Table of Contents

20CV steel is a superior steel to S30V steel for a variety of reasons. In this article, we will be comparing 20CV steel and S30V steel in terms of composition, toughness, edge retention, corrosion resistance, ease of sharpening, and price.

20CV steel and S30V steel are two popular CPM stainless steels widely used in the manufacture of all kinds of knives and other cutting tools.

By the end of the article, you should have a better understanding of 20CV and S30V and make an informed decision on which steel is the right choice for you.

About 20CV Steel

20CV steel is a martensitic stainless steel produced by crucible industries following the Crucible particle metallurgy process, it is uniquely made with high Vanadium, Chromium in addition to Tungsten content.

The Crucible CPM process ensures that 20CV steel has finer, uniform carbide distribution thus improving the toughness and grindability of the steel.

CPM 20CV stainless steel is known for its composition which comprises a high volume of vanadium carbides giving it exceptional wear resistance. 20CV is thus ideal for use in knives that will be subjected to extreme wear and abrasion.

The high chromium content gives it good corrosion resistance better than 440C steel, making it suitable for use in a variety of humid environments.

20CV steel is used in the manufacture of knives, Long-Wearing Specialty Cutlery, Pelletizing Equipment, and in the food and chemical processing industry equipment.

It is worth noting that 20CV steel was originally produced as a copy of Bohler M390 steel by Timken and was originally called Duratech 20CV steel before the company was sold.

About S30V Steel

S30V steel is a popular choice for use in most types of knives. It was developed by Crucible Industries in the early 2000s and has since become a go-to steel for lots of knife makers and enthusiasts.

S30V steel is a martensitic stainless steel, made following the Crucible Particle Metallurgy Process (CPM) which produces highly homogenous steel with a balanced combination of toughness, edge retention, and corrosion resistance.

The CPM process in S30V was designed to favor the formation of vanadium carbides. Vanadium carbides are harder and have more wear resistance than chromium carbides which are often used in most stainless steels.

The result is highly efficiently balanced steel that is tough, highly resistant to wear and corrosion, making it ideal for use in most knives.

Apart from the manufacture of knives CPM S30V steel is also used in the manufacture of Pelletizing equipment, Valve components, screws, dies, and in the food and chemical industries.

Comparison Table: 20CV vs S30V

| Specification | 20CV Steel | S30V Steel |

|---|---|---|

| Composition | Carbon 1.9% Chromium 20.00% Molybdenum 2.00% Vanadium 4.00% Tungsten 0.6% |

Carbon 1.45% Chromium 14.00% Molybdenum 2.00% Vanadium 4.00% |

| Rockwell Hardness | 58-61 HRC | 58-61 HRC |

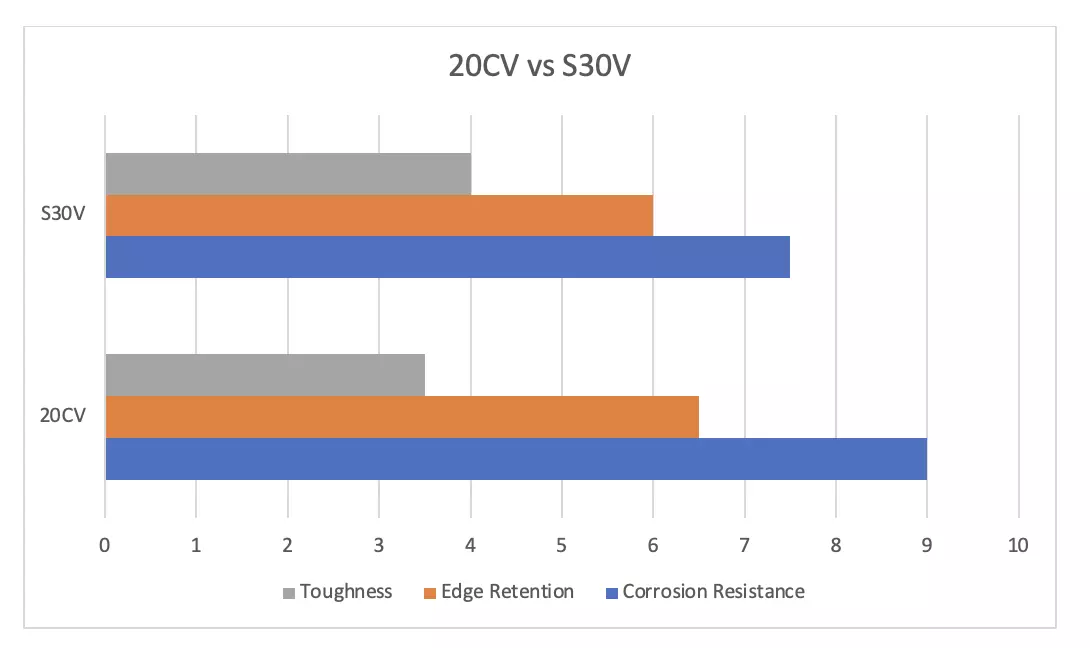

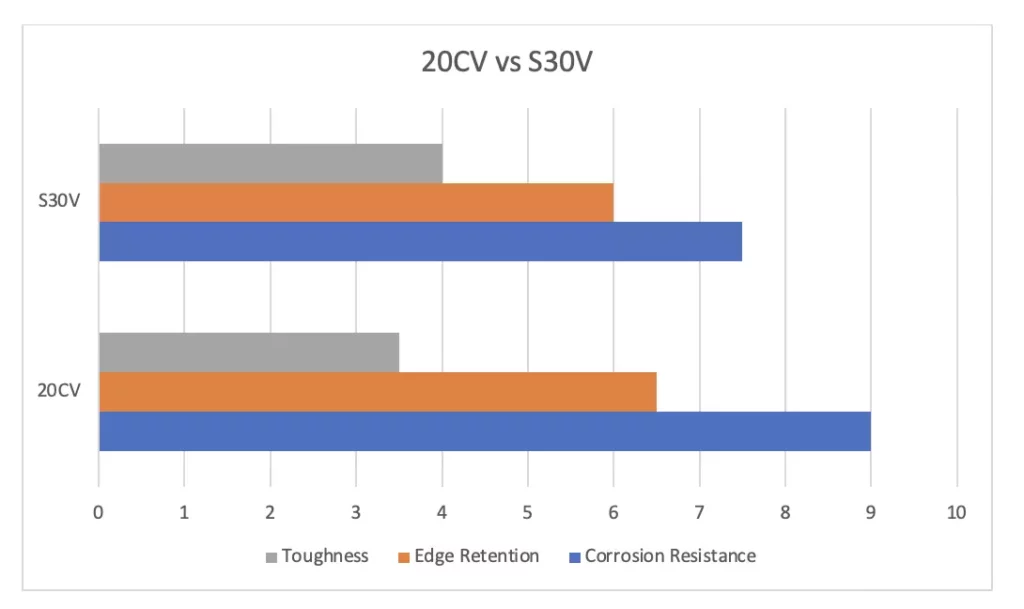

| Edge Retention | 6.5/10 | 5/10 |

| Toughness | 3.5/10 | 5/10 |

| Corrosion Resistance | 9/10 | 7.5/10 |

| Ease of Sharpening | Hard | Average |

Toughness

Toughness is among the most important factors to consider when choosing a knife. It refers to a steel’s ability to resist chipping or breaking when subjected to stress or impact.

Both 20CV and S30V steel offer average toughness and are not the best, however, S30V has slightly better toughness than 20CV steel.

S30V steel improved toughness is due to its balanced composition of primary elements like Carbon, Chromium, and vanadium (at least 4%), which gives it a more finely-grained microstructure.

This makes S30V steel a better choice for use in applications where the blade may be subjected to slightly heavy use or impact when compared to 20CV steel.

CPM 20CV steel may not be quite as resistant to chipping or breaking as S30V. However, it still performs well in most applications and is a good choice for those who won’t use their knives for tough applications but favor steel with the excellent edge retention and wear resistance.

Edge Retention

One of the most important factors to consider when choosing a steel for a knife blade is its edge retention. Edge retention is how well the blade edge maintains its sharpness over repeated use. Both 20CV and S30V steels are known for their excellent edge retention, but 20CV steel offers better edge retention.

According to Crucible Industries, both 20CV and S30V steel can achieve a Rockwell Hardness of 58-61, however, 20CV steel has a higher volume of Vanadium Carbides. This means that 20CV has harder carbides and is able to maintain a sharper edge for a longer period than S30V steel.

According to CATRA testing data provided by Crucible Industries, 20CV steel offers about 15% better edge retention than S30V steel. These results have been confirmed by other independent tests from other knife experts like Dr. Larrin Thomas.

The vanadium carbides in both S30V and 20CV are known to provide excellent wear resistance and better edge retention as they are extremely hard. This is what makes these steels attractive for high-speed applications where wear resistance is favored.

Corrosion Resistance

Another factor to also consider when choosing a knife steel is its corrosion resistance, or how well it resists rust and other forms of corrosion when subjected to humid or corrosive environments. In corrosion resistance, 20CV steel is the clear winner over S30V steel.

20CV is a high carbon, high chromium stainless steel, it has a higher level of chromium (at 20%) compared to S30V steel with 14% chromium content. This gives 20CV steel excellent corrosion resistance, making it a great choice for use in humid or corrosive environments.

The 20% chromium content enables the formation of chromium carbide while leaving some chromium elements for corrosion resistance.

It’s worth noting that Chromium is not the only element responsible for corrosion resistance, other elements like molybdenum also contribute to the corrosion resistance of steel. If you are to choose between 20CV and S30V steel in terms of corrosion resistance 20CV is a clear choice.

Ease of Sharpening

When comparing the ease of sharpening between these two steels, S30V steel is easier to sharpen than 20CV steel. S30V steel is easier to sharpen as it has a slightly softer, more ductile structure, which allows it to be more easily grind and honed to a finer edge.

20CV steel is harder to sharpen than S30V steel due to its incredible wear resistance brought about by the higher volumes of carbides. 20CV contains more chromium and vanadium carbides which are hard and tough to grind.

Both 20CV and S30V can be sharpened by regular sharpening stones which are created from aluminum oxide. However, these steels contain Vanadium carbides which are harder than aluminum oxide thus it will take a bit of time and effort.

Apart from dealing with material removal when sharpening these two blade steels, deburring can also be a tougher task and thus it is recommended to use Diamond and CBN sharpening stones to make it easier.

Intention of use

The intention of use is also another important factor to consider when choosing between 20CV and S30V blade steels. CPM 20CV steel is most often used in high-end knives that require a sharp and durable edge.

It is well-suited for knives that are required to be highly corrosion-resistant and have precision cutting tasks. It is a popular choice among, knife enthusiasts, medics, divers, and other professionals who require a sharp and precise blade.

In contrast, S30V steel may be more suitable for smaller pocket knives, kitchen knives, and EDC in general. S30V steel has good edge retention and is the easier of the two to sharpen when the need arises, it is also a bit tougher.

Price

Generally, 20CV steel knives are pricier than S30V steel knives, and this is attributed to their excellent wear resistance, edge retention, and corrosion resistance.

CPM 20CV is considered more premium steel than CPM S30V steel. It is an exact copy of M390 steel in terms of corrosion resistance, edge retention, and toughness.

Despite S30V steel being cheaper, it is probably the best choice of the two for normal use as it offers balanced performance in terms of edge retention, corrosion resistance, and toughness.

Related Reading: CPM 154 Vs. CPM 20CV Knives: Which Is Better?

Conclusion on 20CV vs S30V

In conclusion, 20CV steel is better than S30V in aspects of edge retention, wear resistance, and corrosion resistance. It is also more expensive than S30V steel and is considered more premium steel.

S30V steel is an excellent steel for most EDCs as it offers a better balance of edge retention, corrosion resistance, and toughness. It is also cheaper than 20CV steel and is commonly available in most knives.

It is worth noting that 20CV steel performance is similar to M390 steel and CTS 204P steel. S30V steel on the other hand is on par with the likes of its predecessors S35VN and S45VN.