What is N695 Steel?

Because of its properties, N695 is used in the knife-making industry to make quality knife blades for camping, survival, hunting, and hiking knives. It is also used in other industries to make surgical equipment, fasteners and nuts, valve seats, cold forming, and chisels.

Besides its properties, knife makers are attracted to N695 steel because it is affordable and easy to work with. This translates to low production costs, and therefore, the customers get high-quality knives at an affordable cost.

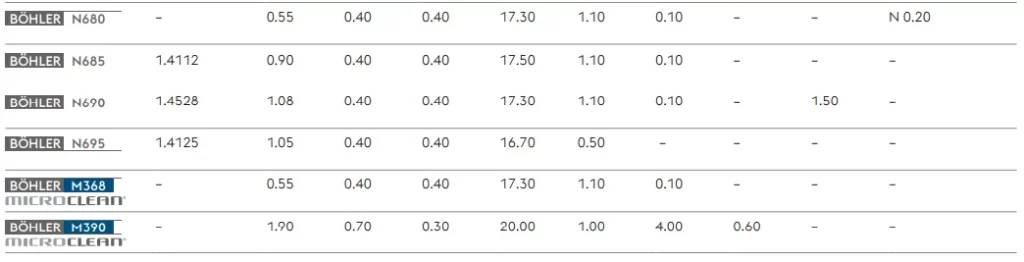

N695 Steel Composition

· Carbon C 1.05%: Increases edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

· Chromium Cr 16.70%: Formation of Chromium carbides. Increases the blade’s hardness, tensile strength, and corrosion resistance.

· Molybdenum Mo 0.50%: It improves machinability and hardness.

· Manganese Mn 0.40%: improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

· Silicon Si 0.40%: Increases strength and heat resistance.

N695 Steel properties

N695 Steel Hardness

At standard heat treatment, N695 steel has a hardness of 59-62 HRC. The hardness level changes depending on the heat treatment used. This hardness does not match the hardness of other high-end steels, but it is enough to give this steel great edge retention and wear resistance capabilities.

N695 Steel Wear resistance

This steel has high hardness thanks to the high amounts of carbon and chromium in its composition. Because of the high hardness, N695 steel offers great wear resistance. Knives made from this steel can withstand everyday wear and abrasion and serve you for a very long time.

N695 Steel Edge retention

Another property you will love about knife blades made from this steel is that they retain sharpness for a very long time. This is associated with the high hardness and the carbon content in its composition.

N695 is used to make knives for outdoor use in the wild because the users do not have the time to sharpen the knives after every use.

N695 Steel Corrosion resistance

N695 is a chromium stainless steel hence great in corrosion resistance. The blades of this steel do not rust or stain when used in wet or moist environments. Because of this property, N695 makes a good choice for making fishing and outdoor knives.

To enhance the corrosion resistance, do not leave N695 knives in water for long periods. Also carry out proper care and maintenance, which involves cleaning and drying the knives after use.

N695 Steel Toughness

As a rule of thumb, hard steels are not tough, which is the expectation with N695. However, this rule does not seem to apply with this steel because it offers decent toughness. N695 knives are suitable for outdoor use to mean that they do not break or chip easily on tough applications. The high amounts of molybdenum in its composition contribute to the decent toughness.

N695 Steel Sharpness

One of the major downsides of N695 steel is that it is not easy to sharpen because it is hard steel. If you are a beginner in knife sharpening, getting an edge with blades made from this steel is not easy.

Even with advanced sharpening tools, getting a razor-sharp edge takes more time and energy. On the positive side, though, the blades stay sharp longer, so you do not have to go through the challenging sharpening experience after every use.

- 15" Fixed Blade Knife: Ultra-sharp combat knife, stronger than any hunting knife or bowie knife. Overall Length: 15 inch; Blade Length: 10 inch; Thickness: 5/32 inch (3.8 mm); Weight: 16.8 oz

- Razor Sharp Clip Point Blade: The survival Knife is made of stainless steel for excellent hardness, improved edge retention and rust resistance. Survival knife's clip point blade features saw back, black anodize, ideal for camping expeditions, survival training or military combating

- Rubber Handle & Nylon Sheath: Classic rubber handle of survival knife, provides high friction and comfortable non-slip grip for use. Heavy duty nylon sheath with easy open fastening system and belt hanging system for easy and safe carry

- Sharpener & Fire Starter: Packed below the plastic container in the paper box, please check carefully. Fire starter (black) and a sharpener (sliver) is suitable for outdoors camping

- Occasions: As a perfect camping and hunting survival knife, Mossy Oak fixed blade knives are built to last. it’s suitable for hunter, camper, survivalist or outdoor sports enthusiast so that you can enjoy your adventure

- Knife Dimensions: Straight Edge Hunting Knife/Skinning Knife Overall Length: 10-3/8 inch; Blade Length: 5-1/8 inch; Gut Hook Knife Overall Length: 9-3/8 inch; Blade Length: 4-1/4 inch

- Razor Sharp Clip Point Blade: The black razor-sharp fixed blade is made of premium steel, providing excellent hardness, improved edge retention, toughness, and corrosion resistance

- Full-Tang Camo Handle: Unique yellow camo pattern on handle surface, modish and concealed for outdoors, comfortable grip and balance, ergonomic handle groove is non-slip to use. Lanyard hole for easier carry

- Black Heavy Duty Sheath: The nylon dual-carry black sheath for the MOSSY OAK Break-Up Country Game Processing Knife Set provides easy and secure carry, keeping everything at your fingertips when needed. It features a button snap and belt loop for safe and convenient carrying

- Multiple Use for Outdoors: Suitable for various outdoor situations: hunting, survival, tactical, industrial, and military

- 288 Layer Damascus Hunting Knife – Hand-forged from 1095 & 15N20 high carbon steel with 56–58 HRC hardness for strong edge retention and durability in outdoor conditions.

- Full Tang Fixed Blade Knife – One-piece construction improves balance, strength, and reliability for heavy-duty hunting and bushcraft tasks.

- Ergonomic Rosewood Handle – Designed for secure grip and control during camping, skinning, survival, and field dressing.

- Includes Leather Sheath – Hand-stitched cowhide sheath with secure belt carry for safe storage and easy outdoor transport.

- Outdoor Survival & Camping Knife – Ideal for hunting, bushcraft, camping, hiking, tactical outdoor activities, and collectors of Damascus steel knives.

N695 steel equivalent vs other steels

N695 vs 8Cr13MoV

8Cr13MoV stainless steel is a budget Chinese made steel while N695 is produced by Bohler in Austria. Bohler N695 contains more carbon and chromium than 8Cr13MoV; hence offers better hardness, edge retention, corrosion resistance, and wear resistance. However, with lower hardness, 8Cr13MoV is easier to sharpen and offers better toughness.

N695 vs 440C

N695 and 440C are very similar steels, N695 steel improves on Grade 440C alloy and thus offers slightly higher hardness and wear resistance. However, N695 is a better version of 440C and offers slightly better toughness, wear resistance, and edge retention. But they have the same level of corrosion resistance.

N695 vs S30V

N695 is produced by Bohler while S30v is produced by crucible. S30V steel is more superior steel than the mid-range N695 steel. S30V due to its production process of powder metallurgy offers a more refined grained structure from its alloy. It thus offers better edge retention, corrosion resistance, toughness, and wear resistance. S30V is popular and will be found in most knives.

N695 vs N690

Bohler N695 and 690 can be considered midrange steels. They offer almost similar performance but N690 is much better in edge retention than N695, N690 offers better wear resistance. In terms of toughness, N695 beats N690 due to its low hardness. They however offer similar corrosion resistance and prices are mostly identical.

Bohler N695 vs Sandvik 14C28N

Bohler N695 and 14C28N steel are among my favorites in the market that offer value for money. I have found 14C28N martensitic stainless chromium steel to be a better performer than N695.

14C28N offers better edge retention, toughness, and corrosion resistance. The boosted performance on 14C28N is due to the addition of Nitrogen in its alloy which greatly improves the grain structure.

Bohler N695 vs M390

Both N695 and M390 are made by Bohler. They are good blade steels but M390 is superior to N695 and better in all aspects. It is considered among the best in blade steel currently, M390 offers better edge retention, wear resistance, about five times toughness than N695, and twice the corrosion resistance of N695 steel. It’s expensive and can be found mostly in premium knives.

Bohler N695 vs D2 Steel

N695 steel beats D2 steel in corrosion resistance as Bohler N695 is stainless steel while D2 does not qualify to be stainless steel. D2 steel is a tool steel and thus offers better wear resistance than N695. Sharpening N695 is a bit easier compared to sharpening D2 steel. Both steels can be considered budget steel and their price are near identical. ‘

They offer almost similar performance and your choice for either N695 blade steel or D2 blade should be based on your use scenario. N695 steel will be best suited for corrosive environments.

- Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

- 【Premium Material】: Dealusy clear plastic knives heavy duty are made of food grade polystyrene, total BPA free and toxin free for your healthy meals.

- 【Extra Heavy Duty】: Each plastic knife weights 5.9g, our heavy duty plastic knives disposable with edge thickened design won’t bend easily.

- 【Heat Resistant】: These disposable knives can withstand a high temperature, ideal for hot and cold food.

- 【360 Value Pack】: This disposable knives bulk contains 360 count high quality clear plastic knives, perfect for your everyday use or serving a wedding, panic, party etc.

- 【Disposable or Resuse】: These strudy and durable knives are suitable for disposable use, or you can wash to reuse.

- Lightning-Fast Precision Meets Culinary Power: Inspired by The Scarlet Speedster, this officially licensed The Flash Edition chef knife slices with blistering speed and control. The ultra-sharp 8-12° double-bevel edge glides through prep with zero drag, delivering searing precision and friction-free performance like a Super Hero.

- Forged From Premium German Steel: Crafted from high-performance X50CRMOV15 stainless steel, trusted by chefs worldwide for its balance of sharpness, strength, and durability. With a Rockwell hardness of 54-56 HRC, this blade resists chipping and corrosion, holds its edge under heavy use, and sharpens easily for a lifetime of reliable performance.

- Titanium Nitride Coating for Zero Drag: Finished with a striking gold Titanium Nitride (TiN) coating, this blade isn’t just built to shine — it’s built to zoom. TiN reduces drag and friction for faster, smoother slicing and adds a hard, wear-resistant layer that shrugs off corrosion and everyday wear, keeping your edge sharper, slicker, and longer-lasting.

- Collector-Worthy Detail, Pro-Grade Design: DC The Flash artwork is laser-etched into the mirror-polished blade, celebrating DC’s iconic Super Hero while enhancing slicing performance by reducing food stick. A G10 handle with copper spacer ensures superior balance, comfort, and control, while full-tang construction locks in strength from heel to tip.

- Includes Premium Leather Sheath & Collector Pin: Protect your blade in storage or on the go with a genuine stamped leather sheath featuring official The Flash insignia. Every knife includes an exclusive collector’s pin and Dalstrong’s lifetime warranty plus a 70-day money-back guarantee, because your investment should be protected.

Is N695 steel good knife steel?

The main downside is that it is difficult to sharpen compared to other budget options like 440C. You will find N695 steel in most Boker Solingen Camping knives, fixed blades, and survival knives.