What is Damascus steel?

Damascus steel is legendary steel recognized for its streaked watered design and exceptional hardness. Back in the day, swords manufactured from Damascus steel stood out among many because they were beautiful, tough, maintained a sharp edge, and were very flexible.

Damascus blade steel was superior and durable compared to weapons made from iron or carbon. Swords made from Damascus steel are still available, proving Damascus steel quality.

Damascus steel, in essence, is a combination of two sheets of steel or more, each with different properties layered and forged together to produce one single steel with an aesthetically pleasing pattern.

Is Damascus blade steel still the best in the market? Modern high carbon steel beats the quality of Damascus steel. However, the original Damascus steel remains the legendary steel of its day.

What’s more, the secret to manufacturing the original Damascus steel (wootz steel) was lost along the way. Although modern Damascus steel is still of high quality, it is not the same as the original steel called wootz steel.

Origin of Damascus steel?

Historians do not clearly explain the origin of “Damascus” when naming steel. Here are three possibilities drawn from references and origin stories that explain why the steel was called Damascus steel:

1. Named after Damascus city where the steel was made.

2. The name refers to swords traded or bought from Damascus

3. The patterns on the blades resemble damask fabric which is named Damascus; hence the steel is named after the fabric.

Types of Damascus steel

Cast Damascus steel

Cast Damascus is the original Damascus steel, also known as wootz steel. It was made in India around 200 years ago. The skills and art of making the original steel were lost in the 1700s, declining its production.

A lot of research has been put in place to replicate the cast wootz steel. Still, unfortunately, no one has been able to replicate the original steel. The original Damascus technique has very little to no information on how to replicate it.

Pattern-Welded Damascus steel

Pattern welded steel is modern-day Damascus steel. The steel is manufactured by layering two types of steel together and hammering them at high temperatures to forge them together.

This process gives the steel a watery pattern, making it look like the original Damascus steel. However, the pattern is not what makes it Damascus steel but the composition and the manufacturing process.

Suppose you are on the market to buy Damascus knife steel today. In that case, you are presented with two options, the pattern welded above or a cheaper option where the metal has been surface etched to attain the patterns.

If all you want is the patterns, the latter option is the best for you, but the patterns will fade away with usage.

Companies like Sweden-based Damasteel produce high-quality powder metallurgy Damascus steel with excellent edge retention while providing superior corrosion resistance. Their proprietary Damascus knife steel includes DS93X martensitic steel and DS95X Austenitic steel.

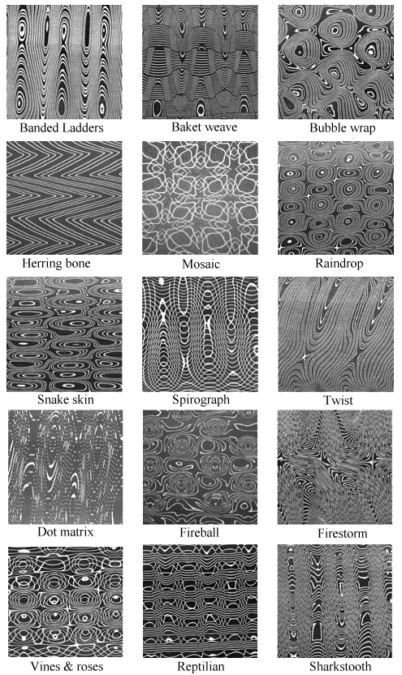

Apart from the excellent blade properties, the steels come with a wide range of patterns like a ladder, thor, Ægir Björkmans Twist, among others to choose from. Depending on the blade size and types (folders or fixed).

Damascus knives

There are a variety of Damascus knives for a range of uses ranging from kitchen to hunting knives. The materials put together to make Damascus knives depend on the type of knife and the intended use.

The advantage of buying Damascus knives is that they are strong, long-lasting, and beautiful. Below are common types of Damascus knives:

- Hunting knives

- Tactical (folding or fixed) knives

- Flip-flop knives

- Carving knives

- Rigging knives

- Serrated knives

Caring for Damascus steel knives

It is essential to follow the manufacturer’s guidelines on maintaining Damascus steel. Ensure to wash and dry the knives immediately after use. If your blades are manufactured from carbon Damascus steel, they are susceptible to rust and corrosion, requiring more care.

Ensure to maintain the edge with the right sharpening tools, whetstones do a great job. Also, oiling the blades often keeps their shine and patterns. If you do not have time for regular care and maintenance, invest in Damascus blades formulated from stainless steel.

Is Damascus steel good for kitchen knives?

The performance of Damascus knives depends on the steel used to forge the blade. Damascus forged from high-quality steel makes strong and long-lasting blades with unique and beautiful designs. Damascus steel’s high performance and aesthetics make it a good choice for kitchen knives.

Most Damascus kitchen knives are forged from steels with good corrosion resistance, edge retention, and toughness. Standard steels used include VG1, VG10, VG Max, AUS 8, and AUS 10 Steel.

Damascus knife benefits

- Aesthetics: Damascus knives are beautiful, this the key to their existence currently. Most people however prefer the aestheitcally pleasing dozens of patterns to choose from and thus the high popularity.

- The second benefit to damascus blade steel is the combination of low and high carbon steel allows the low carbon steel to wear out a bit quicker leaving the high carbon intact. This in turn creates small microscopic serration which may provide faster cutting. However this cutting wont be as smooth as a sharp fine edge with no serrations.

- Artistic Value: an original wootz steel will be a priced possession as the production process has been lost over the ages. A wootz damascus knife will be unique and cost a lot more than normal finds.

- Damascus knives are made to fit a specific purpose. Since patterned Damascus requires two or more steels, a manufacturer will most likely pick the best steel that suit the specific need. You will find most Japanese Damascus kitchen knives made from a steel like VG10 stainless steel which is excellent for kitchen need as its, corrosion resistance and maintains a sharp edge.

Damascus Patterns

How to make Damascus steel patterns

Making Damascus patterns depends on the forging technique. The common ladder Damascus pattern is made by selectively grinding the forged steel blade in a ladder pattern then forging it to the finished product.

The twisted ladder pattern on the other hand is made by twisting the forged blade while still hot in a bench grip. After twisting the blade, it is later forged more to obtain the pattern when etched.

Etching Damascus steel

Etching Damascus steel is the final step to creating Damascus steel patterns. Etching exposes the pattern made from forging the steel. Etching is done by selective chemical corroding to produce shades of the different constituents of the steel.

The forged Damascus blade steel is immersed in the etching solutions. The etching solution typically is an acid like ferric chloride acid, sulphuric acid, vinegar, battery acid, or even coffee.

The best and easiest way to get the pattern is to follow these simple steps

1. Soak the forged Damascus blade into the acid solution for about twenty minutes

2. Remove the Damascus blade from the acid solution and dip it into the baking soda solution. This will stop the acid reaction on step 1 above.

3. Get a sponge scrub and scrub the Damascus blade, cleaning it in the baking soda water solution. This will allow the removal of oxides from the carbon.

4. You can repeat the process 4 to 5 times to fully unveil the pattern. Note that each time you do it the low carbon steel gets “eaten” away by the acid making the blade weaker.

Are Damascus steel knives worth it?

In terms of aesthetics, yes they are worth the price, performance no. Back in the day, Damascus steel would provide a balance between iron and high carbon steel in terms of performance.

However, steel technology has greatly improved and most Powdered steels like MagnaCut Steel will outdo patterned Damascus steels.