What is FC61 Steel?

When properly heat-treated and tempered, the steel makes tough, durable, and corrosion resistance blades. FC61 steel is also used to manufacture high-end knives in Seki, Japan. It is ideal for razor blades and surgical knives too.

FC61 Steel Composition (FC61 Steel Chart)

- Carbon C 0.68%: Increases edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

- Chromium Cr 13.00%: Formation of Chromium carbides. Increases the blade’s hardness, tensile strength, and corrosion resistance.

- Manganese Mn 0.70%: improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

- Silicon Si 0.4%: Increases strength and heat resistance.

- Sulfur S 0.01%: Improves machinability it is regarded as an impurity and may affect the performance of the steel.

- Phosphorous P 0.02%: Increases the strength and improves the machinability of steel but is regarded as an impurity.

Properties of FC61 steel

FC61 Steel Hardness

FC61 stainless steel exhibits a Rockwell hardness of up to 61HRC. The achieved hardness varies with the heat treatment technique and the tempering time of the manufacturer. High hardness positively influences properties like edge retention and wear resistance of the blade steel.

FC61 Steel Edge retention

With a Rockwell hardness of 61HRC, FC61 blade steel offers good edge retention though not the best out there, particularly in stainless steel. Its edge retention is enough to last several cuts but will need sharpening when constantly used.

FC61 Steel edge retention is lower than Japanese VG10 steel, also used in most kitchen knives but is at the same level as AUS 8 steel and 8Cr13MoV steel. It is, however, marginally better than German 1.4116 and X50CRMOV15 stainless steel.

FC61 Steel Wear resistance

With daily usage, knife blades are expected to wear and tear, and all types of steel blades bow to the effects of abrasion at some point. For that reason, it is essential to purchase a knife with excellent wear resistance properties, and FC61 knives fall into that category thanks to the high hardness.

Because of the high wear resistance, FC61 blades last for a long time, even with daily usage and frequent sharpening. To improve the lifespan of FC61 steel knives, you can stick to sharpening them with whetstones and avoiding automatic sharpeners.

FC61 Steel Toughness

The toughness of steel can sometimes be described as inversely proportional to its hardness. This means that steel with high hardness offers low toughness. FC61 stainless steel has a hardness of about 61 HRC; however, its toughness level is very high.

The high toughness can be attributed to the high purity of FC61 steel alloy composition, mainly composed of carbon and chromium with minimal impurities. This allows for the formation of fine-grained carbides, which significantly improves toughness and hardness at equal measure.

FC61 stainless steel toughness is better than most stainless steel; Its toughness level is equivalent/comparable to 14C28N steel, AEB-L steel, and LC200N steel. It beats VG10 blade steel, SG2 steel, and even powder Crucibles steels like S45VN and S30V.

FC61 Steel Corrosion resistance

FC61 steel is stainless steel with 13% chromium in its composition, and therefore, it does not rust or stain easily. If you are shopping for a knife in corrosive environments like in the kitchen or areas of high humidity and salty water, FC61 stainless steel knives will not disappoint.

Although the steel is resistant to rust, it can still rust if exposed to corrosive situations. For instance, you cannot leave the blades in water overnight and expect them not to rust. This calls for proper care and maintenance, which involves washing, cleaning, and drying the knives after use. Apply a coat of mineral oil on the blades and remove the sheath for long-term storage for extra protection.

FC61 steel corrosion resistance is comparable to Japanese AUS 8 steel, Nitro V steel, and CPM 154 stainless steel.

Ease of sharpening FC61 Steel

The ease of sharpening a knife blade is directly affected by its hardness. Therefore hard steels like FC61 are challenging to sharpen. Note that this does not mean that the blades will never take a sharp edge after dulling, but it will take you more time and energy to get a sharp edge.

An easier way to get a sharp edge with this steel is to use whetstones. You need to go through the different grades of whetstones for a sharper edge. You can start with a 400 grit to a 1000 grit to a 4000 grit until you get your desired sharpness.

FC61 steel comparison

FC61 steel vs VG10 steel

The main difference between FC61 Steel and VG10 steel is that FC61 steel offers twice the toughness of VG10 blade steel due to its pure alloy composition that greatly improves its toughness over most stainless and non-stainless steel. FC61 blade steel is less likely to break or chip when used on tougher things like cutting bones.

Both FC61 and VG10 knife steels offer good edge retention. However, VG10 steel contains higher amounts of carbon and has vanadium elements in its alloy composition, thus offering higher hardness, edge retention, and wear resistance due to the formation of hard vanadium carbides.

Both FC61 and VG10 are stainless steels; however, Japanese VG10 steel contains a higher amount of chromium elements in its alloy composition hence offering slightly better corrosion resistance.

FC61 steel vs SG2 (FC61 vs MC63)

Henckels uses SG2 Steel under its proprietary name MC63 steel, just like it uses Sandvik 13C26 Steel under its proprietary name FC61 steel. The main difference between FC61 steel and SG2 (Super Gold 2) steel is that FC61 Stainless Steel offers twice the toughness levels of SG2 stainless steel. SG2 stainless steel, on the contrary, offers better edge retention and corrosion compared to FC61 steel.

The high toughness achieved by FC61 Steel is due to its highly pure alloy composition, which lacks other elements like vanadium and has very few impurities in the form of phosphorus or sulfur. The highly pure chemical composition allows the grain of FC61 steel to be extremely fine and thus have better toughness.

SG2 steel, on the other hand, offers better edge retention due to its alloy composition containing high carbon percentage and other elements like vanadium which are responsible for the formation of hard vanadium carbides that are excellent when it comes to edge retention.

SG2 stainless steel also offers slightly better corrosion resistance due to a high amount of chromium elements in its alloy composition than FC61 steel. The difference in corrosion resistance between these two blade steels is not noticeable in daily application.

Is FC61 good knife steel?

Check out this Miyabi 6.5-inch FC61 steel Nakiri knife. Something that makes it stand out from the crowd is the heat treatment techniques used on it. It achieves 61HRC and maintains an exceptionally thin blade close to Usuba level.

- Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

- 【High-End Japanese Steel Chef's Knife】 HOSHANHO chef's knife is made of Japanese high carbon steel 10Cr15CoMoV, 2x of the sharpness and durability of some other “premium” knives, and it owns a very high cost performance! With a hardness of up to 60 HRC, the kitchen knife offers excellent rust resistance, sharpness and durability.

- 【Fashion Matte Blade Design】 The blade has a matte finish, the combination of fashion and durability adds more fun to your cooking. Manufactured using modern technology and traditional techniques, they are ice tempered and heat treated to withstand cold, heat, corrosion and moisture.

- 【Thoughtful Details】 Handle is made of ultra-durable wood, which improves handle curvature, the distinctive sloped bolster shape encourages a proper and safer "pinch grip” , the comfort is absolutely amazing, and you can make the up and forward motion without having to curve your wrist.

- 【Everyday Functionality You'll Love】 Our chef's knife is hand-sharpened to 13 degree on each side, so you can easily do your daily kitchen tasks like chopping, cutting, dicing and chopping vegetables, fruits, meat and cheese with this kitchen knife. Superior sharpness that will impress you with every cut!

- 【Exquisite Gift】 Our chef knife comes with a simple, classic gift box, whether it's Mother's Day, Father's Day, or Thanksgiving, Christmas, New Year's, Easter, Halloween, this HOSHANHO kitchen knife is an elegant and practical gift.

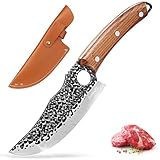

- Razor-Sharp & Durable Edge | Forged from high-carbon stainless steel, this 6-inch chef knife delivers exceptional edge retention and durability. The precisely hand sharpened 12° edge angle creates a razor-sharp edge that glides through meat and vegetables effortlessly, making it a long-lasting core tool for your kitchen.

- Secure Ergonomic Handle | Designed for control and comfort, the handle of this boning knife features a contoured shape and a finger hole for a safe, non-slip grip. Made from carbonized wood, it is highly robust and durable, and resistant to cracking or deformation, ensuring stability during prolonged use.

- Versatile Chef Knife | Master your indoor cooking or become the ultimate outdoor chef. This versatile Viking-style butcher knife excels at prepping ingredients in the kitchen and is equally perfect for camping, BBQs, and processing game, aided by its included durable leather sheath for safe carry.

- Practical & Striking Design | The full-tang blade features a functional hammered texture that reduces friction and prevents food from sticking. This design, combined with a robust full tang and triple-riveted handle, provides ideal balance, superior strength, and a distinct, rugged aesthetic.

- Ready-to-Gift | Beautifully presented with a gift box, this knife makes a remarkable gift for any cooking enthusiast. We stand behind its quality and your satisfaction, offering reliable lifetime support to ensure this DiiHAUZZ chef knife becomes a trusted companion for all your culinary tasks.