In this article, we will compare M390 Steel and CPM 3V Steel in terms of composition, toughness, edge retention, corrosion resistance, ease of sharpening, and price.

M390 and CPM 3V are both popular steels that are used in the manufacture of knives and other cutting tools.

Bohler M390 steel is known for its excellent wear resistance, edge retention, and corrosion resistance, while CPM 3V is known for its exceptional toughness and is often used in outdoor knives where it may be subjected to heavy use and abuse.

About M390 Steel

M390 steel is a martensitic stainless steel that is produced by Bohler following the powder metallurgy process.

Bohler M390 steel was formulated to be highly wear-resistant and corrosion-resistant steel. It is considered premium steel and thus tends to be pricier than other knife steels.

M390 stainless steel is used in the manufacture of knives, medical equipment, the food, and processing industry, and in pill-punching dies.

About CPM 3V Steel

CPM 3V steel is a tool steel known for its exceptional toughness and wear resistance, it is manufactured by Crucible Industries following the Particle Metallurgy Process.

CPM 3V steel is non-stainless steel and does not provide good corrosion resistance despite being used in most outdoor knives.

CPM 3V is widely used in the manufacture of knives and other cutting tools, Punches, and Dies due to its extreme wear resistance and ability to withstand heavy application without chipping and breaking.

M390 Vs CPM 3V: Comparison Table

| Specification | M390 Steel | 3V Steel |

|---|---|---|

| Composition | Carbon 1.90% Chromium 20.00% Molybdenum 1.00% Silicon 0.40% Vanadium 4.00% Manganese 0.30% Tungsten 0.60% Silicon 0.70% | Carbon 0.80% Chromium 7.50% Molybdenum 1.30% Vanadium 2.75% |

| Rockwell Hardness | 60-62 HRC | 58-60 HRC |

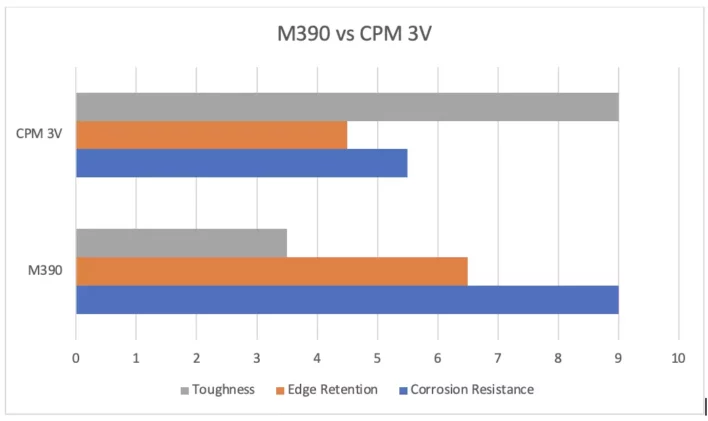

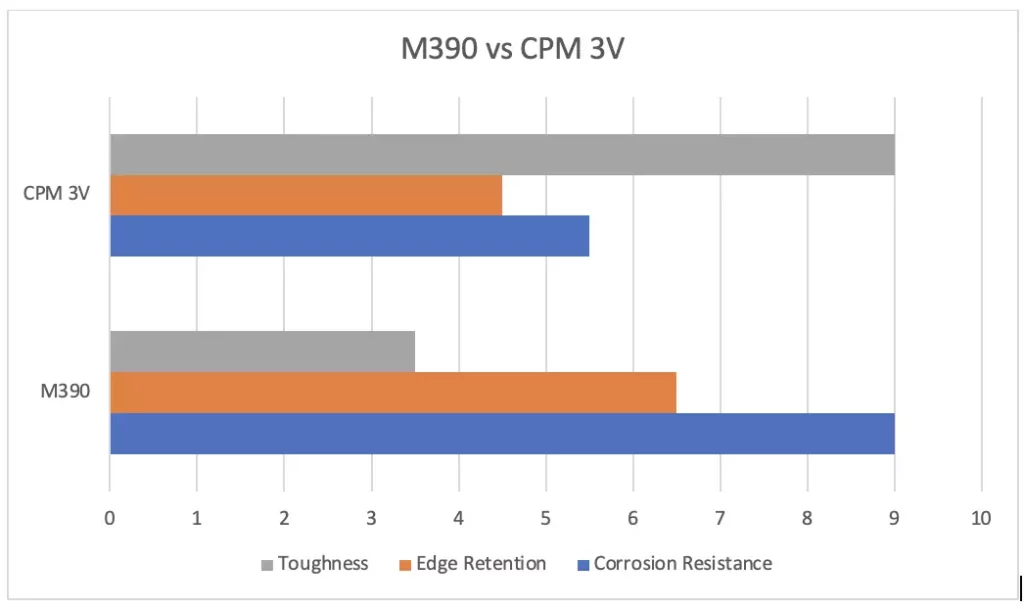

| Edge Retention | 6.5/10 | 4.5/10 |

| Toughness | 3.5/10 | 9/10 |

| Corrosion Resistance | 9/10 | 5.5/10 |

| Ease of Sharpening | Hard | Moderate |

| Price | Expensive | Mid-range |

Toughness

CPM 3V tool steel is known for its exceptional toughness, making it an excellent choice for knives that may be subjected to heavy use and abuse like batoning. In comparison to M390 steel, CPM 3V offers almost three times the toughness of M390. According to Crucible Industries, CPM 3V steel has the highest impact toughness of any tool steel in its range of wear resistance.

This makes CPM 3V an excellent choice for use in outdoor knives where the knife may be subjected to high levels of stress. 3V steel toughness and wear resistance make it a highly durable and reliable choice for a wide range of applications.

Edge Retention

Both M390 and CPM 3V steel offer exceptional wear resistance, making them good choices for use in most knives. However, M390 stainless steel has an additional advantage in that it also has better edge retention than CPM 3V steel.

M390 steel is known for its excellent edge retention, which has been confirmed through various tests such as CATRA tests from Bohler Industry. This is due to its high carbide content and the addition of 4% vanadium content, which improves the steel’s overall ability to hold a sharp edge.

The high carbide content and vanadium addition contribute to M390’s high Rockwell hardness over 3V steel, which is a key factor in edge retention. This makes M390 the better choice over CPM 3V for use in premium knives.

Corrosion Resistance

M390 steel is an exceptional stainless steel produced to provide high wear resistance and high corrosion resistance. It contains 20% chromium content, which gives it excellent corrosion resistance and makes it suitable for use in wet or humid environments.

In contrast, CPM 3V steel is a non-stainless steel with only 7.5% chromium content and is not as resistant to corrosion as M390 stainless steel. 3V corrosion resistance is better than most nonstainless steel like D2 steel but does not offer corrosion resistance similar to that of stainless steel.

Ease Of Sharpening

Sharpening CPM 3V steel is a little easier than sharpening M390 steel. This is because CPM 3V steel has a lower Rockwell hardness than M390 steel, which translates to it being slightly softer and easier to work with.

The lower Rockwell hardness also means that CPM 3V is less prone to chipping or breaking during the sharpening process. While CPM 3V is still a relatively hard steel and may require some effort to sharpen, it is easier to work with than M390 steel.

This can make CPM 3V a more convenient choice for those who need to frequently sharpen their knives.

It is worth noting that While CPM 3V steel is generally easier to sharpen than M390 steel due to its lower Rockwell hardness, M390 is not extremely hard to sharpen.

This is because M390 contains a large number of chromium carbides than vanadium carbides, which are easier to sharpen on common sharpening abrasives made of aluminum oxide.

As a result, M390 knives can be sharpened using common sharpening equipment and techniques, although it may require a little more effort than CPM 3V knives.

Intention Of Use

The intention of use is an important factor to consider when choosing between M390 and CPM 3V blades. M390 steel is most often used in high-end knives that require a sharp and durable edge.

It is well-suited for precision cutting tasks, making it a popular choice among chefs, knife enthusiasts, medics, and other professionals who require a very sharp and precise blade.

In contrast, CPM 3V is also commonly used in knives and tools, but for its toughness and wear resistance thus the ability to hold up to heavy use and abuse.

CPM 3V steel is often used in outdoor knives where the knife may be subjected to extreme conditions and high levels of stress. As a result, CPM 3V is a popular choice among outdoor enthusiasts, hunters, and military personnel.

Another key point to consider is that the level of maintenance required can affect the convenience and overall lifespan of the knife.

CPM 3V knives are non-stainless steel and may require more frequent cleaning and oiling to prevent rust while M390 knives are stainless steel with excellent corrosion resistance, so they do not require the same level of maintenance to prevent rust as CPM 3V knives.

Price

When it comes to the price of M390 and CPM 3V knives, M390 knives tend to be more expensive. This is partly due to M390 steel’s high performance and demand among knife enthusiasts and professionals.

M390 offers excellent corrosion resistance, edge retention, and wear resistance, making it a popular choice for premium knives. As a result, M390 tends to command a higher price than CPM 3V.

While CPM 3V is also high-performance steel it is generally more affordable than M390 due to its slightly lower demand and lower performance in aspects of corrosion and edge retention.

Final Thoughts On M390 Vs CPM 3V

In conclusion, M390 and CPM 3V are both high-wear resistance steels that are commonly used in the manufacture of knives and other cutting tools. M390 steel gives excellent edge retention and corrosion resistance, making it a popular choice for precision cutting knives.

Bohler M390 is also produced using the powder metallurgy process and has a slightly higher Rockwell hardness than CPM 3V. CPM 3V, on the other hand, is known for its toughness and is often used in outdoor and tough applications where it may be subjected to high stress.

3V steel is easier to sharpen than M390 stainless steel and is generally more affordable. CPM 3V is thus better suited for tough applications. While M390 is a versatile steel that can be used for a wide range of purposes, including kitchen knives and EDCs.