CPM S35VN knives are better than D2 knives because they are tougher, corrosion-resistant, and easier to sharpen. D2 knives rust faster than S35VN because D2 steel is semi-stainless steel. However, to choose between S35VN and D2 knives, you must consider how the toughness, edge retention, corrosion resistance, and ease of sharpening the steel affect the intended use of your knife.

In this article, we will look at the characteristics of D2 and S35VN knives side by side to help you decide which one is best for you. Let’s get into it!

Are D2 and S35VN knives the same?

D2 and S35VN are popular steels among knife makers and users. This might trick you into thinking that the knives are the same, but there are significant differences between them.

D2 and S35VN knives are not the same. D2 is semi-stainless steel, and therefore the knives rust faster, while S35VN is stainless steel and the knives offer excellent corrosion resistant. They also differ in toughness, ease of sharpening, and price, but they offer the same level of edge retention.

To help you further understand the differences between D2 and S35VN knives, we will look at their characteristics, pros, and cons in detail in the next section. Here is a table showing the different compositions of D2 steel and S35VN steel.

| Carbon | Chromium | Vanadium | Molybdenum | Niobium | |

|---|---|---|---|---|---|

| D2 Steel | 1.50%-1.60% | 11.50%-12.00% | 0.90%-1.10% | 0.60%-0.90% | 0.00% |

| S35VN Steel | 1.40% | 14.00% | 3.0% | 2.00% | 0.50% |

D2 Knife Characteristics

The D2 knife steel is durable and has decent edge retention. It keeps an edge for a long time, so you do not have to sharpen them after every use. The D2 knife steel is averagely tough and, therefore, can not be used for highly challenging applications like prying.

According to a 1999 research published in the National Library of Canada that looked at the effects of Heat Treatment and Toughness Behavior of D2 Tool Steel for Cutting Blades, D2 steel wear resistance increased with an increase in Rockwell hardness, however, this made it more brittle.

D2 knife steel also offers adequate corrosion resistance, enough to be used in humid and wet conditions but it might rust when left exposed for a longer period as it’s not stainless steel. D2 steel knives are affordable, which makes them a good choice for knife users looking for high-performance knives on a budget. However, the steel is hard to sharpen due to higher wear resistance.

Pros

- Decent edge retention

- Minimal corrosion resistance

- Good balance

- High performance

- Affordable

Cons

- Rust easily when exposed to corrosive environments for a long time

- Hard to sharpen

- Low Toughness

S35VN knife Characteristics

The S35VN knife falls in the high-end category and offers decent toughness, edge retention, and excellent corrosion resistance. Due to the premium quality, the S35VN knife is more expensive than a D2 knife.

According to CATRA (Cutlery & Allied Trades Research Association) testing conducted by Crucible, S35VN was able to achieve better results than 440C steel. The achieved value has been similar to other CATRA testing values achieved by D2, there is no significant difference in edge retention between S35VN and D2.

S35VN steel is a CPM steel, the CPM production process produces homogenous high-quality steel. This enables CPM S35VN to be suitable for pocket knives, kitchen knives, and other bigger blades, unlike D2 steel which is not tough enough for bigger blades.

Pros

- Decent edge retention

- Good corrosion resistance

- Tough

- Excellent performance

- Easy to sharpen

- Made of premium-grade steel

Cons

- Pricey

- SK5 Steel Durability: Made from industrial-grade SK5 high carbon steel, these heavy duty utility blades provide exceptional hardness and edge retention. Compared to standard carbon steel, SK5 offers improved wear resistance and extended life span, ensuring fewer blade changes and higher efficiency during cutting tasks. Whether you're working on renovation projects, packaging, or construction sites, these blades can handle tough materials like carpet, drywall, rubber, and rope with ease

- Standard Size Fit: This utility knife blades 100 pack is crafted to meet universal blade specifications, ensuring a perfect fit with most retractable utility knives, folding knives, and box cutters. Whether you're replacing utility knife blades for everyday tasks or switching out box cutter blades on the job, these standard-size blades deliver reliable compatibility and performance you can count on across various tools and scenarios

- Razor Sharp Edge: Our razor blades for utility knife are precision-honed to deliver ultra-sharp, clean cuts every time. Engineered with a refined edge angle, these blades slice effortlessly through thick cardboard, leather, carpet, vinyl, linoleum, soft metals, and more. The sharpness reduces drag, improves control, and minimizes hand fatigue—making it the ideal choice for DIYers, contractors, or warehouse professionals

- Safe Storage Box: Each set comes with a compact and durable utility blade storage box that protects blades from dust, moisture, and accidental contact. The slide-out design allows safe, one-at-a-time access to blades while keeping unused blades neatly organized. Whether stored in a toolbox, desk drawer, or tool belt, this box keeps your workspace safer and your workflow smoother

- Trusted by Pros & DIYers: These replacement blades for utility knife are built with Jetmore’s commitment to precision and durability. Whether you're a professional in construction, a warehouse operator, a DIY hobbyist, or simply handling everyday home repairs, Jetmore delivers blades you can trust. We stand behind our quality—so you can cut with confidence, knowing your tools won’t let you down

- Notice: Be sure to watch our HOW-TO video before using it. It can help you slide the utility blade out quickly and easily

- Super Versatility: It is made entirely according to standard utility knife blades and fits most standard & fixed utility knives perfectly

- Affordable: Includes 100-pack replacement blades and they come in a well-built case for safe storage and disposal. Each blade is rigorously tested and we firmly believe this is a great deal

- Durability: WORKPRO utility knife blades are made from SK5 steel, which is of high quality and durability

- Sharp: The knife blades are highly sharp and cut through lots of materials easily and without hesitation. Ideal for cutting cardboard, leather, linoleum, rope, soft metal, etc

- Heavy duty utility blade for general cutting, trimming, and scraping of a variety of materials

- Precision-honed edge for consistent and long cutting life

- Fits most standard utility knives

- 100 pack

Difference Between D2 and S35VN knives

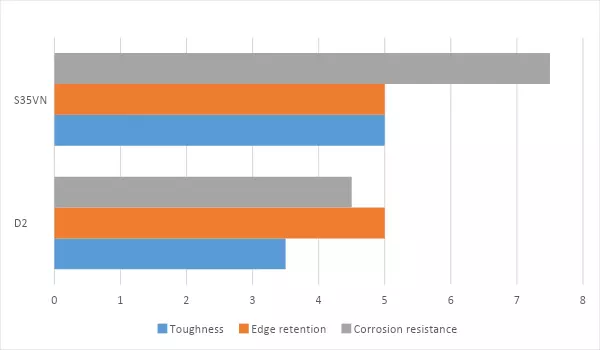

| D2 | S35VN | |

|---|---|---|

| Toughness | 3.5 | 5 |

| Edge retention | 5 | 5 |

| Corrosion resistance | 4.5 | 7.5 |

| Ease of sharpening | Hard | Easy |

To choose between D2 and S35VN knives, you must consider their toughness, corrosion resistance, and ease of sharpening. The best knife for you among the two should be able to meet all your needs, and the performance is determined by its features.

Toughness

D2 offers low toughness because it is hard steel. The hardness is attributed to its composition’s high amounts of carbon and vanadium. The blades’ toughness is low, but it is not the worst on the market. It can withstand demanding applications like light chopping and light batoning without breaking, chipping, or cracking.

According to Crucible Industry, the composition of S35VN is more balanced by Substituting part of niobium carbides with vanadium carbides. CPM S35VN knife blades are thus tougher than D2 knife blades as the carbides promote better resistance to edge chipping.

Corrosion Resistance

D2 steel knives do not offer the best corrosion resistance because they are semi-stainless steel. They contain 12% chromium which is less than 13% required to make it stainless steel. D2 knives can fight corrosion, but they rust faster when overly exposed to corrosive conditions.

S35VN knives offer better corrosion resistance than D2 knives. S35VN steel knives contain enough chromium to qualify as stainless steel, so the knives are highly resistant to corrosion. They do not easily stain and rust; therefore, you can use them in areas of high humidity and salt water without worries.

However, most steel can rust without proper care; therefore, ensure to wash and dry S35VN knives after every use to keep rust at bay.

Ease of Sharpening

D2 knives are not easy to sharpen because it is hard steel. S35VN knives are also not easy to sharpen, but they are easier to sharpen compared to D2 knives and other premium steels with the same hardness. You will be able to get a razor-sharp edge with S35VN knives with simple sharpening tools and basic knife sharpening skills.

Price

Because it is high-grade steel, S35VN makes expensive premium knives. On the other hand, D2 is affordable steel used to make everyday knives for knife users on a budget.

What Makes A Good Quality Knife?

The definition of a good quality knife differs among knife users. A knife is of good quality to you if it performs the intended purpose without fail. However, there are general qualities that make a good quality knife.

A good quality knife should be sharp and stay sharp for long, be lightweight, and have an ergonomic handle.

Sharpness- a quality knife should be able to achieve an ultra-sharp edge that cuts through materials and ingredients with ease.

Hold sharpness for long- a knife that does not become dull faster is easy to maintain and is more durable.

Lightweight- a lightweight knife is easy to use and does not leave your arms and hands exhausted after prolonged use.

Ergonomic handle- an ergonomic handle gives you control and prevents accidents.

Final Thoughts

CPM-S35VN is a premium steel, it is better than D2 steel; It has better toughness, corrosion resistance, and ease of sharpening. Both S35VN and D2 exhibit the same level of edge retention. If price isn’t an issue and you want a premium knife, go with S35VN, If you want something cheaper, go with D2.