Unveiling the Impressive Strength and Versatility of AEB-L Steel

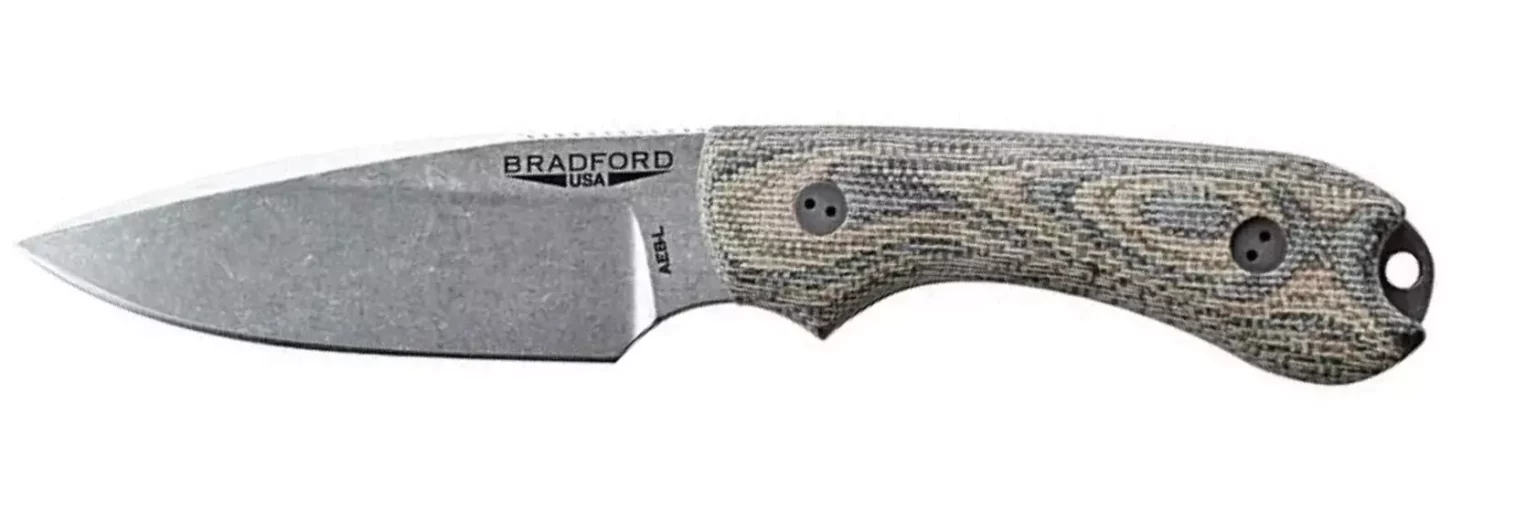

AEB-L steel is revolutionizing the world of blades. Whether you’re a professional chef, a survival enthusiast, or an avid collector, understanding the unique properties of AEB-L steel is vital for making informed decisions and ensuring top performance.

AEB-L steel is renowned for its exceptional strength, durability, and remarkable versatility. This high-quality stainless steel boasts a fine-grained structure that delivers outstanding edge retention, making it a favorite among knife connoisseurs and craftsmen alike.

In this comprehensive guide, we delve deep into the composition and characteristics of AEB-L steel. We explore how its high carbon content, chromium levels, and extensive heat treatment contribute to its superior performance. We also highlight its corrosion resistance, making it ideal for both outdoor adventures and kitchen environments. Through expert insights and practical tips, we equip you with the knowledge needed to choose the perfect AEB-L steel tool for your needs.

Join us as we unravel the mysteries of AEB-L steel and discover why it has become a staple in the world of blades. Learn more about the hidden potential of AEB-L steel and unlock a world of precision and power.

What is AEB-L steel?

The steel stands out because of its high hardness, excellent corrosion resistance, ease of sharpening, and exceptional toughness. AEB-L remains popular among knife makers because of its consistency, it is easy to work with, and it attains a full mirror polish finish.

What’s more, this steel should not be mistaken for AEB. AEB-L contains less carbon than AEB and has finer carbides which do not affect the hardness.

AEB-L Steel Composition

- Carbon C 0.67%: Increases edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

- Chromium Cr 13.00%: Formation of Chromium carbides. Increases the blade’s hardness, tensile strength, and corrosion resistance.

- Phosphorous P 0.02%: Increases the strength and improves the machinability of steel

- Manganese Mn 0.60%: improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

- Silicon Si 0.40%: Increases strength and heat resistance.

- Sulfur S 0.02%: Improves machinability it is regarded as an impurity and may affect performance of the steel.

Properties of AEB-L steel

AEB-L steel Hardness

The hardness of AEB-L is 61-62HRC as per the Rockwell hardness scale. However, specific hardness varies with the heat treatment by manufacturers. With proper heat treatment, the hardness of this steel can go as high as 65HRC.

AEB-L steel heat treatment

AEB-L steel has a simple but effective heat treatment process and is thus loved by most knifemakers. It’s easy to work with and gives good hardness with the right treatment technique. Check Prof. Larrin Thomas’s article on heat treatment of AEB-L stainless steel.

AEB-L steel Toughness

AEB-L stainless steel offers excellent toughness, better than what is expected from steel with its hardness level. The higher toughness of AEB-L is due to the small volume of extremely tiny carbides that improve its grain structure

AEB-L stainless steel toughness is among the best out there. Its toughness level can be rated as a 9 out of 10. AEB-L stainless steel can only be bettered by very few steels out there, these include 8670 steel, 5160 steel, and Z-tuff.

AEB-L steel Edge Retention

You will be pleased with how long this steel keeps an edge. The good edge retention of AEB-L is associated with the finer carbides in their composition and the high hardness.

It is worth noting that AEB-L stainless steel is still lower than that of 440C stainless steel. However, the edge retention can be greatly increased if AEB-L steel is hardened to well in such a way that the hardness level goes beyond 62HRC.

AEB-L steel Wear resistance

Another area of excellence for this steel is its wear resistance, which is attributed to its high hardness. With high wear resistance, this steel can withstand everyday wear and tear. Its blades will not deform even with frequent use and sharpening.

AEB-L steel Corrosion resistance

Thanks to the high chromium in its composition, AEB-L offers great corrosion resistance. Knives made from steel can resist rusting even with minimal care. However, this does not mean that you neglect the blades. Proper care helps to boost its corrosion resistance.

What’s more, being stainless steel, your knives will never get stains as well. AEB-L stainless steel corrosion resistance is comparable to the likes of Japanese AUS 8 steel and the popular Chinese-made 8Cr13MoV steel.

Sharpening AEB-L steel

Being hard steel, you must be stressed about sharpening. The good news is, despite the high hardness, AEB-L steel is very easy to sharpen. This property is associated with small and fine carbides in its structure. You will be able to attain a sharp edge faster, even with simple sharpening tools.

Machinability of AEB-L steel

AEB-L is very consistent and requires basic heat treatment. It is easy to work with on the grinder, meaning that it is less costly and takes less of the knife maker’s efforts.

In addition, it attains a full mirror polish making it a favorite for both the knife smith and users.

Related: Discover The Best Serrated Knives

AEB L steel equivalent

AEB-L steel is similar to Sandvik 13C26 stainless steel and FC61 steel. AEB-L is also comparable to 420HC stainless steel, both steel offer similar exceptional toughness. They also offer an almost Identical level of edge retention but 420HC offers marginally better corrosion resistance. Sharpening either of these steel will be an easy task.

AEB-L steel vs CPM 3V

The first notable difference is that AEB-L is stainless steel while CPM 3V is not. This makes 3V more prone to corrosion. AEB-L stainless steel contains about 13% chromium while CPM 3V contains 7.5%. So in terms of corrosion and rust resistance AEB-L steel will outperform 3V steel, this is a key factor you should think about when choosing between these two steel blades.

Both AEB-L stainless steel and CPM 3V steel offer the same level of toughness. Their toughness level is among the best in the steel world, their toughness can be rated at 9 out of 10 which is at par with 14C28N stainless steel and only bettered by likes of low alloy 5160 and High alloy Z-Tuff steel which both are not stainless steel.

When it comes to edge retention they both offer almost identical performance but CPM 3V slightly outperforms AEB-L stainless steel with a negligible margin. It is worth noting that sharpening CPM 3V steel will also be a little easier as it offers slightly lower hardness than AEB-L stainless steel.

While CPM 3V offers slightly better edge retention and ease of sharpening I believe looking at the properties listed, AEB-L stainless steel is better steel than CPM 3V steel as it requires little maintenance compared to the Non-stainless CPM 3V steel in terms of corrosion and rust resistance.

Related: Why Pancake Knife Sheaths Are Essential For Every Home Chef

AEB-L steel vs VG10 Steel

Both AEB-L steel and VG10 steel are stainless steel with over 13% chromium in their alloying elements. Japanese VG10 steel offers better corrosion and rust resistance than AEB-L steel as it contains close to 15.5% chromium elements in its alloying composition.VG10 steel tends to be categorized as high-end stainless steel as it also contains more elements like Cobalt which greatly improves its corrosion resistance.

While they both offer almost identical levels of hardness, a VG10 stainless steel knife will offer better edge retention than an AEB-L stainless steel knife. This can be attributed to the presence of Vanadium Carbides in its alloy which are excellent when it comes to edge retention and wear resistance. It will however be more difficult to sharpen VG10

AEB-L stainless steel redeems itself and beats VG10 steel when it comes to toughness. The level of toughness you get in an AEB-L stainless steel blade can only be bettered by a few steels out there, its level of toughness can be equated as a 9 out of 10 while that of VG10 steel is a 4 out of 10. VG10 stainless steel toughness is similar to its Japanese counterpart Super Gold 2 (SG2) and Crucible’s S30V stainless steel.

AEB-L steel vs M390 Steel

Both AEB-l steel and Bohler M390 steel are stainless steel with over 13% chromium in their composition, however, M390 steel is a premium steel with about 20% chromium elements in its composition. It is among the best blade steel out there with extremely high corrosion resistance, it is comparable to 20CV, CTS 204P, and S110V steel.

Bohler M390 Stainless steel offers better edge retention than AEB-L stainless steel despite both knife steels offering a similar level of hardness at 62HRC. This is attributed to the exceptional powder metallurgy production process of Bohler industries and the most important addition of 4% vanadium in its composition.

The 4% vanadium enables the formation of hard carbides which are excellent when it comes to edge retention and wear resistance but difficult to sharpen. You will thus have an easier time sharpening the AEB-l steel knife than an M390 steel knife.

Where AEB-L stainless steel greatly outperforms M390 steel is in toughness. M390 blade steel offers poor toughness due to its high composition of chromium and vanadium which form brittle carbides that can easily break. AEB-L blade steel on the other hand contains very fine carbides and lacks a huge volume of brittle carbides thus delivering exceptional toughness.

AEB-L steel vs N690 steel

Bohler N690 steel and AEB-L steel are stainless steel with over 13% Chromium in their alloy. Bohler N690 stainless steel however offers better corrosion resistance than AEB-L by a huge margin due to 17% Chromium in its alloy. Bohler N690 stainless steel is almost as good as its premium sibling Bohler M390 stainless steel.

N690 steel blade will also offer better edge retention when compared to AEB-L steel. The difference in edge retention is however not as massive as that of corrosion resistance. The better edge retention is attributed to the Bohler Powder Metallurgy process that refines the grain structure of steel for optimal performance.

Bohler N690 Blade steel performance is mostly comparable to Japanese VG10 than to AEB-L steel. N690 contains some vanadium and cobalt in its composition just like VG10 steel.

AEB-L stainless steel however offers excellent toughness, the toughness of AEB-L blade steel is more than twice that of Bohler N690 Blade steel. You will get a tougher knife with AEB-L steel most suitable for outdoors, camping, and other demanding applications like batoning.

It will be much easier to sharpen an AEB-L knife as compared to sharpening N690 steel due to the improved wear resistance of AEB-L knife steel.

AEB-L vs. Elmax

Both AEB-L and Elmax steel are manufactured by the same company but differ in properties and performance. Elmax is a premium steel with more carbon and chromium than AEB-L, it thus offers better edge retention, wear resistance, and corrosion resistance.

AEB-L stainless steel will however offer better toughness than ELmax stainless steel due to its fine-grained structure. Elmax can be regarded as better blade steel than AEB-L steel for pocket knives that are not subjected to tougher applications.

AEB-L vs 440C

The difference between 440C and AEB-L is that 440C has more carbon and chromium elements in its alloy composition, which gives it a harder edge. The high amount of chromium also makes 440C stainless steel better in corrosion resistance. On the other hand, AEB-L beats 440C in toughness and ease of sharpening.

See also: Nitro-V Steel, an improved version of AEB-L steel with added Vanadium and Nitrogen.

Is AEB-L good knife steel?

AEB-L steel is good knife steel because it offers high hardness, exceptional toughness moderate edge retention, and good corrosion resistance. AEB-L stainless steel is also very easy to sharpen. The steel is suitable for making hunting knives, camping knives, or hiking knives, What’s more, it is very affordable.

- When you order 1 quantity, you receive a 12" piece

- This steel is fully stainless steel but perform much like carbon steel. It is Descaled and Annealed.

- Extremely easy to grind

- Heat treat like 440c

- Very Easy to polish and buff

- PARING KNIFE - The Middleton Echo paring knife is a 4 Inch knife for very specific tasks that require extreme precision and fine cutting.

- JAPANESE INSPIRED BLADE - Forged out of AEB-L stainless steel. Middleton Echo blades are known for corrosion resistance, hardness, and ease of sharpness. The Echo has a 60 Rockwell Hardness with a sharp 12° blade angle. Ultra thin blade measures 2.25 at the heel and 0.18mm at the edge.

- ERGONOMIC GRIP - Echo knives are made from Dymalux, which is dyed birch veneers. Offers premium comfort minimizing wrist tension, while providing secure, comfortable, controlled grip.

- AMERICAN MADE - Handcrafted in the USA by South Carolina based blade smith, Quintin Middleton. Producing knives for over 20 years, Quintin puts great care into each piece and he stands by the simple philosophy that every great chef needs a great knife.

- FEATURED IN - Middleton Made Knives have been featured in New York Times, Forbes, Washington Post, GQ, Food & Wine, and Bloomberg for excellent craftsmanship, artistry, and style.

- CHEFS KNIFE - The Middleton Echo Chef's Knife is an all-purpose knife with an 8 inch blade that is ideal for a wide variety of cutting tasks that is perfect for slicing, dicing, and chopping fruits, vegetables, and other foods.

- JAPANESE INSPIRED BLADE - Forged out of AEB-L stainless steel. Middleton Echo blades are known for corrosion resistance, hardness, and ease of sharpness. The Echo has a 60 Rockwell Hardness with a sharp 12° blade angle. Ultra thin blade measures 3mm at the heel and 0.18mm at the edge.

- ERGONOMIC GRIP - Echo knives are made from Dymalux, which is dyed birch veneers. Offers premium comfort minimizing wrist tension, while providing secure, comfortable, controlled grip.

- AMERICAN MADE - Handcrafted in the USA by South Carolina based blade smith, Quintin Middleton. Producing knives for over 20 years, Quintin puts great care into each piece and he stands by the simple philosophy that every great chef needs a great knife.

- FEATURED IN - Middleton Made Knives have been featured in New York Times, Forbes, Washington Post, GQ, Food & Wine, and Bloomberg for excellent craftsmanship, artistry, and style.