What is Za-18 Steel?

Za-18 steel composition is also highly similar to Bohler N690 steel. N690 steel has excellent knife properties and has been around for longer so we

Za-18 steel composition is also highly similar to Bohler N690 steel. N690 steel has excellent knife properties and has been around for longer so we

Fallkniven sources their core, SGPS, from Tekefu and renames it to 3G after laminating it with VG2 steels. 3G knife steel is suitable for the

9260 spring steel is used in making swords and katanas due to its excellent toughness and ability to withstand high lateral bends. This property makes

The company claims that powder AR-RPM9 stainless steel will boost the performance of the knife offerings in the budget category because its performance matches that

7Cr17MoV stainless steel has been in the lead in the production of survival knives, hunting knives, cleavers, and large chef knives. In addition to the

Ginsan steel is closely identical to Shirogami #2 steel, but its high purity reduces its Rockwell hardness making it easier to sharpen than the Aogami

SUS410 stainless steel is supplied in its hardened but Machinable state and used for general-purpose applications that require moderate strength, moderate heat treatment, and corrosion

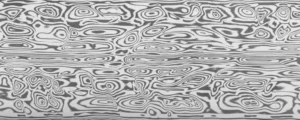

What is Damascus steel? Damascus steel is legendary steel recognized for its streaked watered design and exceptional hardness. Back in the day, swords manufactured from

HAP40/SUS410 steel is laminate steel, whereby HAP40 steel, which is not stainless steel, is coated with SUS410 stainless steel. The stainless steel protects the blades