What is A Caping Knife and what is it used for?

If you are into outdoor adventure, especially hunting, you could have plenty of knives for different uses. But for skinning, nothing offers the perfect convenience,

If you are into outdoor adventure, especially hunting, you could have plenty of knives for different uses. But for skinning, nothing offers the perfect convenience,

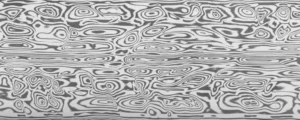

What is Damascus steel? Damascus steel is legendary steel recognized for its streaked watered design and exceptional hardness. Back in the day, swords manufactured from

Tanto blades are characterized by a sharp-angled tip, with a small curve or belly towards the main edge. The tip of the Tanto blades somehow

One of the main things to consider when buying a folding knife is the locking mechanism. There are several locking mechanisms, but liner lock and

HAP40/SUS410 steel is laminate steel, whereby HAP40 steel, which is not stainless steel, is coated with SUS410 stainless steel. The stainless steel protects the blades

Under 3-inch pocket knives are helpful for everyday cutting needs and may be suitable for official places like offices, unboxing, and minimal cutting. Under 3-inch

DLC is the acronym for Diamond-like Carbon Coating. DLC coating is made from carbon atoms, and it is the hardest coating that can be applied

DS93X Steel is a Damascus stainless steel produced from metallurgy of powders by Sweden-based Damasteel. The Steel can be produced to contain over 100 layers

RWL 34 is exceptional steel in the knife-making industry. It offers all characteristics any knife makers would ask to make high-quality knife blades. It offers