If you’re in the market for a new knife, you’ve probably come across S30V steel and S35VN steel. These are two popular stainless steel options that are widely used by most knifemakers including Spyderco, CIVIVI, and Cold Steel.

However, many people have a hard time choosing between these two knife steels. It can be tough to determine which one is the best fit for your needs, especially if you’re not familiar with the nuances of different steel types.

In this article, we will compare S30V Steel and S35VN steel in terms of composition, toughness, edge retention, corrosion resistance, ease of sharpening, and price.

We’ll delve into the key characteristics and properties of S30V and S35VN steel, and help you understand the differences between the two.

By the end, you should have a better understanding of S30V and S35VN and make an informed decision on which steel is the right choice for you.

About S30V Steel

S30V steel is a popular choice for use in most types of knives. It was developed by Crucible Industries in the early 2000s and has since become a go-to steel for lots of knife makers and enthusiasts.

S30V steel is a martensitic stainless steel, made following the Crucible Particle Metallurgy Process (CPM) which produces highly homogenous steel with a balanced combination of toughness, edge retention, and corrosion resistance.

The CPM process in S30V was designed to favor the formation of vanadium carbides. Vanadium carbides are harder and have more wear resistance than chromium carbides which are often used in most stainless steels.

The result is highly efficiently balanced steel that is tough, highly resistant to wear and corrosion, making it ideal for use in most knives.

Apart from the manufacture of knives CPM S30V steel is also used in the manufacture of Pelletizing equipment, Valve components, screws, dies, and in the food and chemical industries.

About S35VN Steel

S35VN steel is a martensitic stainless steel that was developed in 2009 by Crucible Industries in collaboration with custom knife maker Chris Reeve. It is an improved version of S30V steel, designed to offer improved toughness.

S35VN steel is produced following the Crucible Particle Metallurgy (CPM) process with a focus on improved toughness, wear resistance, and resistance to edge chipping.

In CPM S35VN steel, the composition of S30V was modified by adding niobium to promote the formation of Niobium Carbides along with Chromium and Vanadium Carbides.

Apart from the manufacture of knives CPM S35VN steel is also used in the manufacture of Valve components, screws, dies, and in the food and chemical industries.

S30V vs S35VN: Comparison Table

| Specification | S30V Steel | S35VN Steel |

|---|---|---|

| Composition | Carbon 1.45% Chromium 14.00% Molybdenum 2.00% Vanadium 4.00% | Carbon 1.40% Chromium 14.00% Molybdenum 2.00% Vanadium 3.00% Niobium 0.50% |

| Rockwell Hardness | 58-61 HRC | 58-61 HRC |

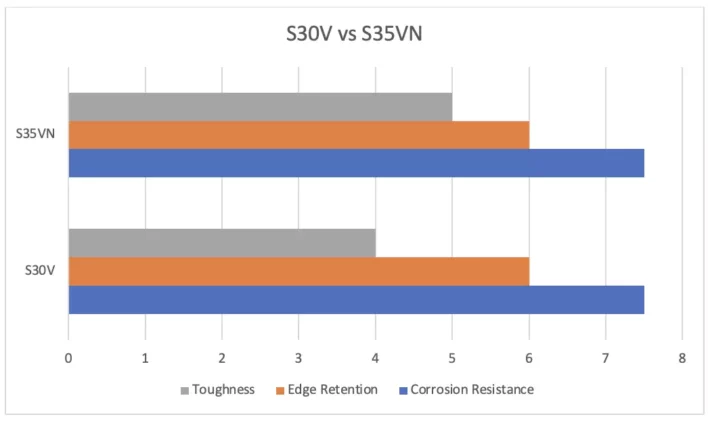

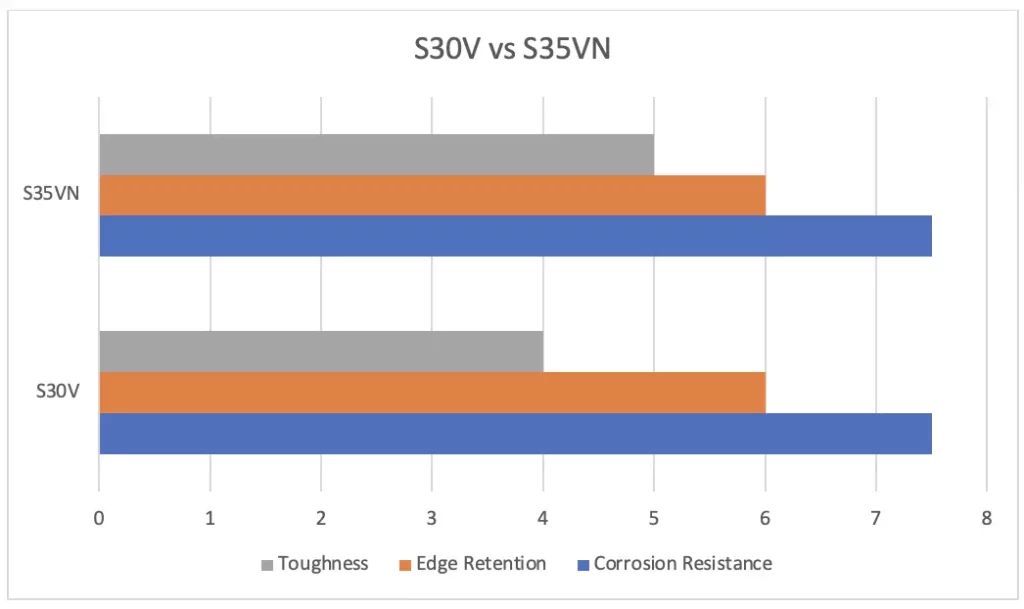

| Edge Retention | 6/10 | 5/10 |

| Toughness | 4/10 | 5/10 |

| Corrosion Resistance | 7.5/10 | 7.5/10 |

| Ease of Sharpening | Average | Averagely Easy |

Toughness

In terms of toughness, S35VN steel has a slight edge over S30V steel. In general, S35VN is about 15-20% tougher than S30V, thanks to the addition of niobium to its composition. This means that it is able to withstand more stress without breaking or chipping.

The addition of Niobium enables the formation of Niobium carbides alongside Chromium and Vanadium Carbides. The Niobium Carbides tend to substitute some of the Vanadium Carbides which are known to be hard but very brittle and potentially reduce the toughness of S30V steel.

Additionally, the increased toughness of S35VN steel improves its resistance to edge chipping and thus may increase the edge retention of S35VN over S30V.

The achieved higher transverse toughness makes CPM S35VN steel especially well-suited for use in bigger blades, such as hunting knives, tactical knives, and survival knives. This explains why you will find S35VN in most knives.

Edge Retention

S35VN and S30V are known for their excellent edge retention, which is the ability of a knife to hold a sharp edge for a long period of time even with frequent use.

In CATRA (Cutlery & Allied Trades Research Association) testing provided by Crucible Industries, S30V steel has been shown to have the same edge retention as S35VN steel.

In real-world use, S30V steel has been seen to achieve slightly better edge retention than S35VN steel.

This is likely due to the fact that S30V steel has somewhat increased Vanadium contents than S35VN steel, which can help it form much more Vanadium carbides which are known for better wear resistance and edge retention. As a result, S30V steel may be able to hold a sharper edge for a slightly longer period of time compared to S35VN steel.

It’s worth noting that the edge retention of steel can also be affected by other factors, such as the heat treatment of the steel, Rockwell Hardness and the type of edge grind applied.

The edge retention of S30V and S35VN steel is subjective to the Rockwell hardness of the knife as produced by the manufacturer. Higher Rockwell could yield better edge retention.

Both CPM S30V and CPM S35VN steel are known for their excellent edge retention, and either one would be a great choice.

Corrosion Resistance

Both S30V and S35VN steel are premium stainless steels known for their good corrosion resistance. They offer the same level of corrosion resistance despite the difference in their chemical composition.

S30V and S35VN steels both have a high chromium content of around 14%. Chromium is an important element that helps to resist corrosion. In addition to their high chromium content, both also contain other elements like molybdenum at 2%, which enhances their corrosion resistance.

For enthusiast knife makers experimenting with either of the two, note that the corrosion resistance can be negatively affected when tempered in higher temperatures.

Ease Of Sharpening

S35VN steel is easier to sharpen than S30V steel, this characteristic can be attributed to the substitution of vanadium carbides with some niobium carbides in S35VN composition.

Vanadium carbides are extremely hard and provide excellent wear resistance. However, they can also be very difficult to sharpen, as they are resistant to deformation and can be challenging to remove from the edge of a blade.

On the other hand, some studies suggest niobium carbides are slightly softer than vanadium carbides, which makes them easier to sharpen. Note that they are still able to provide good wear resistance, but are more prone to deformation, which makes them easier to remove from the edge of a blade during the sharpening process.

The substitution of some of the vanadium carbides with niobium carbides in S35VN steel allows for a balance in toughness, corrosion resistance, and ease of sharpening without a loss in wear resistance.

Intention Of Use

A key difference between S30V and S35VN steel is their toughness. S35VN steel is generally considered to be tougher than S30V steel, which makes it a better choice for larger knives.

The increased toughness of S35VN steel allows it to withstand slight heavy use and abuse more effectively without chipping and breaking, making it a great choice for hunting knives, tactical knives, and survival knives.

On the other hand, S30V steel may be more suitable for smaller pocket knives that will be subjected to less heavy use. Its slightly lower toughness means that it may not be as well-suited for heavy-use blades, as it may chip or break.

It’s important to note that your S30V or S35VN knife is not a prying tool. Using your knife as a prying tool can damage the blade edge and potentially even break it. Avoid the temptation!

Price

When it comes to the price of S30V and S35VN knives, it’s important to consider the various factors that can affect the price of steel. These factors include the availability of the steel, the demand for the steel, and the type/design of the knife.

In terms of availability, both S30V and S35VN steel are fairly widely available, although S30V steel is more common due to its age, you will find most knives in S30V steel than S35VN steel.

S30V and S35VN knives are generally considered to be similar in price, with slight variations depending on the knife design and the current market conditions.

Is S35VN Better Than S30V?

Final Thoughts On S30 vs S35VN

In conclusion, S30V and S35VN steel are both premium stainless steels that are suited for knives. Both of these steels offer a good balance in toughness, edge retention, and corrosion resistance.

S35VN steel is an improvement of S30V steel and offers improved toughness. This makes it a great choice for knives that will be subjected to slightly heavy use and need to maintain a sharper edge for an extended period of time.

Personally, I would recommend S35VN steel as it is an improvement of S30V steel and can be fetched at the same price as S30V.