What Is D2 Steel?

D2 steel is a die type of steel, part of the broader category of carbon steels, evidenced by the letter D in its name. D2 is an air-hardening, high carbon steel, high chromium steel and has one of the highest levels of carbon among tool steel alloys.

Is D2 Steel Stainless?

However, D2 steel is not categorized as stainless steel because it has a chromium composition of 11.5 to 12%, which does not meet the 13% chromium content to make it stainless. Because of this, D2 tool steel is referred to as semi-stainless tool steel, though it is still considered corrosion resistant to some extent.

In addition, this steel belongs to the cold-work category of steel because it is shaped after cooling, usually at the ambient temperature.

D2 tool steel also experiences low distortion and has better machining quality compared to other high chromium steel due to its carbide forming elements.

AISI D2 is made following the air quenching process, giving it the ability to achieve and retain its hardness at different temperatures.

D2 Steel Composition

Carbon C 1.50%: Increases the edge retention, hardness, and tensile strength. It also improves steel resistance to wear, abrasion, and corrosion.

Chromium Cr 12.0%: the formation of Chromium carbide Increases the hardness, tensile strength, and corrosion resistance of the blade.

Molybdenum Mo 0.80%: It improves machinability and gives D2 steel the characteristic air hardening property.

Vanadium V 1.10%: Increase wear resistance and toughness, it also improves corrosion resistance. Vanadium acts by improving the grain structure and the carbide structure of the steel.

Manganese Mn 0.45%: improves the strength and hardness of steel. When the steel is heat-treated, hardenability is improved with increased manganese.

Silicon Si 0.40%: Increases strength and heat resistance.

Phosphorus P 0.03%: Improves machinability and hardness.

Sulfur S 0.03%: Improves machinability.

Properties Of D2 Steel

D2 Steel Hardness

According to the Rockwell C hardness scale, D2 has a Rockwell hardness of 60 HRC but may reach up to 64HRC depending on the tempering temperature. With such hardness, a blade made from this steel can hold edges for a long time in addition to admirable wear resistance.

D2 Wear Resistance

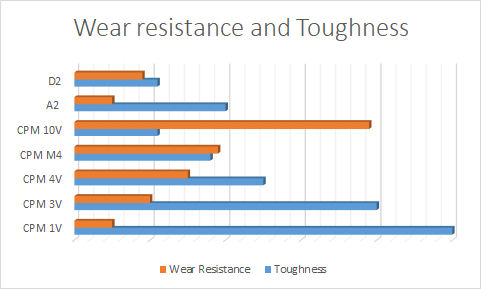

D2 steel is known for its excellent wear resistance. If you ask around knife users, they will tell you that D2 takes the crown in wear resistance.

This feature is attributed to the good mix of chromium, carbon, vanadium, and manganese in its composition. This property makes the D2 knives the best for abrasive cutting compared to other types of steel on the market.

Wear resistance and Toughness of D2 steel vs other steels

D2 Steel Edge Retention

As always, steel with high hardness makes blades with good edge retention, which is true with D2 tool steel. The edge retention of D2 is better than that of 154CM, grade 440C and it is similar to that of CPM 3V steel but significantly worse than that of S35VN, S30V, and M390 steels.

The high carbon levels in its composition make this possible. If you are on the market for a knife that will not require frequent sharpening, look into the options made from AISI D2 steel.

D2 Steel Toughness

You rarely get hardness and toughness from the same steel, and this is the case with D2. Since D2 has high hardness, its toughness is low. The low toughness is attributed to the large carbides that negatively affect its toughness.

While there are other knife steels with better toughness than D2, it offers enough hardness to handle light chopping without breaking. The toughness of D2 knife steel is similar to that of Z-Max steel, 154CM, BD1N, and Bohler N690 steel.

Despite its lower toughness, D2 steel is still used in some combat knives due to its high hardness and edge retention.

However, consider tougher steels like X50CrMoV15 or CPM M4** steel** if you are looking for a knife to handle tough applications like batoning and chopping. Low alloy tool steels like 1084 steel will be better for knives that require higher toughness.

D2 Steel Sharpening

Sharpening D2 steel is a challenging task considering that it is hard steel and high on abrasion and wear resistance. It will take you more effort and time to achieve an ultra-sharp edge with D2, but this is compensated with long edge retention, reducing the frequency of sharpening.

Inexperienced knife sharpeners struggle to get an edge from D2 knives, but it is doable, especially using diamond or ceramic sharpeners on the blade. Whetstones also work well going through the different grits.

D2 Steel Corrosion Resistance

The fact that D2 is not stainless steel discourages many people from buying it because of the assumption that it rusts. To clear the air, let us answer a very common question, does D2 steel blade rust? The honest answer will be yes; it does rust but not as easy as many knife users assume.

Unlike martensitic stainless steel, which is known for its excellent corrosion resistance, D2 steel requires more maintenance to prevent rust. While it does not contain the required chromium levels to make it stainless steel, its 12% chromium content is enough to resist corrosion with good care and maintenance. You cannot keep your D2 knives dirty and wet and expect them not to rust, it requires regular clean-up after use.

Applications of D2 Steel

D2 steel is a versatile tool steel that finds its way into a myriad of applications across different industries, thanks to its exceptional wear resistance, high hardness, and good corrosion resistance. Here are some common uses:

Cutting Tools: D2 steel is a favorite for making cutting tools such as knives, scissors, and shears. Its high hardness and wear resistance ensure that these tools maintain their sharpness and effectiveness over prolonged use.

Wear Parts: The high wear resistance of D2 steel makes it ideal for manufacturing wear parts like gears, bushings, and bearings. These components benefit from D2’s ability to withstand heavy loads and resist abrasion.

High-Temperature Applications: D2 steel’s high heat resistance and ability to maintain hardness at elevated temperatures make it suitable for high-temperature applications such as heat treatment and forging.

Aerospace Industry: In the aerospace sector, D2 steel is valued for its high strength, low weight, and good corrosion resistance, making it a reliable material for various components.

- Multifunctional Knife Storage : This Pocket Knife Holder Can Hold 12 Knives, As Well As Other Kitchen Utensils, Gadgets And Other Accessories As The Function Of This Edc, The Product Size Is 11.35 "X 16" And Comes In Three Different Pocket Sizes

- Good Quality Materials: Pocket Knife Display Is Handmade By Good-Quality Waxed Canvas, So The Pocket Knife Roll Is Indestructible And Can Be Used For A Long Time To Protector Your Knives From Damage And Store Hunting Knives. Butterfly Knives,Edc Pocket Knife And Other Tools Accessories

- Spacious Space For Various Knives And Tools: Our Knife Organizer Can Hold Up To 12 Knives And Accessories, Such As Paring Knives, Carving Knives, Ceramic Knives, Scissors And Other Chef Utensils Or Tools.

- Portable Design, Easy To Carry: Pocket Knife Organizer Can Be Stored In Our Product Bag And Carry The Knife Anywhere, Easy For You To Carrying It When You Go Camping, Hiking, Travelling, Fishing, Barbecue,Knife Holder Display Is Also A Great Way To Show Off Your Versatile Knife

- Worry-Purchasing Experience: When You Purchase Our Product, You Will Receive A Multifunctional Knife Storage Bag,As Well As Our 12-Month Quality Warranty And Excellent Customer Service.If You Have Any Questions, Please Explain Your Situation And We Will Solve Your Problem As Soon As Possible

- ➤ EDC Belt Organizer: The leather multitool sheath offers a better way to carry and protect your EDC tools. It has several functional area that not only for Leatherman multitools but also for car key,pen,flashlight,some Extension Kits.Everything has got its place,nothing could "just fall out". It can free your hands and spare your pocket space.

- ➤ High Quality Leather: This EDC pocket organizer is handcrafted from premium natural leather, fine and tight stitching. 100% crazy horse leather makes it to last long and comfortable.

- ➤ Dimensions: The multitool sheath size of 6.2 x 5.8 x 1 inches, equiped by belt loop fits standard belt up to 1.8 inches. With an Extra belt loop in the back there will be no bunch ups while wearing it.It fits Multitools like Leatherman Signal / Rebar / Surge / Charge / Wingman / Free P2 / Wave knife .

- ➤ Multifunction and Big Capacity:As a perfect EDC Belt Organizer to free your messy pocket,it could carry a Multitool / Flashlight / Tactical pen/ Car Key All in this one multitool sheath and with a Elastic Band for Extension Kits and a Logo band for Big knife with clip. The knife sheath is Pre-Shaped so that it's very easy to put in and out your tools.

- ➤Practical Gift Choice:The leather multitool sheath is a stylish leather craft and a practical gift choice for a men to carry on belt for daily life. The EDC Pocket Organizer could free your mess pocket and very convenient to carry your EDC stuff everyday.

- 🎁【Affordable & ideal gift】The sharpening stones for knives is the most original sharpening tool and it comes with a 1-year warranty, no matter how expensive your knife is, the knife sharpening stone will give you the sharpness you want and last without damaging your knife, an affordable set for every home, too an ideal gift for family and friends.

- 【Super Bundle】The whetstone knife sharpener includes premium 2 double-sided grit 400/1000 and 3000/8000 whetstone; angle guide holds the knife on the correct angle; Non slip bamboo base for holding the sharpening stone set; black flattening stone used for leveling; honing guide for fixing the angle of chisel and planer blades; leather strops & green polishing compound to polish knife and removing burr, with a pair of cut-resistant gloves to protect your hands.

- 【Multi-Purpose】Whetstones knife sharpening kit is suitable for the sharp needs of most family kitchen knives and tools.

- 【Safe and easy to use】Whetstone sharpening kit is equipped with a silicone non-slip bamboo base, which firmly fixes the wet stones for sharpening knives on the table, making your sharpening safer and more efficient, angle guide holds the knife on the correct angle, even a novice is easy to use.

- 【Easy to clean】The wet stone sharpening kit made of premium grade white corundum has super grinding performance. Only water is needed in the sharpening process. It can be washed with water after use. It is very easy to clean and will not affect the deliciousness of the food.

Advantages of D2 Steel

D2 steel offers several advantages that make it a popular choice among knife makers and manufacturers:

High Hardness: With a Rockwell hardness of 60-62 HRC, D2 steel is ideal for cutting tools and wear parts, providing excellent edge retention and durability.

Good Corrosion Resistance: Thanks to its high chromium content, D2 steel exhibits good corrosion resistance, making it suitable for use in harsh environments where other steels might fail.

High Wear Resistance: The high carbon content and vanadium alloying in D2 steel contribute to its impressive wear resistance, making it perfect for high-wear applications.

Good Edge Retention: D2 steel’s high hardness and wear resistance ensure that knives and cutting tools made from this steel maintain their sharp edges for longer periods, reducing the need for frequent sharpening.

Affordable: Compared to other high-end knife steels, D2 steel is relatively affordable, making it an attractive option for both knife makers and consumers looking for quality without breaking the bank.

Limitations of D2 Steel

While D2 steel has many advantages, it also comes with some limitations that need to be considered:

Brittle: D2 steel is known for its brittleness, which makes it prone to cracking. This can pose challenges during knife making and other applications where flexibility is required.

Difficult to Sharpen: Due to its high hardness, D2 steel can be challenging to sharpen. Maintaining a sharp edge requires more effort and specialized sharpening tools, which can be a drawback for some users.

Not Suitable for High-Impact Applications: The brittleness of D2 steel makes it unsuitable for high-impact applications. It tends to crack under heavy loads, limiting its use in scenarios that require high toughness.

Not Suitable for Acidic Environments: Despite its good corrosion resistance, D2 steel is not ideal for acidic environments. The high chromium content can make it prone to corrosion when exposed to acidic conditions, necessitating careful maintenance.

By understanding both the strengths and limitations of D2 steel, users can make informed decisions about its suitability for their specific needs.

D2 Steel Comparison

D2 Vs S30V

The major difference between D2 steel and S30V steel is that D2 steel is conventionally produced steel while S30V is powder metallurgy steel. S30V steel is better knife steel than D2 steel as it exhibits a more balanced approach in performance aspects like toughness, corrosion resistance, and edge retention.

A key difference to also note between D2 and CPM S30V steel is that D2 is non-stainless tool steel while S30V steel is stainless steel with excellent corrosion resistance properties.

The fine microstructure and hard vanadium carbides of S30V steel enable it to perform slightly better than D2 in edge retention. The fine microstructure also contributes to the better toughness of the S30V steel blade over the D2 blade steel.

D2 tool steel outperforms S30V steel in wear resistance due to the high amount of carbon in its composition that enables it to attain a higher Rockwell hardness than S30V stainless steel.

CPM D2 Vs D2

CPM-D2 is a powder metallurgical variant of the D2 steel. It is a relatively new steel blade in the market following advancement in steel production by Crucible CPM technology.

CPM D2 steel is more refined and has reduced chromium carbide required in die steels, thus it provides better toughness value than regular D2 steel and responds better to heat treatment.

D2 Steel Equivalent

D2 steel equivalent includes Bohler K110 steel, Cr12Mo1V steel, JIS SKD11 Steel, and 1.2379 steel. Another steel that offers close to similar performance to AISI D2 is M2 steel. For example, 1.4116 steel, commonly used in Swiss Army knives, offers similar corrosion resistance and ease of sharpening as D2 steel.

Also read CPM CruWear steel review, an upgraded version of D2 steel.

Is D2 Knife Steel Good?

The high wear resistance and edge retention make D2 steel a perfect choice for knives. You might struggle a bit with sharpening, but D2 knives are quality and affordable options.

It is suitable blade steel for a seasoned knife maker and user alike. Reputable Knifemakers like Bob Dozier have solely built their name in knife blades by utilizing D2 blade steel.

See Also: Niolox Steel Review, An improved D2 steel with added Niobium

- Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

- 【Premium Material】: Dealusy clear plastic knives heavy duty are made of food grade polystyrene, total BPA free and toxin free for your healthy meals.

- 【Extra Heavy Duty】: Each plastic knife weights 5.9g, our heavy duty plastic knives disposable with edge thickened design won’t bend easily.

- 【Heat Resistant】: These disposable knives can withstand a high temperature, ideal for hot and cold food.

- 【360 Value Pack】: This disposable knives bulk contains 360 count high quality clear plastic knives, perfect for your everyday use or serving a wedding, panic, party etc.

- 【Disposable or Resuse】: These strudy and durable knives are suitable for disposable use, or you can wash to reuse.

- Lightning-Fast Precision Meets Culinary Power: Inspired by The Scarlet Speedster, this officially licensed The Flash Edition chef knife slices with blistering speed and control. The ultra-sharp 8-12° double-bevel edge glides through prep with zero drag, delivering searing precision and friction-free performance like a Super Hero.

- Forged From Premium German Steel: Crafted from high-performance X50CRMOV15 stainless steel, trusted by chefs worldwide for its balance of sharpness, strength, and durability. With a Rockwell hardness of 54-56 HRC, this blade resists chipping and corrosion, holds its edge under heavy use, and sharpens easily for a lifetime of reliable performance.

- Titanium Nitride Coating for Zero Drag: Finished with a striking gold Titanium Nitride (TiN) coating, this blade isn’t just built to shine — it’s built to zoom. TiN reduces drag and friction for faster, smoother slicing and adds a hard, wear-resistant layer that shrugs off corrosion and everyday wear, keeping your edge sharper, slicker, and longer-lasting.

- Collector-Worthy Detail, Pro-Grade Design: DC The Flash artwork is laser-etched into the mirror-polished blade, celebrating DC’s iconic Super Hero while enhancing slicing performance by reducing food stick. A G10 handle with copper spacer ensures superior balance, comfort, and control, while full-tang construction locks in strength from heel to tip.

- Includes Premium Leather Sheath & Collector Pin: Protect your blade in storage or on the go with a genuine stamped leather sheath featuring official The Flash insignia. Every knife includes an exclusive collector’s pin and Dalstrong’s lifetime warranty plus a 70-day money-back guarantee, because your investment should be protected.

Conclusion

If you were struggling to decide on whether or not to buy a D2 steel knife, this review should give you the go-ahead. A blade from D2 is a good option compared to other non-stainless steels on the market.

D2 steel is conventionally produced and thus widely available from most tool steel companies, this makes it cheaper and easier to find as compared to powder steel. You can also find D2 as Bohler K110 Steel