What is D2 Steel?

D2 steel is a die type of steel, evidenced by the letter D in its name. D2 is an air-hardening, high carbon steel, high chromium steel and has one of the highest levels of carbon among tool steel alloys.

Is D2 Steel Stainless?

However, D2 steel is not categorized as stainless steel because it has a chromium composition of 11.5 to 12%, which does not meet the 13% chromium content to make it stainless. Because of this, D2 tool steel is referred to as semi-stainless tool steel.

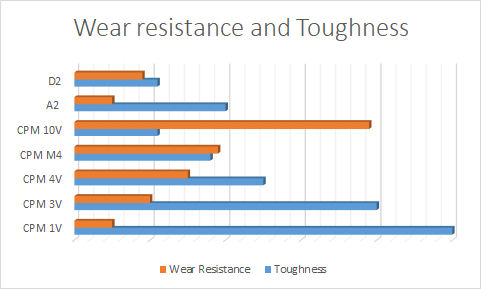

Wear resistance and Toughness of D2 steel vs other steels

D2 Steel Edge Retention

As always, steel with high hardness makes blades with good edge retention, which is true with D2 tool steel. The edge retention of D2 is better than that of 154CM, grade 440C and it is similar to that of CPM 3V steel but significantly worse than that of S35VN, S30V, and M390 steels.

The high carbon levels in its composition make this possible. If you are on the market for a knife that will not require frequent sharpening, look into the options made from AISI D2 steel.

D2 Steel Toughness

You rarely get hardness and toughness from the same steel, and this is the case with D2. Since D2 has high hardness, its toughness is low. The low toughness is attributed to the large carbides that negatively affect its toughness.

While there are other knife steels with better toughness than D2, it offers enough hardness to handle light chopping without breaking. The toughness of D2 knife steel is similar to that of Z-Max steel, 154CM, BD1N, and Bohler N690 steel.

Despite its lower toughness, D2 steel is still used in some combat knives due to its high hardness and edge retention.

However, consider tougher steels like X50CrMoV15 or CPM M4** steel** if you are looking for a knife to handle tough applications like batoning and chopping. Low alloy tool steels like 1084 steel will be better for knives that require higher toughness.

D2 Steel Sharpening

Sharpening D2 steel is a challenging task considering that it is hard steel and high on abrasion and wear resistance. It will take you more effort and time to achieve an ultra-sharp edge with D2, but this is compensated with long edge retention, reducing the frequency of sharpening.

Inexperienced knife sharpeners struggle to get an edge from D2 knives, but it is doable, especially using diamond or ceramic sharpeners on the blade. Whetstones also work well going through the different grits.

D2 Steel Corrosion Resistance

The fact that D2 is not stainless steel discourages many people from buying it because of the assumption that it rusts. To clear the air, let us answer a very common question, does D2 steel blade rust? The honest answer will be yes; it does rust but not as easy as many knife users assume.

Unlike martensitic stainless steel, which is known for its excellent corrosion resistance, D2 steel requires more maintenance to prevent rust. While it does not contain the required chromium levels to make it stainless steel, its 12% chromium content is enough to resist corrosion with good care and maintenance. You cannot keep your D2 knives dirty and wet and expect them not to rust, it requires regular clean-up after use.

Applications of D2 Steel

D2 steel is a versatile tool steel that finds its way into a myriad of applications across different industries, thanks to its exceptional wear resistance, high hardness, and good corrosion resistance. Here are some common uses:

-

Cutting Tools: D2 steel is a favorite for making cutting tools such as knives, scissors, and shears. Its high hardness and wear resistance ensure that these tools maintain their sharpness and effectiveness over prolonged use.

-

Wear Parts: The high wear resistance of D2 steel makes it ideal for manufacturing wear parts like gears, bushings, and bearings. These components benefit from D2’s ability to withstand heavy loads and resist abrasion.

-

High-Temperature Applications: D2 steel’s high heat resistance and ability to maintain hardness at elevated temperatures make it suitable for high-temperature applications such as heat treatment and forging.

-

Aerospace Industry: In the aerospace sector, D2 steel is valued for its high strength, low weight, and good corrosion resistance, making it a reliable material for various components.

Advantages of D2 Steel

D2 steel offers several advantages that make it a popular choice among knife makers and manufacturers:

-

High Hardness: With a Rockwell hardness of 60-62 HRC, D2 steel is ideal for cutting tools and wear parts, providing excellent edge retention and durability.

-

Good Corrosion Resistance: Thanks to its high chromium content, D2 steel exhibits good corrosion resistance, making it suitable for use in harsh environments where other steels might fail.

-

High Wear Resistance: The high carbon content and vanadium alloying in D2 steel contribute to its impressive wear resistance, making it perfect for high-wear applications.

-

Good Edge Retention: D2 steel’s high hardness and wear resistance ensure that knives and cutting tools made from this steel maintain their sharp edges for longer periods, reducing the need for frequent sharpening.

-

Affordable: Compared to other high-end knife steels, D2 steel is relatively affordable, making it an attractive option for both knife makers and consumers looking for quality without breaking the bank.

Limitations of D2 Steel

While D2 steel has many advantages, it also comes with some limitations that need to be considered:

-

Brittle: D2 steel is known for its brittleness, which makes it prone to cracking. This can pose challenges during knife making and other applications where flexibility is required.

-

Difficult to Sharpen: Due to its high hardness, D2 steel can be challenging to sharpen. Maintaining a sharp edge requires more effort and specialized sharpening tools, which can be a drawback for some users.

-

Not Suitable for High-Impact Applications: The brittleness of D2 steel makes it unsuitable for high-impact applications. It tends to crack under heavy loads, limiting its use in scenarios that require high toughness.

-

Not Suitable for Acidic Environments: Despite its good corrosion resistance, D2 steel is not ideal for acidic environments. The high chromium content can make it prone to corrosion when exposed to acidic conditions, necessitating careful maintenance.

By understanding both the strengths and limitations of D2 steel, users can make informed decisions about its suitability for their specific needs.

D2 Steel Comparison

D2 Vs S30V

The major difference between D2 steel and S30V steel is that D2 steel is conventionally produced steel while S30V is powder metallurgy steel. S30V steel is better knife steel than D2 steel as it exhibits a more balanced approach in performance aspects like toughness, corrosion resistance, and edge retention.

A key difference to also note between D2 and CPM S30V steel is that D2 is non-stainless tool steel while S30V steel is stainless steel with excellent corrosion resistance properties.

The fine microstructure and hard vanadium carbides of S30V steel enable it to perform slightly better than D2 in edge retention. The fine microstructure also contributes to the better toughness of the S30V steel blade over the D2 blade steel.

D2 tool steel outperforms S30V steel in wear resistance due to the high amount of carbon in its composition that enables it to attain a higher Rockwell hardness than S30V stainless steel.

CPM D2 Vs D2

CPM-D2 is a powder metallurgical variant of the D2 steel. It is a relatively new steel blade in the market following advancement in steel production by Crucible CPM technology.

CPM D2 steel is more refined and has reduced chromium carbide required in die steels, thus it provides better toughness value than regular D2 steel and responds better to heat treatment.

D2 Steel Equivalent

D2 steel equivalent includes Bohler K110 steel, Cr12Mo1V steel, JIS SKD11 Steel, and 1.2379 steel. Another steel that offers close to similar performance to AISI D2 is M2 steel. For example, 1.4116 steel, commonly used in Swiss Army knives, offers similar corrosion resistance and ease of sharpening as D2 steel.

Also read CPM CruWear steel review, an upgraded version of D2 steel.

Is D2 Knife Steel Good?

The high wear resistance and edge retention make D2 steel a perfect choice for knives. You might struggle a bit with sharpening, but D2 knives are quality and affordable options.

It is suitable blade steel for a seasoned knife maker and user alike. Reputable Knifemakers like Bob Dozier have solely built their name in knife blades by utilizing D2 blade steel.

See Also: Niolox Steel Review, An improved D2 steel with added Niobium

- Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

- ALL-IN-ONE KITCHEN SET - 15-piece knife set includes. 8" chef's knife, 8" slicing knife, 7" Santoku knife, 8" serrated bread knife, 5" utility knife, 3.5" paring knife, 6 4.5" serrated steak knives, 1 kitchen shear and hard wood knife block with built-in knife sharpener

- HIGH PERFORMANCE - HUNTER.DUAL kitchen knife set is stain and rust resistant and can be used with high frequency or after long periods of inactivity to fully utilize the life of the knives

- NON-STICK & RUST RESISTANT - With a black coating that prevents oxidation of the steel, the kitchen knife set will last a long time and remain non-stick and rust resistant

- SHARP BLADES & NON-SKID HANDLE - Each of HUNTER.DULA knives is carefully tuned to be the sharpest it can be and wears a built-in sharpener. The ergonomically designed handle provides a comfortable grip and the handle will no longer loosen or fall off

- DISHWASHER SAFE - The knife set can be washed in the dishwasher, easy and quick to operate, and dry the knife set after cleaning for easy storage, not taking up space

- High-Quality Stainless Steel Blades

- Ergonomic Handle for Comfortable Control

- Lifetime Warranty

Conclusion

If you were struggling to decide on whether or not to buy a D2 steel knife, this review should give you the go-ahead. A blade from D2 is a good option compared to other non-stainless steels on the market.

D2 steel is conventionally produced and thus widely available from most tool steel companies, this makes it cheaper and easier to find as compared to powder steel. You can also find D2 as Bohler K110 Steel