Table of Contents

What is CPM 10V Steel?

CPM 10V steel is high-performance tool steel produced following the Crucible Particle Metallurgy process. It has carbon and vanadium as the main components, which give it excellent wear resistance and toughness.

CPM 10V is strong and durable steel with excellent wear resistance. It can be used in place of other carbide steels to make cold works tooling, which makes it perfect for many tough applications!

CPM 10V tool steel is an alias AISI A11 tool steel or PM A11. Because of its properties, 10V steel is used in several industries to make knife blades, punches and dies, cold forming tools, woodworking tools, wear parts, industrial knives, and tools in the plastic industry.

CPM 10V Steel composition

- Carbon C 2.45%: Increases the edge retention, hardness and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

- Chromium Cr 5.25%: Formation of Chromium carbide Increases hardness, tensile strength and corrosion resistance of the blade.

- Molybdenum Mo 1.30%: It improves machinability and hardness.

- Vanadium V 9.75%: Increase wear resistance and toughness, it also improves corrosion resistance.

Properties of CPM 10V

CPM 10V Steel Hardness

CPM 10V steel has a hardness of 60HRC as per the Rockwell hardness scale, but the hardness differs with the heat treatment used and it can get to high hardness of up to 64HRC. This steel can be hardened by, salt, atmosphere, and vacuum each achieving different results but it requires preheating before high heating.

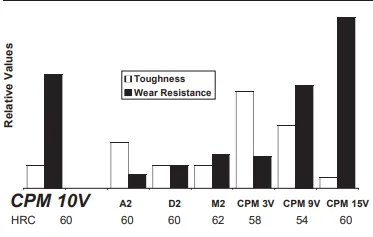

CPM 10V Steel Toughness

One of the areas of excellence for CPM 10V steel is its toughness. It offers better toughness than high-end stainless steel like S30V and CPM 154. The difference in toughness comes in because it is made following the CPM process, which gives it finer carbides.

What’s more, it can maintain excellent toughness even with high hardness, CPM 10V steel thus offers an alternative for most steels that are not able to maintain high toughness with high hardness.

CPM 10V Steel Wear resistance

CPM 10V offers excellent wear resistance, because of the high amounts of vanadium and vanadium carbides. Wear resistance is one of the properties that make this steel stand out among many in the market.

Because of this property, CPM 10V is used as tool steel to make machinery wear parts because it is resistant to damage from wear caused by high temperatures or corrosion.

What’s more, if you are in the market looking for knives that can withstand tough and challenging applications, look into the varieties of CPM 10V knives.

CPM 10V Steel Edge retention

Edge retention is the measure of how long a blade stays sharp with daily or continuous usage. CPM 10V offers excellent edge retention, thanks to the high hardness and wear resistance. If you buy knives with blades from this steel, there is no more sharpening after a few hours of using it.

The fact that it is used as tool steel should tell you how good it is at retaining sharpness. CPM 10V can maintain excellent sharpness even when used in tough applications like batoning, it thus makes a very good camp knife. 10V sharpness can be bettered by a few steels like Maxamet.

CPM 10V Steel Corrosion resistance

One of the downsides of CPM 10V steel is that it is poor in corrosion resistance. It contains low amounts of chromium that does not reach the required limit to make it stainless steel. If you are looking for knives to use in corrosive or wet environments, avoid the varieties of CPM 10V.

However, if you are into its other properties like wear resistance and toughness, you can fight corrosion and stains through proper care and maintenance. Make sure to wash and dry the knives after use. You can also apply a coat of oil on the blade for storage to keep oxidization away.

Note that most tool steels including D2 steel and Sleipner steel all suffer from poor corrosion resistance.

If you are looking for a knife with excellent corrosion resistance look into knife varieties that contain high chromium and or nitrogen elements. Steels like LC200N, S45VN, and CTS BD1N will never disappoint.

Sharpening CPM 10V Steel

Sharpening CPM 10V steel is challenging because of the high wear resistance brought about by the vanadium carbides that are harder than most abrasive materials. You will probably need a diamond sharpening tool to sharpen 10V.

Beginners find it hard to get a sharp edge with 10V steel. The good news is, it retains a sharp edge for long, and therefore, you don’t have to sharpen it frequently.

CPM 10V steel equivalent and CPM 10V comparison

CPM 10V vs K390

Both 10V and K390 offer almost the same level of hardness despite their composition being completely different. K390 steel is known for its outstanding toughness and that remains true even when held up against CPM10V steel. 10V steel beats K390 on edge retention by a small margin but they both offer poor corrosion resistance.

Honestly, it is tough to find steel with properties like that of 10V, K390 performance comes really close to it hence can be considered the best CPM 10V steel equivalent. If by any chance you are given unlabeled knives with both k390 and 10V, it will be hard to know the difference.

Maxamet steel is also another steel that might be considered 10V steel equivalent but it mostly outperforms it and hence K390 is the best bet.

CPM 10V vs S30V

10V steel is harder than S30V and provides better wear resistance, toughness, and edge retention. The high amount of vanadium carbide gives 10V better performance in edge retention and would still cut even when a bit blunt as the vanadium carbide would grab on the material being cut. S30V offers better corrosion resistance but both are difficult to sharpen.

CPM 10V VS S110v

S110V is a high chromium stainless steel while 10V is not stainless hence S110V beats 10V in corrosion resistance. Both 10V and S110V are high performance steel when it comes to edge retention and toughness, more recently 10V production knives have been outperforming S110V in edge retention slightly. Either of the steel will give you outstanding edge retention.

Sharpening both steels will require time and experience to get them super sharp, they are not easy to sharpen due to their high wear resistance.

CPM 10V vs D2 Steel

CPM 10V has vanadium carbides that make it way harder than D2, it excels D2 wear resistance by four times. It thus offers better edge retention and wear resistance. On the other hand, D2 steel provides better corrosion resistance and is a bit easier to sharpen. D2 is also more popular in knife making than 10V due to its availability and easy, forgiving heat treat but 10V is better steel any day.

CPM 10V vs 154CM

CPM 10V offers better wear resistance and edge retention than 154CM. Both steels have similar toughness. On the other hand, 154CM shines in corrosion resistance because it is stainless steel; it contains high amounts of Chromium in its element than 10V. 154CM is easier to sharpen and affordable.

Is CPM 10V good knife steel?

Yes! CPM 10V is great knife steel because of its high hardness, edge retention, and easy machinability. It can only be bettered by a countable number of steels when it comes to edge retention and toughness. However, it has poor corrosion resistance therefore it might not work for you if you are looking for a knife to use in wet and humid conditions.