What is H2 Steel?

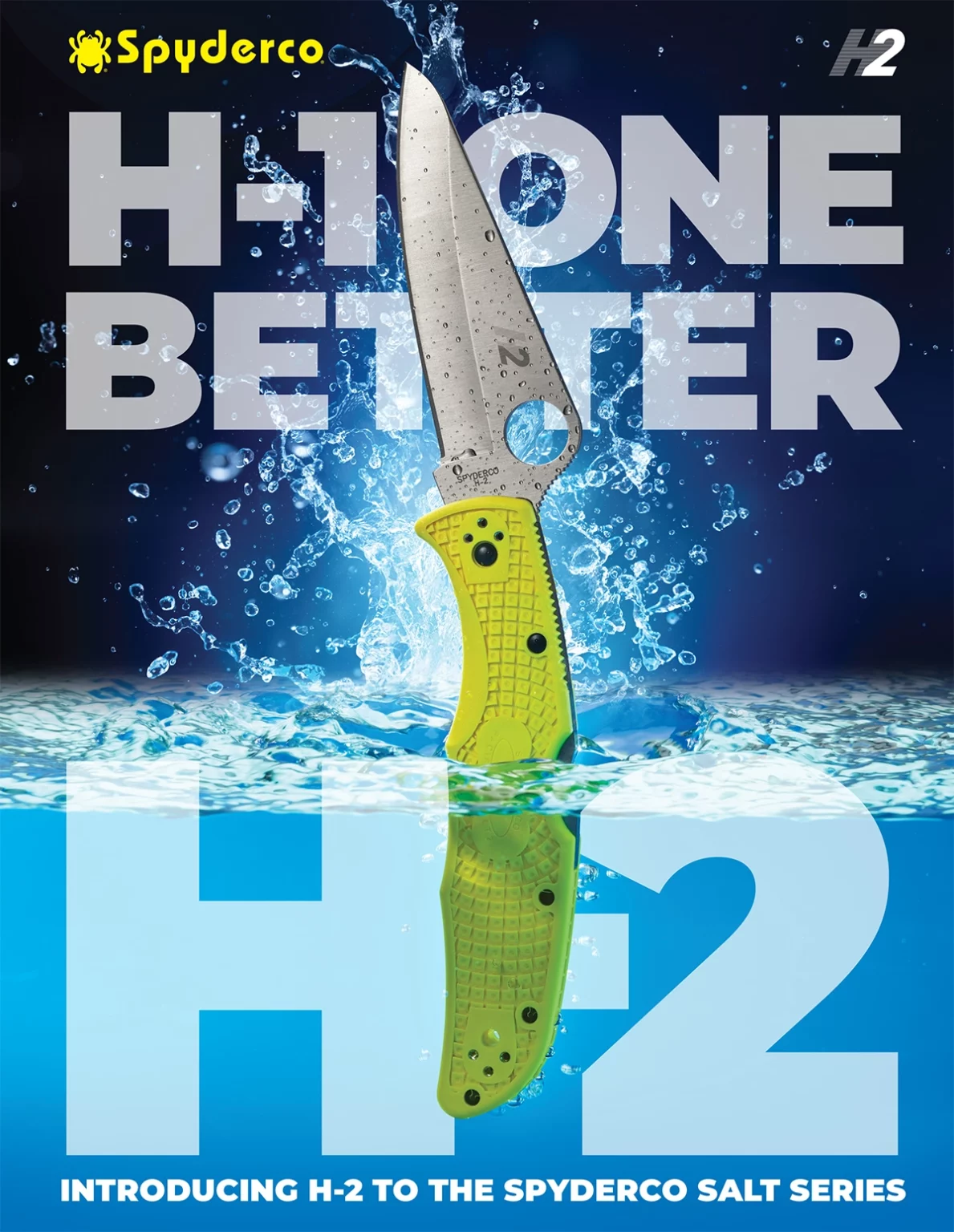

Although it is a huge loss to the steel industry, there is a positive side because Spyderco, in partnership with other steel manufacturing partners in Japan, has developed H2 steel, which offers better corrosion resistance than H1.

Spyderco H2 steel takes the same chemical composition and manufacturing process as H1, but it is further refined and thus offers better qualities. For instance, H2 contains less carbon than H1, enhancing its corrosion resistance. It contains more molybdenum and, therefore, better hardness, toughness, machinability, and corrosion resistance.

H2 Steel Composition

- Carbon – reduced from 0.15 to 0.09 percent: Carbon in steel promotes the formation of carbides and increases the steel’s vulnerability to corrosion. Reducing the amount of carbon in H-2 further reduces this risk and therefore helps enhance its corrosion resistance.

- Chromium – reduced from 14.00-16.00 to 13.73 percent: Chromium in solution in a steel increases its corrosion resistance by allowing it to form a protective chromium oxide layer on the surface. The slight reduction of chromium was possible due to the reduction in carbon, but still ensures a high amount of chromium in solution.

- Copper – 0.17 percent added: The addition of copper in austenitic steel enhances its precipitation hardening properties and increases its corrosion resistance, especially in seawater environments and against exposure to sulfuric acid.

- Manganese – reduced from 2.00 to 0.32 percent: Manganese improves the hot-working properties of steel and increases its strength, toughness and hardenability. Like nickel, it is also an austenite-forming element. The reduction in manganese is largely balanced by H-2’s increase in nickel and its substantial increase in molybdenum.

- Molybdenum – increased from 0.50-1.50 to 2.24 percent: Molybdenum increases a steel’s strength, hardness, hardenability, and toughness. It also improves its machinability and resistance to corrosion. When added to chromium-nickel austenitic steels, molybdenum improves resistance to pitting and crevice corrosion, particularly in chlorides and environments containing sulfur—like seawater.

- Nickel – increased from 6.00-8.00 to 8.25 percent: Nickel’s ability to form austenite gives austenitic steels great toughness and strength. It also greatly improves resistance to oxidation and corrosion.

- Nitrogen – reduced from 0.10 to 0.06 percent: Like nickel, nitrogen is an austenite-forming element. It increases the austenite stability of stainless steel, improves its yield strength, and enhances its resistance to pitting corrosion. The adjustment to H-2’s nitrogen content is balanced by its increase in nickel content.

- Phosphorous – reduced from 0.04 to 0.027 percent: Phosphorus improves machinability and increases the strength of austenitic steels; however, it can also have a detrimental effect on corrosion resistance. Reducing H-2’s phosphorous content helps enhance its corrosion-resistant qualities.

- Silicon – reduced from 3.00-4.50 to 2.63 percent: Silicon is the most common alloying element in steel. It helps purify the iron ore during the smelting process by deoxidizing it and removing impurities. The fine-tuning of the volume of this element is based on the needs of the smelting process.

- Sulfur – reduced from 0.03 to 0.001 percent: Small amounts of sulfur improve a steel’s machinability; however, like phosphorous, it is detrimental to corrosion resistance. Reducing H-2’s sulfur content further contributes to its corrosion-resistant properties.

H2 Steel alloy composition source Spyderco.com

Properties of H2 steel

H2 Steel Hardness

H2 is expected to have the same level or even higher hardness than H1, but its hardness is lower by 1 or 2 RC because of the reduced silicone elements in its composition. H1 can reach a hardness of 57-58 HRC. Due to the reduction of silicone, H2 steel can reach a Rockwell hardness of 55-57HRC, which is a decent hardness.

According to Spyderco H2 steel is austenitic steel that uses age hardening, which is the use of controlled heat to increase the tensile and yield strength of the steel. Like H1 steel, H2 steel hardening involves the transformation of austenite to hard martensite through intense rolling and coldworking process.

H2 Steel Toughness

The toughness of steel increases with reduced hardness. 57 HRC is considered low hardness, and therefore H2 offers great toughness. Like H1, H2 does not contain brittle carbides, a property that enhances its toughness. H2 steel does not break, chip, or crack when used for tough applications because of its high toughness.

H2 stainless steel also contains soft, ductile ferrite and the lack of brittle carbides which heavily increases its impact toughness. H2 stainless steel knives are thus expected to offer very high toughness, better than most knife steels especially stainless steel.

H2 Steel Wear resistance

The wear resistance of steel is directly related to its hardness and carbides in its alloy composition. So, H2 steel has low wear resistance since it has low hardness. The lack of carbides contributes to excellent toughness but reduces the wear resistance of H2.

Because of the poor wear resistance, H2 steel knives cannot withstand constant abrasion and wear, and therefore they will not serve you for a long time. H2 blades will easily deform and lose shape with frequent usage and sharpening.

H2 Steel Edge retention

The edge retention ability of H2 stainless steel is low because of its low hardness and low wear resistance. With frequent use, the H2 blades become blunt very fast. If you plan to use H2 knives for outdoor use frequently, it would be best to carry a sharpening tool.

H2 stainless steel contains very little amount of carbide if any. Carbide is highly responsible for wear resistance and edge retention. Carbide formation was further reduced in H2 stainless steel to avoid the risk of corrosion and rusting as carbides increase the vulnerability of steel to rust.

H2 Steel Corrosion resistance

H2 steel contains less chromium but more molybdenum than H1, which gives it more corrosion resistance abilities. H2 steel is ideal for the manufacturer of knives to be used in highly corrosive environments like in the kitchen or areas with salty water.

With low carbon elements, almost all the chromium in its composition is used to fight corrosion instead of forming hard chromium carbides. The corrosion resistance is increased by the addition of molybdenum in the composition.

H1 corrosion resistance was estimated to be in the range of Vanax stainless steel. With improved corrosion resistance of H2 stainless steel, we can conclude it is higher than that of Vanax hence the best in knife steel.

Ease of sharpening H2 Steel

H2 steel falls in the soft steel category, making it very easy to sharpen. A simple sharpening tool will give you a razor-sharp edge very fast. H2 is the perfect steel to practice and learn sharpening with if you are a beginner in knife sharpening. However, blades of H2 steel become dull after a few cuts, which means frequent sharpening.

Related – 6 New Knife Steels To Look Out For

H2 comparison

H2 vs. VG10

VG10 is popular knife steel and offers a good balance of all its properties. It contains more carbon in its composition and offers better edge retention than H2. On the other hand, H2 beats VG10 in toughness, and corrosion resistance and is easier to sharpen.

H2 steel vs. LC200N

LC200N is high-end steel that offers almost the same level of corrosion resistance as H2. It also performs satisfactorily in toughness and ease of sharpening, but H2 performs better. LC200N /Cronidur 30 offers better edge retention and wear resistance than H2 due to the presence of carbides that H2 lacks.

H2 vs S30V

S30V is a premium steel with an all-around performance, but it cannot beat H2 in corrosion resistance, toughness, and ease of sharpening. When it comes to edge retention and wear resistance, S30V takes the lead due to the presence of a large number of hard carbides like Vanadium carbides and chromium carbides.

You can use S30V knives every day for months without sharpening them, which can never happen with H2 blades. However, H2 knives will outperform S30V knives in salty and highly corrosive environments.

H2 steel vs H1 Steel

Spyderco H2 steel is an improvement of H1 steel and thus offers better performance in terms of corrosion resistance. H2 stainless steel for instance reduces the amount of chromium content but increases the molybdenum content for better corrosion and rust resistance.

H2 steel also contains an additional amount of Nickel and a reduction of silicon thus greatly improving its stainless performance. There is not much improvement in terms of edge retention and toughness as both steels contain relatively the same amount or very little carbides.

H2 steel is expected to maintain the same toughness level as H1 steel or offer even better toughness due to the reduction of Rockwell hardness. Reduction of chances of forming carbides in H2 steel may give H2 blade steel a slight bump in toughness over H1 steel.

Is H2 good knife steel?

There is no good or bad steel; it all depends on the properties of knives that matter to you. Steel that offers a more balanced approach in terms of edge retention, corrosion resistance and toughness like S30V or S35VN will be good for an EDC intended for normal use.