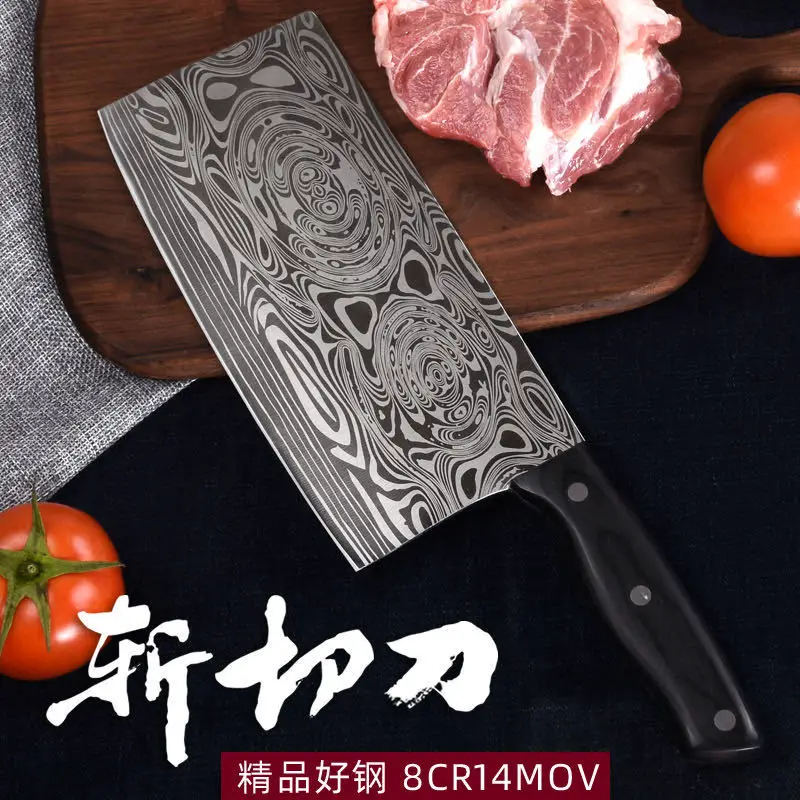

What is 8Cr14MoV Steel?

8Cr14MoV Steel knives will not offer excellent performance like high-end steel knives, but they are good for the price. Do not despise the performance of these knives because of the low price compared to the price tag of premium steels.

Due to the high amount of chromium elements in its composition, 8Cr14MoV is stainless steel, hence offering good corrosion resistance.

Apart from knife manufacturing, this steel is also used in other industries to make medical instruments, cutting tools, and cutting edge die.

8Cr14MoV Steel Composition

- Carbon C 0.75%: Increases the edge retention, hardness and tensile strength. It also improves steel resistance to wear, abrasion and corrosion.

- Chromium Cr 14.00%: Chromium Increases hardness, tensile strength and toughness of the blade by forming chromium carbide. The higher than 13% Cr is what makes 8Cr14MoV “stainless”

- Molybdenum Mo 0.25%: It improves machinability and hardening property.

- Manganese Mn: 0.50%: improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

- Vanadium V 0.15%: Increase wear resistance and toughness, it also improves corrosion resistance.

- Cobalt Co 2.50% Improves hardness of the blade as it increases the martensitic transformation temperature of the alloy, it also increases corrosion resistance of steel.

- Sulphur 0.015%: Increases machinability of steel but can reduce toughness in large amounts.

- Silicon 0.50%: Improves grain structure for better hardness, however like Manganese it can increase brittleness.

- Tungsten W 3.00% Improves wear resistance and hardness, mostly added to tool steel.

- Phosphorous P 0.035%: Improves the hardness but is regarded as an impurity.

Properties of 8Cr14MoV Steel

8Cr14MoV Steel Hardness

8Cr14MoV stainless steel hardness is 58-59 HRC as per the Rockwell hardness scale. This hardness level is high enough to give its blades good edge retention, sharpness, and wear resistance.

Also, the hardness of 8Cr14MoV blades differ depending on the process used by the manufacturer.

8Cr14MoV Steel Edge retention

8Cr14MoV stainless steel retains a sharp edge for a long time, which is one of the properties that make knives made of this steel stand out considering their low prices.

With the high hardness level attributed to the Carbon and chromium in its composition, blades made of this steel stay sharp for a long time, even with frequent use.

8Cr14MoV Steel Wear resistance

The decent amounts of Carbon, chromium, and vanadium in this steel give it higher wear resistance than other low-budget steel types.

Blades made from this steel can withstand abrasion and rough applications. Therefore, you can trust 8Cr14MoV stainless steel knives to serve you for a long time.

8Cr14MoV Toughness

The toughness of steel is key in determining how it reacts to tough applications, which would lead to chipping or breaking. 8Cr14MoV stainless steel has decent toughness thanks to the chromium and molybdenum in its composition.

8Cr14MoV steel knives can withstand moderate abuse; they will serve you best if you use them for normal cutting jobs. If you expose them to batoning and other very tough cutting jobs, they will break and chip in no time.

8Cr14MoV Steel Corrosion resistance

Being stainless steel with more than 16% Chromium, 8Cr14MoV steel offers excellent corrosion resistance. You can use blades made from this steel in humid, wet, and marine environments without worrying about stains or rust.

It is because of this property that this steel is preferred in making kitchen and EDC knives. Also, to boost its corrosion resistance, everyday care and maintenance is essential. Wash and dry the blades after use.

Ease of Sharpening 8Cr14Mov steel

8Cr14MoV is hard steel, but not very hard to make it difficult to sharpen. You can get a sharp edge with this steel quickly using simple sharpening tools.

If you are on the market looking for a low-budget knife, which does not require frequent sharpening and is easy to sharpen, the varieties of 8Cr14MoV will never disappoint you.

Best 8cr14mov Steel Knives

- Premium Steel Construction - The steel rod is made of carbon steel and plated with nickel-chrome; the fine surface of the steel rod prevents the cutting edge from damage when sharpening.

- Versatile Compatibility - Our knife sharpening steel rod is for all types of knives, including kitchen, household, sporting and pocketknives; sharpens standard and serrated edge knives. Restores dull knives to razor-sharp perfection with ease.

- Ergonomic Non-Slip Grip - Easy to use, with an ergonomic handle that fits your hand, be it right or left. The slip-resistant rubber bottom makes the rod easy to handle and firmly stays in place during use.

- Hanging Loop for Storage - Convenient design for easy access and space-saving storage.

- Effortless Maintenance - Use a non-woven cloth soaked with cooking oil to wipe the body and dry it. If washed with water, be sure to wipe the rod dry completely and hang in a cool place to air-dry. Do not put the sharpener into the dishwasher.

- 12" Sharpening Steel maintains the edge on knives and extends the life of your cutlery with regular use.

- Steel rod is made of carbon steel and plated with nickel-chrome.

- Ergonomic, easy-to-grip polypropylene handle with hanging hole.

- Wipe clean with a damp cloth.

- Normally used for Dull Knifes, Best Choice for chef using.

- KEEPS KNIVES RAZOR-SHARP: Maintain knife edges between professional sharpenings.

- EFFORTLESS MAINTENANCE: Designed for regular use—hone your kitchen or BBQ knives every other time for peak performance.

- COMFORTABLE & SAFE GRIP: Smooth polypropylene handle offers a secure hold while sharpening.

- VERSATILE SHARPENING TOOL: Ideal for chef knives, BBQ tools, and everyday kitchen cutlery.

- CONFIDENCE FOR LIFE: Backed by a lifetime guarantee for long-term reliability and satisfaction.

8Cr14MoV Steel Vs. other knife steels

8Cr14MoV vs D2 Steel

The major difference between 8Cr14MoV steel and D2 steel is that 8Cr14MoV is stainless steel while D2 steel is regarded as semi-stainless steel. 8Cr14MoV thus majorly outshines D2 steel in corrosion and stain resistance.

D2 steel on the other hand is better than 8Cr14MoV steel in edge retention and wear resistance, it does this as it contains a higher percentage of carbon in its alloy composition.

8Cr14MoV steel is softer steel than D2 steel offers better toughness and is less likely to chip or break under tough applications. The higher toughness of 8Cr14MoV steel is comparable to AUS 8 steel and Vanadis 8 Steel.

8Cr14MoV vs 8Cr13MoV

8Cr14MoV and 8Cr13MoV are Chinese made steel almost identical in chemical composition and have same hardness, sharpness, toughness, and wear resistance. However, 8Cr14MoV contains more chromium, hence it has better corrosion resistance than 8Cr13MoV steel.

8Cr14MoV Steel vs AUS 8

8Cr14MoV is Chinese steel while AUS 8 steel is Japanese steel, hence considered high-end steel with more Carbon. More Carbon translates to better in edge retention, wear resistance, and hardness.

However, they have the same level of toughness. In terms of corrosion resistance, The AUS 8 steel has more Chromium elements in its alloy composition meaning it will offer better corrosion resistance.

Is 8Cr14MoV Steel good knife Steel?

The low pricing might lure you into thinking that 8Cr14MoV knives are low quality, but you will be surprised that they will serve you efficiently for a long time.

However, do not subject them to the pressure and tough application as you would knives made from high-end steels.

Future Developments and Alternatives

Advancements in Stainless Steels

Stainless steels, known for their corrosion resistance, are continuously being improved and refined. New formulations are being introduced that offer enhanced properties compared to traditional steels. For example, nitrogen-enriched stainless steels like VG-10 and N690Co provide increased hardness and edge retention, making them potential alternatives to 8Cr14MoV.

Powder Metallurgy (PM) Steels

Powder metallurgy is an advanced manufacturing technique that involves the consolidation of powdered steel particles under high pressure and temperature. This process enables the creation of steels with exceptional performance characteristics. PM steels such as S30V, S35VN, and M390 exhibit superior edge retention, wear resistance, and toughness, making them highly sought-after alternatives to 8Cr14MoV.

High-Speed Steels (HSS)

High-speed steels are known for their exceptional heat resistance and ability to retain hardness even at high temperatures. While primarily used in cutting tools, some HSS grades like M2 and CPM 3V have found applications in knives. These steels offer excellent wear resistance and edge retention, making them attractive alternatives for those seeking enhanced performance.

Composite Blade Materials

Composite blade materials, such as laminated steels or Damascus steel, combine multiple layers of different metals to leverage their individual properties. By incorporating a high-performance steel as the core layer and surrounding it with more corrosion-resistant or aesthetically appealing metals, knife makers can create blades that offer both performance and visual appeal.

Non-Steel Materials

The quest for alternative materials has led to the emergence of non-steel options for knife blades. Ceramic blades, for instance, provide exceptional hardness and corrosion resistance, although they are more brittle compared to steel. Another intriguing option is the use of advanced synthetic materials, such as high-performance polymers or carbon fiber composites, which offer lightweight construction and corrosion resistance.

Maintenance and Care

- Cleaning: After each use, it’s important to clean your 8Cr14MoV knife thoroughly to remove any dirt, debris, or moisture that may have accumulated. Follow these steps for effective cleaning:

- Rinse the blade under warm water to remove surface contaminants.

- Use a mild dishwashing soap and a soft-bristled brush or cloth to gently scrub the blade and handle.

- Pay attention to the pivot area, handle scales, and any other hard-to-reach areas.

- Rinse the knife again under warm water to remove any soap residue.

- Thoroughly dry the blade with a clean cloth or paper towel to prevent moisture-related issues.

- Lubrication: To maintain smooth opening and closing action, as well as prevent corrosion, it is recommended to lubricate your 8Cr14MoV knife periodically. Follow these steps for proper lubrication:

- Apply a small amount of lubricant, such as a quality knife oil or light machine oil, to the pivot area and any other moving parts.

- Open and close the knife several times to distribute the lubricant evenly.

- Wipe away any excess oil to prevent attracting dust and debris.

- Storage: Proper storage is essential to protect your 8Cr14MoV knife from damage and maintain its condition. Consider the following storage recommendations:

- Store your knife in a dry environment to minimize the risk of corrosion.

- If possible, store the knife in a sheath, blade cover, or knife pouch to protect it from physical damage and to prevent accidental cuts.

- Avoid storing your knife in prolonged contact with other metals, as this can lead to galvanic corrosion.

- Sharpening: Regular sharpening is necessary to maintain the cutting performance of your 8Cr14MoV knife. Follow these tips for sharpening:

- Use a sharpening stone or a sharpening system designed for knives.

- Follow the manufacturer’s instructions for the specific sharpening tool you are using.

- Maintain a consistent angle while sharpening to achieve an even and sharp edge.

- Start with a coarse grit stone and progressively move to finer grits for a polished edge.

- After sharpening, remove any burrs by gently stroking the blade on a leather strop or honing rod.

- General Tips:

- Avoid using your 8Cr14MoV knife on hard surfaces or for prying tasks to prevent blade damage.

- Never put your knife in a dishwasher, as the harsh detergents and high heat can cause damage to both the blade and handle materials.

- Regularly inspect your knife for any signs of wear, loose components, or damage. If detected, address the issues promptly to prevent further damage.

Bestseller No. 1

Astercook Knife Set, 13 Pieces Kitchen Knives Set with Healthy Anti-Rust Coating, Dishwasher Safe, Stainless Steel Chef Knife Sets with 6 Blade Guards, Perfect Valentine's Day Gifts for Kitchen - Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

Bestseller No. 2

Dealusy 360 Count Extra Heavy Duty Clear Plastic Knives Disposable, BPA-Free, Heat Resistant, Solid and Durable Disposable Knives Bulk, Premium Plastic Knives heavy duty for Party Supply - 【Premium Material】: Dealusy clear plastic knives heavy duty are made of food grade polystyrene, total BPA free and toxin free for your healthy meals.

- 【Extra Heavy Duty】: Each plastic knife weights 5.9g, our heavy duty plastic knives disposable with edge thickened design won’t bend easily.

- 【Heat Resistant】: These disposable knives can withstand a high temperature, ideal for hot and cold food.

- 【360 Value Pack】: This disposable knives bulk contains 360 count high quality clear plastic knives, perfect for your everyday use or serving a wedding, panic, party etc.

- 【Disposable or Resuse】: These strudy and durable knives are suitable for disposable use, or you can wash to reuse.

Bestseller No. 3

Dalstrong Chef Knife - 8 inch - The FLASH™ Edition - German X50CRMOV15 Stainless Steel - Gold Titanium Nitride - G10 Handle - Full Tang - Premium Leather Sheath - Collection Edition w/Pin - Lightning-Fast Precision Meets Culinary Power: Inspired by The Scarlet Speedster, this officially licensed The Flash Edition chef knife slices with blistering speed and control. The ultra-sharp 8-12° double-bevel edge glides through prep with zero drag, delivering searing precision and friction-free performance like a Super Hero.

- Forged From Premium German Steel: Crafted from high-performance X50CRMOV15 stainless steel, trusted by chefs worldwide for its balance of sharpness, strength, and durability. With a Rockwell hardness of 54-56 HRC, this blade resists chipping and corrosion, holds its edge under heavy use, and sharpens easily for a lifetime of reliable performance.

- Titanium Nitride Coating for Zero Drag: Finished with a striking gold Titanium Nitride (TiN) coating, this blade isn’t just built to shine — it’s built to zoom. TiN reduces drag and friction for faster, smoother slicing and adds a hard, wear-resistant layer that shrugs off corrosion and everyday wear, keeping your edge sharper, slicker, and longer-lasting.

- Collector-Worthy Detail, Pro-Grade Design: DC The Flash artwork is laser-etched into the mirror-polished blade, celebrating DC’s iconic Super Hero while enhancing slicing performance by reducing food stick. A G10 handle with copper spacer ensures superior balance, comfort, and control, while full-tang construction locks in strength from heel to tip.

- Includes Premium Leather Sheath & Collector Pin: Protect your blade in storage or on the go with a genuine stamped leather sheath featuring official The Flash insignia. Every knife includes an exclusive collector’s pin and Dalstrong’s lifetime warranty plus a 70-day money-back guarantee, because your investment should be protected.

- Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

- 【Premium Material】: Dealusy clear plastic knives heavy duty are made of food grade polystyrene, total BPA free and toxin free for your healthy meals.

- 【Extra Heavy Duty】: Each plastic knife weights 5.9g, our heavy duty plastic knives disposable with edge thickened design won’t bend easily.

- 【Heat Resistant】: These disposable knives can withstand a high temperature, ideal for hot and cold food.

- 【360 Value Pack】: This disposable knives bulk contains 360 count high quality clear plastic knives, perfect for your everyday use or serving a wedding, panic, party etc.

- 【Disposable or Resuse】: These strudy and durable knives are suitable for disposable use, or you can wash to reuse.

- Lightning-Fast Precision Meets Culinary Power: Inspired by The Scarlet Speedster, this officially licensed The Flash Edition chef knife slices with blistering speed and control. The ultra-sharp 8-12° double-bevel edge glides through prep with zero drag, delivering searing precision and friction-free performance like a Super Hero.

- Forged From Premium German Steel: Crafted from high-performance X50CRMOV15 stainless steel, trusted by chefs worldwide for its balance of sharpness, strength, and durability. With a Rockwell hardness of 54-56 HRC, this blade resists chipping and corrosion, holds its edge under heavy use, and sharpens easily for a lifetime of reliable performance.

- Titanium Nitride Coating for Zero Drag: Finished with a striking gold Titanium Nitride (TiN) coating, this blade isn’t just built to shine — it’s built to zoom. TiN reduces drag and friction for faster, smoother slicing and adds a hard, wear-resistant layer that shrugs off corrosion and everyday wear, keeping your edge sharper, slicker, and longer-lasting.

- Collector-Worthy Detail, Pro-Grade Design: DC The Flash artwork is laser-etched into the mirror-polished blade, celebrating DC’s iconic Super Hero while enhancing slicing performance by reducing food stick. A G10 handle with copper spacer ensures superior balance, comfort, and control, while full-tang construction locks in strength from heel to tip.

- Includes Premium Leather Sheath & Collector Pin: Protect your blade in storage or on the go with a genuine stamped leather sheath featuring official The Flash insignia. Every knife includes an exclusive collector’s pin and Dalstrong’s lifetime warranty plus a 70-day money-back guarantee, because your investment should be protected.