How Good Is 4Cr14 Steel?

4Cr14 is popular in the knife-making industry and is mainly used to make folding, tactical, and kitchen knives. Knifemakers like this steel because it offers

4Cr14 is popular in the knife-making industry and is mainly used to make folding, tactical, and kitchen knives. Knifemakers like this steel because it offers

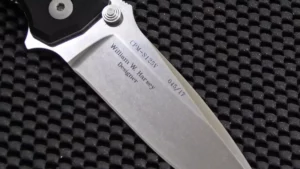

With proper heat treatment, CPM D2 is easy to work with and forms blades that remain sharp even when used daily for tough applications. The

CPM CruWear steel is an air-hardening tool steel produced by Crucible Industries. The air quenching process gives it excellent wear resistance and toughness, making it

It is also important to note that Crucible industries manufacture this steel following the Crucible Particle Metallurgy process. This production process stands out among other

What does this mean for knife users? Blades made from this steel offer excellent wear resistance, edge retention and are consequently difficult to sharpen. Although

10Cr15CoMoV stainless steel is used in the knife industry to make highly polished thin blades with excellent edge retention perfect for slicing. 10Cr15CoMoV Steel Composition

Cobalt boosts the hardness of CPM Rex 45 even at red heat temperature treatments. Because of the high hardness, this steel offers great wear resistance

CPM SPY27, like other steel, is made by combining alloys including Vanadium, niobium, Cobalt, nitrogen, and molybdenum. The composition, added Cobalt, and the CPM manufacturing

Because of its properties, N695 is used in the knife-making industry to make quality knife blades for camping, survival, hunting, and hiking knives. It is