What is AN-58 Steel?

AN-58 steel is stainless steel as it contains about 13.5% chromium enough to make it stainless steel. Therefore, its products can be used in corrosive

AN-58 steel is stainless steel as it contains about 13.5% chromium enough to make it stainless steel. Therefore, its products can be used in corrosive

DC53 steel is used in forging, blanking, shearing, and knife making. It is recommended for the manufacture of budget knives to be used in applications

Why is it special? L6 steel is special because it is heated and worked on to form Bainite, which gives the steel a high hardness

Vanadis 4E steel is great knife steel that offers a more balanced approach to toughness, edge retention, and corrosion resistance. The steel does not contain

Z-Max steel is referred to as Z-Max PM steel with the PM signifying the powder metallurgy production process which enables the formation of a huge

There have been two versions of INFI steel. The older version contained nitrogen elements for hardening because it contained low amounts of carbon. The current INFI

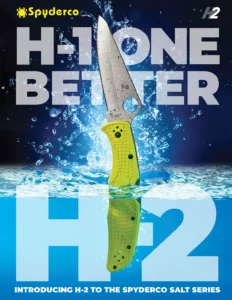

Although it is a huge loss to the steel industry, there is a positive side because Spyderco, in partnership with other steel manufacturing partners in

K720 tool steel is also used for making industrial machine knives, punches, gauges, measuring tools, and jigs. The biggest downside of K720 blade steel is

However, it does not perform very well in various aspects like edge retention and corrosion resistance, so the manufacturer recommends a corrosion-resistant coating on the