Table of Contents

S90V and M390 are premium steels, but M390 makes better high-end knives because it wins in toughness, corrosion resistance, and ease of sharpening. However, you must consider your knife needs when choosing between S90V and M390 knives.

In this article, we will look at the properties of S90V steel and M390 steel and their pros and cons to help you choose between S90V and M390 knives.

Are S90V and M390 Knives the Same?

Considering that both S90V and M390 are premium steel, you might wonder if knives made from them are the same. The characteristics of high-end knives can be very similar, which can be confusing to newbie knife users.

S90V and M390 knives are not the same. The characteristics of the blades differ in terms of edge retention, toughness, corrosion resistance, and ease of sharpening. They can be used in the knife and industrial industries for the same functions, but the performance of the products is different.

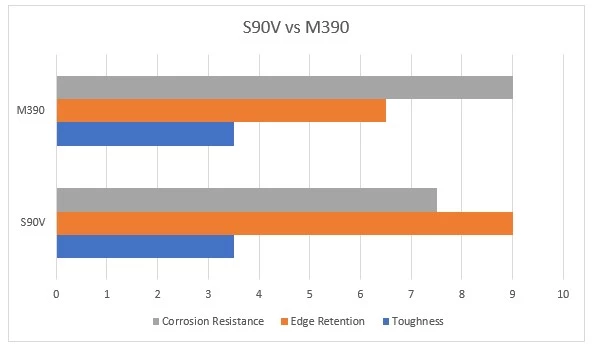

| S90V | M390 | |

|---|---|---|

| Edge retention | 9/10 | 6.5/10 |

| Toughness | 3.5/10 | 3.5/10 |

| Corrosion resistance | 7.5/10 | 9/10 |

To help you differentiate between the two, let us look at the characteristics of each steel in depth. The pros and cons of each will you choose between S90V and M390 knives.

S90V Knife Characteristics

CPM S90V is premium steel manufactured by US-based Crucible Industries following the CPM (Particle Metallurgy) process. It is categorized among the top super steels on the market today because it contains high amounts of Carbon, Chromium, and Vanadium in its composition. The blend of these elements results in excellent edge retention, good corrosion resistance, and toughness.

S90V was initially introduced on the market as CPM 420V, a tool used to make screws, bearings, and slitters. Over the years, crucible industries have continued developing it to the modern CPM S90V used to make high-end knives for different applications.

Being premium steel, S90V is very expensive. Its high pricing is associated with the fact that it is very difficult to work on. It requires sophisticated tools and takes the knife makers more time and energy to craft the final product.

Pros

- Excellent edge retention

- Good corrosion resistance

- Good balance

Cons

- Very difficult to sharpen

- Average toughness

- Expensive

M390 knife Characteristics

M390 is super steel by Bohler-Uddeholm, produced following third-generation PM (powder metallurgy). It contains high chromium and vanadium carbides and, as a result, offers extreme edge retention wear resistance, and corrosion resistance.

Moreover, M390 features a fine-grain microstructure that makes it easy to finish, giving the blades good looks.

Because of its excellent wear resistance and high toughness, M390 is categorized as tool steel. It is used in the industrial market to make screws, barrels, and other tools for hard use because it can absorb mechanical shocks and pressure without breaking or chipping.

It is also used in the knife industry to make high-end small knives. However, knives made from this blade steel are costly.

Unlike most super steels, M390 is easy to sharpen because it contains 20 % chromium which gives it higher chromium carbides softer than Vanadium carbides.

Pros

- Extreme edge retention

- Extreme corrosion resistance

- Easy to sharpen

Cons

- Expensive

- Average toughness

- Limited edition knives because the steel is expensive.

How To Choose Between The S90V And The M390

To choose between S90V knives and M390 knives, you should consider the characteristics of each steel and how you intend to use them. Look at your lifestyle, the commitment to knife care and maintenance, and your budget to decide.

| S90V | M390 | |

|---|---|---|

| Edge retention | 9/10 | 6.5/10 |

| Toughness | 3.5/10 | 3.5/10 |

| Corrosion resistance | 7.5/10 | 9/10 |

Intention For Knife Usage

You must consider your knife needs to choose between S90V and M390 knives. They are both used to make high-end knives but keep in mind that S90V is harder to sharpen and does not offer the best toughness. Therefore, you should have the right knife sharpening skills and not use them for very challenging applications.

Both S90V and M390 are considered premium steel. They offer great balance in toughness, wear resistance, edge retention, and corrosion resistance.

On the other hand, M390 shines in edge retention, toughness, and corrosion resistance. The blades are durable even when used in challenging applications and corrosive environments.

Price

S90V and M390 are premium steels used to make high-end premium knives. However, M390 is more expensive, and the knives are manufactured in limited amounts. Purchasing S90V or M390 knives is only ideal if spending money is not an issue.

What Makes a Good Quality Knife?

The quality of a knife is determined by the characteristics of the steel used to make the blade and the quality of the handle. Seasoned knife users can quickly identify a high-quality knife from the looks, but the specific properties of the steel are the perfect identifier of a quality knife.

A good quality knife should be easy to sharpen, attain a razor-sharp edge, hold the edge for a long time, be durable and strong to withstand challenging applications, and have a high-quality handle.

Depending on your cutting needs, you need a knife that cuts through ingredients or any other material precisely and without the fear that it might break or crack. Moreover, the handle should be slip free to prevent accidents.

Final Thoughts

Both S90V and M390 are considered premium steel. They offer great balance in toughness, wear resistance, edge retention, and corrosion resistance. M390 steel offers better toughness, corrosion resistance, and ease of sharpening. Both M390 and S90V offer an equal level of edge retention.