When it comes to high-performance knife steels, two popular options that often stand out are K390 and M390. These premium blade materials have gained a strong following among knife enthusiasts and professionals for their exceptional qualities. In this article, we will delve into the details of K390 and M390, examining their composition, hardness, toughness, edge retention, corrosion resistance, sharpening characteristics, applications, cost, availability, and more. By the end, you will have an in-depth understanding of these remarkable knife steels, empowering you to make an informed decision when selecting your next blade.

About K390

K390 is a high-speed tool steel that boasts impressive qualities for knife applications. It is known for its exceptional wear resistance and edge retention, making it an excellent choice for heavy-duty cutting tasks. The composition of K390 typically includes a significant amount of carbon, chromium, tungsten, vanadium, and cobalt. This combination of elements contributes to its hardness, toughness, and ability to maintain a sharp edge even under demanding conditions.

Whether you’re an outdoor enthusiast venturing into the wild, a professional tradesperson in need of a reliable tool, or a knife enthusiast seeking the pinnacle of cutting performance, the K390 knife is a force to be reckoned with.

However, it’s important to note that while the K390 knife exhibits exceptional cutting performance, it requires proper care and maintenance. Being a high-speed tool steel, it is not stainless and is susceptible to corrosion if not properly cared for. Regular cleaning, drying, and the occasional application of a thin layer of oil will help protect the blade and preserve its longevity.

In the world of heavy-duty cutting, the K390 knife has earned its reputation as a dependable and high-performance tool. Whether you’re venturing into the wilderness or engaging in demanding cutting tasks, the K390 knife will exceed your expectations and redefine what a cutting tool can achieve. Get ready to unleash the power of the K390 knife and experience cutting excellence like never before.

[affiliatable id=’172828′]

About M390

In the realm of high-performance knife steels, one name that stands out for its exceptional qualities is M390. Renowned for its outstanding edge retention, corrosion resistance, and versatility, the M390 knife has gained popularity among professionals and enthusiasts alike. In this article, we will delve into the remarkable characteristics of the M390 steel, exploring its composition, hardness, toughness, corrosion resistance, and applications. By the end, you’ll understand why the M390 knife is a top choice for those seeking uncompromising cutting performance.

To ensure the longevity of your M390 knife, proper maintenance is essential. Regular cleaning, drying, and the occasional application of a thin layer of oil will help protect the blade and preserve its corrosion resistance. It’s also important to employ appropriate sharpening techniques and tools to maintain the desired edge geometry and optimize cutting performance.

The M390 knife represents the pinnacle of cutting excellence. With its remarkable edge retention, corrosion resistance, and versatility, the M390 knife is a top choice for those seeking a cutting tool that excels in any situation. With an M390 knife in your hand, you can confidently tackle any cutting task with precision, durability, and reliability. Prepare to unlock a new level of cutting performance with the M390 knife and experience the epitome of knife craftsmanship.

[affiliatable id=’172830′]

Composition: K390 vs M390

The composition of a knife steel plays a crucial role in determining its performance characteristics. K390 typically boasts around 2.45% carbon, 4.20% chromium, 6.30% tungsten, 9.00% vanadium, and 2.00% cobalt. This composition results in a steel that exhibits exceptional hardness, wear resistance, and toughness. On the other hand, M390 consists of approximately 1.90% carbon, 20.00% chromium, 0.70% molybdenum, 1.00% vanadium, and 4.00% tungsten.

These variances in composition play a significant role in determining the unique characteristics and performance of each steel.

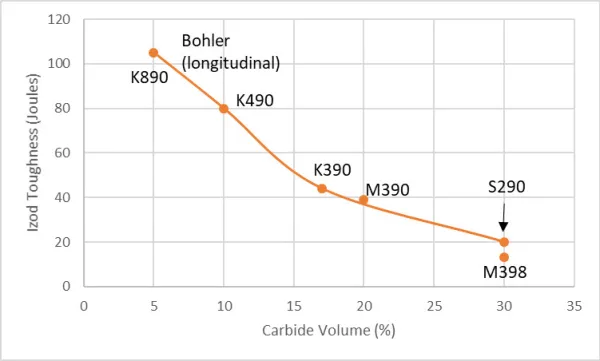

Hardness and Toughness: K390 vs M390

The hardness and toughness of a knife steel are vital considerations for its performance in various cutting tasks.

K390 is known for its exceptional hardness, typically ranging from 63 to 64 HRC (Rockwell hardness scale). This high hardness level allows it to maintain an exceptional cutting edge for extended periods, even when subjected to heavy use.

M390, while slightly lower in hardness, still boasts an impressive range of 58 to 61 HRC. This compromise in hardness contributes to M390’s improved toughness, making it more resistant to chipping and breakage under impact.

Edge Retention: K390 vs M390

Edge retention is a vital factor to consider when choosing a knife steel. Both K390 and M390 excel in this regard, offering prolonged edge retention capabilities.

K390’s high wear resistance allows it to retain its sharpness even when subjected to heavy use and abrasive materials. Similarly, M390 boasts remarkable edge retention capabilities, allowing it to retain its cutting performance for extended periods without frequent sharpening. Whether you’re tackling tough tasks or need a reliable cutting edge for prolonged periods, both steels deliver impressive results.

Corrosion Resistance: K390 vs M390

Corrosion resistance is a critical aspect, especially for knives exposed to moisture and harsh environments.

M390 has an advantage in this area due to its higher chromium content. The substantial chromium presence forms a protective layer on the steel’s surface, making it highly resistant to rust, staining, and corrosion.

K390, although not as corrosion-resistant as M390, still offers decent resistance and requires proper maintenance to prevent corrosion. Regular cleaning, drying, and occasional application of a thin layer of oil can help mitigate the risk of corrosion and ensure the longevity of K390 knives.

Both K390 and M390 exhibit exceptional wear resistance, which is crucial for knives that undergo heavy use or cutting tasks involving abrasive materials.

K390’s high tungsten and vanadium content contribute to its superior wear resistance, allowing it to withstand prolonged use without significant wear. Similarly, M390’s combination of elements, including tungsten, vanadium, and chromium, provides excellent durability and resistance to wear, making it a reliable choice for demanding applications.

Sharpening Characteristics: K390 vs M390

Both K390 and M390 are known for their high hardness, which can make them relatively challenging to sharpen compared to softer steels. They are considered harder to sharpen compared to softer steels.

However, with the right tools and techniques, achieving a razor-sharp edge is achievable. Diamond stones or ceramic rods are often recommended for sharpening these steels due to their abrasion-resistant properties. It’s essential to approach the sharpening process with patience, precision, and the proper angle to maintain the desired edge geometry.

Applications: K390 vs M390

K390 and M390 find applications in various knife styles and tasks. Due to its exceptional wear resistance and toughness, K390 is particularly well-suited for heavy-duty knives used in demanding environments such as survival knives, camping tools, and industrial blades. On the other hand, M390’s balanced properties, including excellent edge retention, corrosion resistance, and stainless characteristics, make it a popular choice for everyday carry (EDC) knives, folding knives, and high-end culinary knives.

Price: K390 vs M390

When considering K390 and M390, it’s important to factor in the cost and availability of knives made with these steels. Both steels fall into the premium category, often commanding higher prices compared to more common steels. Availability may vary depending on the knife manufacturer and specific models. It’s important to research reputable brands and suppliers to ensure you’re getting an authentic knife made with the desired steel.

User Experiences and Expert Opinions: K390 vs M390

Gathering insights from experts and users who have hands-on experience with K390 and M390 can provide valuable perspectives. Exploring knife enthusiast forums, online communities, and expert reviews can offer real-world experiences, practical feedback, and additional information to aid in decision-making. Hearing from those who have hands-on experience with these steels can provide valuable insights into their strengths, limitations, and practical applications.

[affiliatable id=’172639′]

Click for more knife comparisons.