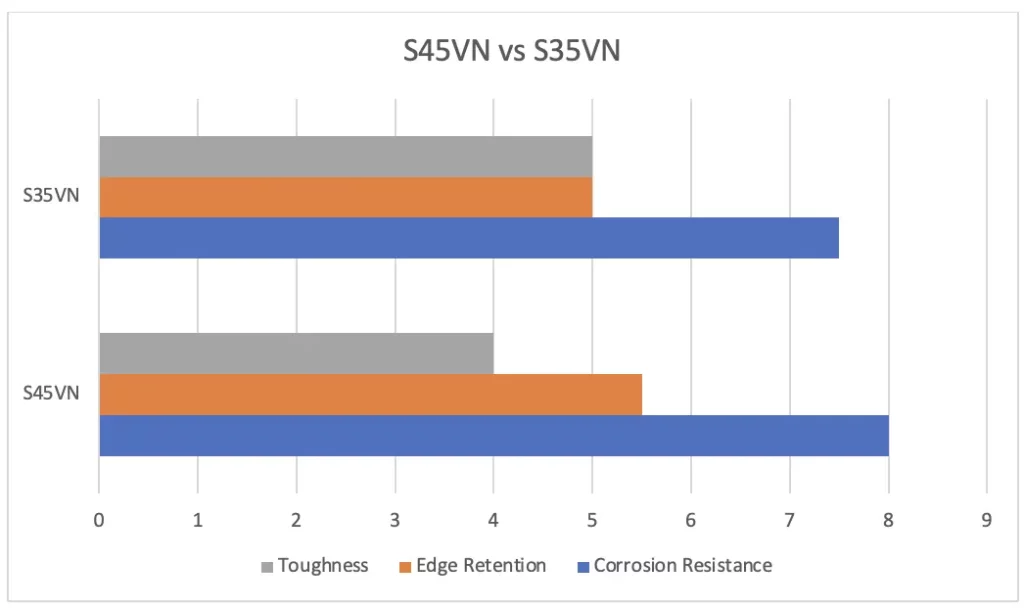

| Edge Retention | 5.5/10 | 5/10 |

| Toughness | 4/10 | 5/10 |

| Corrosion Resistance | 8/10 | 7.5/10 |

| Ease of Sharpening | Average | Averagely Easy |

Toughness

Toughness is a crucial characteristic to consider when choosing a steel for your blade, it’s the ability of the steel to resist chipping, breaking, and deforming under impact or stress.

A tough knife steel will be able to withstand repeated heavy use and impact without failing, making it an ideal choice for applications where durability is a concern.

S35VN and S45VN steel both have good toughness, making them well-suited for a wide range of applications. In terms of how they compare to each other, according to Crucible Industries S35VN is slightly tougher than S45VN.

The slightly reduced toughness of S45VN steel compared to S35VN can be attributed to the increase in the total volume of Carbide content in S45VN steel. While carbides improve the wear resistance of the steel, they also lower the toughness as they are hard and brittle.

For knifemakers, the toughness of these steels is also highly dependent on the heat treatment applied. Crucible Industries lists the best suitable temperature to achieve a balance between hardness and toughness in the respective data sheets.

When compared to other stainless steels offering the same level of Rockwell Hardness, S35VN and S45VN are both highly regarded for their toughness.

However, in real-world use both steels are averagely resistant to chipping and breaking, and thus should not be subjected to heavy impact lest you break or chip the blade.

If toughness is a limiting factor, you should consider other steels in the markets offering a better level of toughness.

Edge Retention

Edge retention is the ability of steel to hold a sharp edge for a long time without dulling even after frequent cuts and slices, it is the most considered characteristic when choosing a knife for most buyers.

Both S35VN and S45VN steels have excellent edge retention making them suited for a wider range of knives. In terms of how they match against each other, S45VN steel has slightly improved edge retention compared to S35VN steel.

The improved edge retention of S45VN over S35VN is attributed to the increase in the carbide volume present in the composition of S45VN. S45VN steel has about 1% more chromium carbide volume when compared to S35VN steel.

According to CATRA Testing relative to 440C steel, CPM S45VN steel has an increase of about 43% edge retention over 440C steel and about 3% over S35VN.

Independent research from Dr.Larrin Thomas, also shows that S45VN has a slight improvement in edge retention over S35VN steel due to the amount of Carbide content present in its composition.

Corrosion Resistance

Corrosion resistance is the ability of steel to resist rust when subjected to corrosive environments. It is important to consider the corrosion resistance of steel if the knife is going to be used in a humid or outdoor environment.

Both S35VN and S45VN are stainless steel with 14% chromium content and 16% chromium content respectively; they have excellent corrosion resistance.

In terms of how they compare to each other, S45VN steel is an improvement of S35VN steel and it generally offers better corrosion resistance compared to S35VN steel.

The improved corrosion resistance of S45VN steel is due to the increased chromium content and addition of Nitrogen in the steel alloy composition.

The addition of 0.15% Nitrogen and an increase in Chromium content, enables the formation of more chromium carbides while also leaving some chromium in the matrix for greater corrosion resistance.

Nitrogen addition in steel not only increases the corrosion resistance but also the Rockwell Hardness of steel enabling better wear resistance.

Other Nitrogen alloyed steels like BD1N, LC200N, and Vanax, offer better corrosion resistance than S45VN steel.

Ease Of Sharpening

Ease of sharpening is also another factor to consider when choosing a steel for your knife especially if you will be using it in environments that require frequent sharpening.

The CPM process ensures the production of homogenous high-quality steel that produces excellent wear resistance and is also easy to sharpen.

Both S35VN and S45VN are made through the CPM process which enables better grindability compared to other conventional steels.

S35VN steel might be easier to sharpen than S45VN steel due to slightly lower carbides in its composition. The Increased chromium carbides of S45VN may slightly limit the ease of sharpening.

It is worth noting that despite containing hard Niobium and vanadium carbides, CPM S35VN and S45VN are relatively easy to grind and sharpen than the popular CPM S30V steel.

Intention Of Use

S35VN and S45VN steel are both highly versatile steels that are suited for a wide range of knives due to their optimal balance in wear resistance, edge retention, toughness, and corrosion resistance.

S45VN steel is an ideal choice for EDC knives, due to its improvement in corrosion resistance while S35VN is an Ideal choice for knives that require a bit of toughness as it offers overall better toughness than both S30V steel and S35VN steel.

Price

When it comes to the pricing of S35VN and S45VN knives, various factors play into consideration. These factors include demand for the steel, availability of the steel, and type/design of the knife.

In terms of availability, both S35VN and S45VN steel are available with most manufacturers, however, S45VN steel can be out of stock sometimes as it is a fairly new steel of the two steels.

S45VN steel knives tend to be more expensive than S35VN steel knives, due to the improved wear resistance, and corrosion resistance. Also, fact that S45VN steel is an overall improvement of S35VN steel, the price will tend to be a bit higher.

Is S45VN Better Than S35VN?

S45VN steel is better than S35VN steel in corrosion resistance and wear resistance, but is generally considered to be less tough than S35VN steel. Both steels are highly regarded for their balanced performance and are suitable for a wide range of knives.

Conclusion on S45VN vs S35VN

In conclusion, S35VN and S45VN are both high-quality stainless steels produced by Crucible that are well-suited for a wide range of knives. S35VN steel is an iteration of S30V steel with a focus on increased toughness.

On the other hand, S45VN steel is an iteration of S35VN with a focus on increased corrosion resistance and wear resistance.

See all of these knives on sale at Amazon

S45VN steel is an Ideal choice for any Everyday carry knife while S35VN is a good choice for an EDC or any knife that will be put in areas where it demands a little more toughness. Are you interested in making your own knife from S35VN steel? See our recent contribution all about the accessories needed to make knives.