Table of Contents

What is S30V Steel?

CPM S30V steel is a powder metallurgy type of stainless steel produced by the US Crucible Industries. S30V steel offers a great balance in terms of toughness, edge retention, and corrosion resistance.

It is often considered premium steel and highly preferred in the making of knives. To note, Crucible Particulate Metallurgy S30V (CPM S30V) and S30V are the same steel.

In recent years, there have been advances to make the best combination of hardest, wear resistance, and corrosion resistance steel, and S30V powder steel is a product of that effort.

If you are in the market for a high-end pocket knife, a folding knife made from premium stainless steel, consider CPM S30V varieties. Blades made from this steel have proven to be corrosion-resistant and effective.

Unlike traditionally rotated steels, S30V martensitic stainless steel is made following powder metallurgy. A process that reduces molten alloys to powder. The grains are then firmly pressed together to produce high-quality powdered steel with exceptional toughness and stability.

CPM S30V Steel Composition

The composition of CPM S30V steel is made up of several alloying elements, each of which plays a specific role in the overall performance of the steel. The main elements present in CPM S30V steel include carbon, chromium, vanadium, and molybdenum.

Carbon is an essential element in steel, and in CPM S30V steel, it is present at a level of 1.45%. Carbon helps to improve the strength and hardness of the steel, as well as its ability to retain a sharp edge.

Chromium is another key element in CPM S30V steel, making up 14% of the composition. Chromium helps to improve the corrosion resistance of the steel, as well as its ability to form a hard, wear-resistant surface.

Vanadium is present at a level of 4% in CPM S30V steel and plays a vital role in the steel’s performance. Vanadium helps to improve the toughness of the steel and promotes the formation of vanadium carbides. These carbides are harder and more effective at providing wear resistance than chromium carbides, making CPM S30V steel a highly durable and long-lasting choice for knife making.

Molybdenum is present at a level of 2% in CPM S30V steel and helps to improve the steel’s overall toughness and wear resistance. It also helps to improve the corrosion resistance of the steel in certain environments.

Overall, the combination of these alloying elements in CPM S30V steel creates a high-performance steel that is highly resistant to wear, corrosion, and abrasion, and offers excellent toughness and edge retention.

CPM S30V Steel Properties

Hardness

Hardness is an important factor to consider when choosing knife steel, as it can significantly impact the performance of the blade. Hardness is typically measured using the Rockwell hardness scale, and the higher the number, the harder the steel.

CPM S30V steel is known for its high level of hardness, and it can achieve a Rockwell hardness of 58 to 61 HRC. However, it is most commonly found at a Rockwell hardness of 61 HRC.

The high level of hardness in CPM S30V steel is achieved through the use of vanadium carbides, which are harder and more effective at providing wear resistance than chromium carbides.

This helps to improve the overall durability and longevity of the blade. The hardness of CPM S30V steel also contributes to its ability to retain a sharp edge, as it is more resistant to dulling and deformation.

However, it is important to note that while a higher level of hardness can improve the performance of a blade, it can also make the steel more difficult to work with and sharpen.

It is important to find a balance between hardness and other properties, such as toughness, to ensure that the blade is suitable for its intended use. Overall, the high level of hardness in CPM S30V steel makes it a strong and durable choice for knives.

Edge retention

Edge retention is a crucial factor to consider when choosing a knife steel, as it determines the ability of the blade to maintain a sharp edge over time.

CPM S30V steel is known for its excellent edge retention and performs better than many other steels in this regard.

In the CATRA (Cutlery & Allied Trades Research Association) test, CPM S30V steel was found to have superior edge retention compared to 154 CM steel, 440C, and many other steels.

There are several factors that contribute to the excellent edge retention of CPM S30V steel. One of the main factors is the high level of hardness of the steel, which helps to prevent dulling and deformation of the blade. The presence of vanadium carbides in the steel also helps to improve its wear resistance, which can prolong the life of the edge.

Additionally, the balanced composition of CPM S30V steel, including the presence of chromium, helps to improve its corrosion resistance, which can prevent the blade from dulling due to rust or other forms of corrosion.

While CPM S30V steel has excellent edge retention, it is important to note that the edge retention of any knife can be affected by various factors, such as the type of materials being cut, the frequency of use, and the method of sharpening.

Proper maintenance, including sharpening and cleaning, can help to extend the life of the edge and ensure that the blade stays sharp for as long as possible.

Overall, CPM S30V steel offers excellent edge retention and is a great choice for those looking for a blade that can maintain a sharp edge for an extended period of time.

Wear resistance

Wear resistance is an important characteristic to consider when choosing a knife, as it determines the ability of the blade to withstand wear and abrasion over time.

CPM S30V steel is known for its excellent wear resistance, and it performs better than most other steels in this regard. However, it is important to note that there are other steels, such as S90V, that have even better wear resistance.

The wear resistance of CPM S30V steel is achieved through the presence of vanadium carbides in the steel’s composition.

These carbides are harder and more effective at providing wear resistance than chromium carbides, which helps to improve the overall durability and longevity of the blade.

Additionally, the balanced composition of CPM S30V steel, including the presence of carbon, chromium, and molybdenum, helps to improve its overall wear resistance in certain environments.

While CPM S30V steel has excellent wear resistance, it is important to note that the wear resistance of any knife can be affected by various factors, such as the type of materials being cut and the frequency of use.

Proper care and maintenance, including sharpening and cleaning the blade, can help to extend the life of the blade and ensure that it stays in top condition for as long as possible. CPM S30V steel offers excellent wear resistance and is a great choice for those looking for a blade that can withstand wear and abrasion over time.

Ease of sharpening

Ease of sharpening is an important factor to consider when choosing a knife steel, as it determines the level of difficulty involved in maintaining the blade’s edge.

CPM S30V steel is generally considered to be a relatively easy steel to sharpen, although it is important to note that the level of difficulty can vary depending on the specific knife and the sharpening method being used.

One of the factors that contributes to the ease of sharpening CPM S30V steel is the presence of vanadium carbides in its composition. These carbides are harder and more effective at providing wear resistance than chromium carbides, which can make the blade more difficult to sharpen.

However, the balanced composition of CPM S30V steel, including the presence of carbon, chromium, and molybdenum, helps to improve its overall grindability and make it easier to sharpen.

Additionally, the CPM manufacturing process used to produce CPM S30V steel results in a very homogeneous, high quality steel with superior dimensional stability and grindability.

This makes the steel easier to work with and sharpen, and can help to reduce the time and effort required to maintain the blade’s edge.

Overall, while CPM S30V steel is generally considered to be an easy steel to sharpen, the level of difficulty can vary depending on the specific knife and sharpening method being used.

The benefits of the CPM manufacturing process, including superior dimensional stability and grindability, can make CPM S30V steel especially easy steel to work with and sharpen.

To get a razor-sharp edge with a knife made from S30V, you will need abrasives with higher hardness than CPM S30V steel itself. Achieving a defined edge will take you some energy and time because it possesses strong wear resistance.

However, to pay for the time-consuming sharpening, it maintains its sharpness for a long time, so you will not need to go through the stress of sharpening now and then.

Toughness

Toughness is an important characteristic to consider when choosing a knife steel, as it determines the ability of the blade to withstand impacts and resist chipping or breaking.

CPM S30V steel is known for its excellent toughness, and it has a transverse toughness that is four times greater than that of 440C or 154CM.

This higher transverse toughness means that CPM S30V steel is much more resistant to chipping and breaking in applications.

In knifemaking, the higher transverse toughness of CPM S30V steel makes it especially good for bigger blades that may be subjected to more stress and impact.

The toughness of the steel also contributes to its overall durability and longevity, as it is less prone to damage or wear over time.

When it comes to toughness, it is important to find a balance between toughness and other properties, such as hardness and edge retention.

A steel that is too tough may not hold a sharp edge as well, while a steel that is too hard may be more prone to chipping or breaking.

CPM S30V steel strikes a good balance between toughness and other properties, making it a versatile and reliable choice for knife-making.

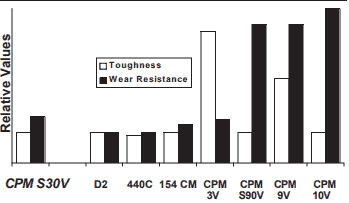

There are tougher steels than CPM-S30V on the market as shown in the graph below from crucible industries. However, it will take you many tough applications with a knife made from S30V steel before it starts to chip, crack or break.

Corrosion resistance

Corrosion resistance is an important factor to consider when choosing a knife steel, as it determines the ability of the blade to resist rust and other forms of corrosion.

CPM S30V steel is known for its excellent corrosion resistance and is equal to or better than 440C in various environments.

This means that it is highly resistant to corrosion and can withstand exposure to moisture and other corrosive elements without losing its structural integrity or performance.

The corrosion resistance of CPM S30V stainless steel is achieved through the presence of chromium in the steel’s composition.

Chromium helps to form a protective layer on the surface of the blade, which prevents the steel from reacting with the environment and prevents rust and other forms of corrosion from forming.

Additionally, the balanced composition of CPM S30V steel, including the presence of vanadium and molybdenum, helps to improve its overall corrosion resistance in certain environments.

While CPM S30V steel has excellent corrosion resistance, it is important to note that the corrosion resistance of any knife can be affected by various factors, such as the environment in which it is used and the level of maintenance it receives.

Proper care and maintenance, including cleaning and drying the blade after use, can help to extend the life of the blade and ensure that it stays rust-free for as long as possible.

Overall, CPM S30V steel offers excellent corrosion resistance and is a great choice for those looking for a blade that can withstand exposure to corrosive elements.

Does S30V steel rust?

S30V steel contains 14% of Chromium, which gives it great corrosion resistance, S30V steel does not rust easily. However, stainless steel is at risk of corrosion if neglected and exposed to corrosion agents. Therefore, if you invest in S30V knives, make sure to wipe them dry after use, and they will remain rust-free for as long as you have them.

Is S30V good knife steel?

Looking at the properties of S30V steel, we can confidently say that S30V steel is excellent steel suitable for knives. Its exceptional hardness, wear resistance, corrosion resistance, and decent toughness make it a good choice for knife makers. You will find popular Spyderco knives and buck knife companies utilizing S30V.

What steel is better than S30V?

With advancements in steel technology, several steels have adopted powder metallurgy production process with more refined alloy compositions beating S30V steel in properties like edge retention, corrosion resistance, and toughness.

It is difficult to find steels that will beat S30V in all performance aspects. However, MagnaCut steel, M390 steel, 20CV steel, S35VN, and S45VN are closely related and may offer better performance than S30V steel when properly heat treated.

CPM S30V steel comparison

440C vs S30V

According to Crucible Industries, the main difference between S30V steel and 440C steel is that S30V steel offers more toughness as compared to 440C and has better corrosion resistance. The transverse toughness of the CPM-S30V stainless steel is four times higher than that of the 440C blade making it a better choice for bigger blades.

S30V steel also offers better edge retention compared to 440C. This is due to the crucible particle metallurgy production process of S30V steel. S30V is generally considered to be better than 440C steel choice due to its superior edge retention and corrosion resistance. It is a high-performance alloy that is specifically designed for use in knives

S30V vs S35VN

The main difference is that the S35VN steel blade contains a finer grade, it is easier to machine and polish than S30V. S35VN is also a bit tougher and would be preferred for a fixed blade by a knife maker.

Both S30V steel and S35VN steel are high-quality blade materials and Both attribute their invention to Chris Reeve and Crucible industries, hence sharing almost similar chemical composition. Both also offer almost similar edge retention.

154CM vs S30V

The main difference between S30V and 154CM is that S30V is powder metallurgy-produced steel while 154CM steel is conventionally produced. CPM S30V steel is better steel than 154CM steel in performance, as it was developed by altering and improving the chemical composition of 154CM steel.

CPM-S30V steel production process results in a more fine-grained structure which offers better edge retention, toughness, and corrosion resistance compared to 154CM steel.

The difference in performance between S30V steel and 154CM steel is not that massive in terms of toughness and corrosion resistance. The most notable difference is in edge retention which is due to the presence of much more Vanadium carbides in the S30V alloy composition.

Sharpening 154CM steel will be much easier as compared to sharpening S30V steel. S30V is harder to sharpen when compared to 154CM due to its improved wear resistance brought about by a higher percentage of Vanadium Carbides.

Both S30V and 154CM are stainless steel, however, the corrosion resistance of S30V steel is improved over 154CM steel due to the addition of molybdenum and nitrogen in its alloy composition.

The toughness of S30V steel is slightly better than that of 154CM steel due to the presence of finer carbides compared to the larger carbides present in 154CM steel.

See Also: S45VN steel review, an update to S35VN and S30V steel

Conclusion

If you have been looking for a confirmation to buy an S30V knife, the review above should give you a confident go-ahead. S30V Stainless Steel is among the best if not the best Knife Steel.

Most knife manufacturers use this steel to make custom knives geared toward different uses due to its excellent toughness, edge retention, and hardness. You will be pleased with the strength and effectiveness that come with your new purchase.