Table of Contents

In this article, we will be taking a closer look at VG10 and S30V steel, two stainless steels widely used in the manufacture of most knives.

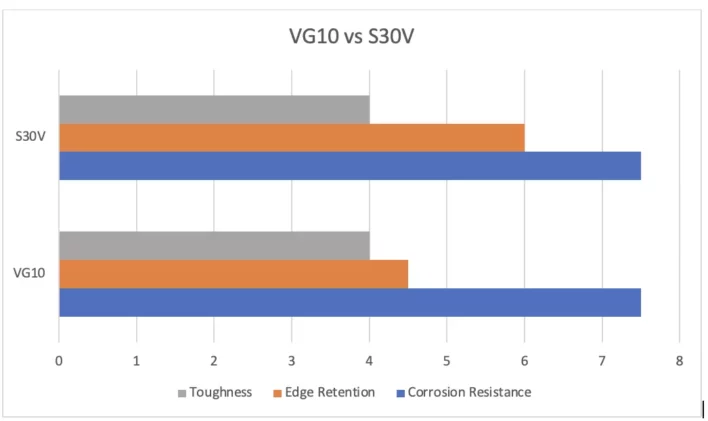

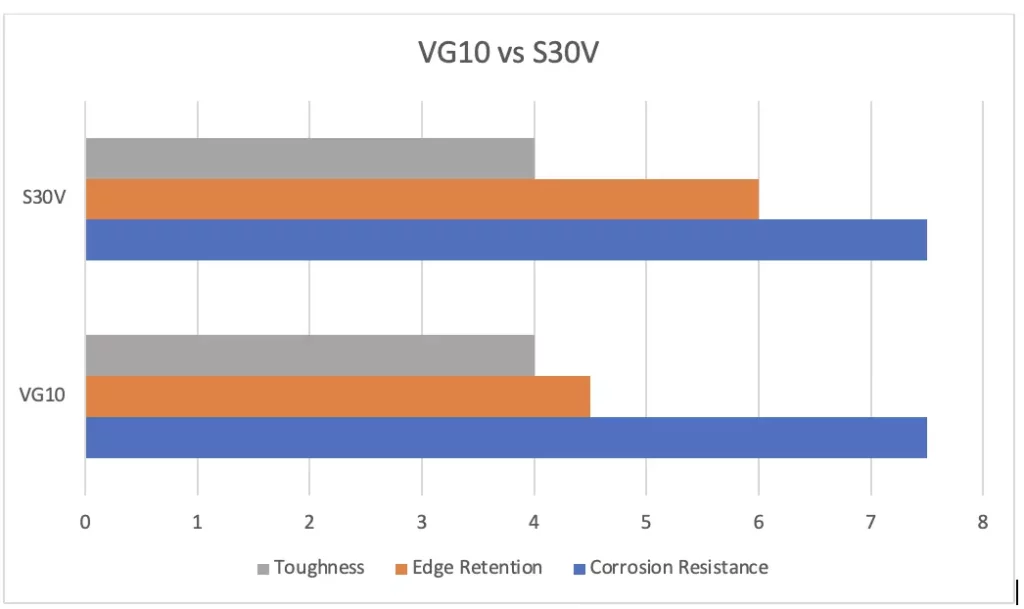

We will be comparing these two steels in terms of Toughness, Edge Retention, Corrosion Resistance, Ease of Sharpening, Intention of Use, and Price.

VG10 is a high carbon, cobalt stainless steel that is known for its corrosion and edge retention, making it suitable for use in kitchen knives and pocket knives where a sharp edge is required.

S30V is a high carbon stainless steel, but it is known for its excellent balance in edge retention, wear resistance, and corrosion resistance, making it a popular choice for use in pocket knives, outdoor and tactical knives.

Both VG10 and S30V steels are considered premium steels and are generally more expensive than other types of stainless steel.

About VG10 Steel

VG10 is a Japanese stainless steel manufactured by Takefu and is made with a high carbon content, 15% chromium (Cr), 1% Molybdenum (Mo), 0.25% Vanadium as well as the addition of 1.5% Cobalt, which gives it unique characteristics.

The cobalt addition in VG10 Steel is one of its unique features. According to research Cobalt addition is aimed at improving the steel properties when tempered at higher temperatures.

It is due to this cobalt addition that VG10 steel is able to be surface coated with coatings that require high temperature application without affecting the performance of the steel.

VG10 steel is known for its edge retention, wear resistance, and corrosion resistance making it suitable for use in folding knives and kitchen knives. It is also regarded as a premium Japanese steel and is highly sought after by most knife enthusiasts and professionals.

It is also highly resistant to corrosion due to the 15% chromium content, although it may not be as corrosion-resistant as some other types of stainless steel in the market

VG10 is commonly used in the manufacture of high-quality kitchen knives, pocket knives, and other cutting tools.

About S30V Steel

S30V steel is a martensitic stainless steel manufactured by Crucible Industries through their trademark Crucible Particle Metallurgy (CPM) process.

S30V stainless steel is a premium steel known for its excellent balance of edge retention, wear resistance, toughness, and corrosion resistance.

The CPM production process in S30V steel results in homogenous high-quality steel. S30V steel is designed in such a way that it favors the formation of Vanadium carbides alongside chromium carbides.

This is what makes S30V stainless steel unique from most other stainless steel as most stainless steel mostly contains chromium carbides, which are excellent for edge retention and wear resistance.

Apart from the manufacture of knives CPM S30V steel is also used in the manufacture of Pelletizing equipment, Valve components, screws, dies, and in the food and chemical industries.

VG10 vs S30V: Comparison Table

| Specification | VG10 Steel | S30V Steel |

|---|---|---|

| Composition | Carbon 1.00% Chromium 15.00% Molybdenum 1.00% Vanadium 0.25% Cobalt 1.55% | Carbon 1.45% Chromium 14.00% Molybdenum 2.00% Vanadium 4.00% |

| Rockwell Hardness | 58-60 HRC | 58-61 HRC |

| Edge Retention | 4.5/10 | 6/10 |

| Toughness | 4/10 | 4/10 |

| Corrosion Resistance | 7.5/10 | 7.5/10 |

| Ease of Sharpening | Easy | Average |

Toughness

Toughness in steel is the ability to resist deformation, chipping, or breaking under stress or impact.

Both VG10 Steel and S30V steel are known for their average toughness, they are not the best stainless steels for tough applications as they may be susceptible to chipping and breaking.

The average toughness in VG10 steel and S30V steel is due to the higher Rockwell hardness achieved and the presence of hard carbides in their composition.

Hard carbides although good for wear resistance and edge retention are a limiting factor when it comes to toughness as they are highly brittle.

So if you are looking for which is tougher between VG10 and S30V the answer is none, they both match each other in toughness and that cannot be a deciding factor when choosing between these two steels.

Edge Retention

Edge retention refers to a steel’s ability to maintain its sharpness over time even after repeated use. In terms of edge retention, both VG10 and S30V steel are known for their good edge retention and thus popular choice for most knives.

However, S30V steel is generally superior to VG10 steel in edge retention. S30V steel is able to achieve higher edge retention due to its finely balanced composition, containing a higher number of carbides and the CPM production process.

CPM S30V steel edge retention is particularly enhanced by the presence of Vanadium carbides which are not present in VG10 steel.

It is worth noting that there are several factors that can affect the edge retention of these steels, these include the heat treatment process, the Rockwell hardness and the type of blade grind applied.

S30V steel’s superior edge retention and wear resistance make it a favorable steel over VG10 steel in applications where there is little time to stop and sharpen the knife in use.

Corrosion Resistance

VG10 and S30V steel are both stainless steel with a high chromium content in their alloy composition. This means they can both resist rusting and corrosion better than most carbon steels and other stainless steels.

When it comes to how they compare against each other, there is no significant difference between VG10 stainless steel and S30V stainless steel in corrosion resistance.

Both steels will resist rust and corrosion in equal measure when exposed to environments with moisture and corrosive substances. It’s important to note that no type of steel is completely corrosion-proof and all blades should be properly maintained and cleaned to ensure their longevity.

The corrosion resistance of VG10 and CPM S30V steels is at par with the likes of 440C steel and SG2 steel but slightly lower than that of M390 Steel, N690 steel, and BD1N steel.

Ease of Sharpening

The ease of sharpening refers to how difficult/easy and how long it will take to sharpen a blade to a fine usable edge.

In terms of ease of sharpening, VG10 steel is generally easier to sharpen than S30V steel. This is because VG10 Steel lacks the hard Vanadium carbides contained in S30V steel.

Vanadium carbides, while good for wear resistance, edge retention, and Rockwell hardness, significantly make it hard to grind or sharpen the steel as it makes taking the material off a hard task.

Despite S30V steel being harder to sharpen than VG10 steel, it can still be sharpened by regular sharpening abrasives made of aluminum oxide only that it will take more work and time.

This property makes VG10 steel a suitable blade steel for kitchen knives that tend to require frequent sharpening when in use. VG10 stainless steel is synonymous with making high-end Japanese kitchen knives.

Intention of Use

When it comes to choosing between VG10 and S30V steel based on the intention of use, it is important to consider the characteristic where each steel excels at. Both are excellent premium steels but each may be better suited for different types of applications.

VG10 steel is known for its corrosion resistance, edge retention, and ease of sharpening, making it a good choice for use in kitchen knives and other applications where a sharp edge can be easily achieved.

It is also an excellent stainless steel thus resistant to corrosion when exposed to moisture and other corrosive environments. VG10 is commonly used in the manufacture of high-end kitchen knives, pocket knives, and other cutting tools.

The addition of Cobalt in VG10 composition also makes it a good choice for blades that may need a surface coating that is normally applied at high temperatures.

S30V Stainless steel is known for its excellent balance in edge retention, toughness, and corrosion resistance, making it a popular choice for use in EDC knives and high-end kitchen knives.

It is fairly tough and is able to withstand slight heavy use and thus may sometimes be used to make outdoor knives. S30V is often used in the manufacture of high-end knives where its edge retention, wear resistance, and corrosion resistance are of necessity.

Price

S30V steel is generally pricier than VG10 steel. This is due to a number of reasons, firstly S30V steel is powder steel which is expensive to produce compared to conventional steel. Secondly, S30V steel offers better wear resistance and edge retention than VG10 steel.

Thirdly, S30V steel offers a more balanced approach towards all the properties thus toughness, edge retention, corrosion resistance, and ease of sharpening. It is thus considered a better package than VG10 steel.

Is VG10 better than S30V?

VG10 is considered to be easier to sharpen than S30V, but S30V is better in terms of edge retention and wear resistance. Both VG10 and S30V steels have equal toughness and corrosion resistance, and they are considered to be among the top choices for high-end knives.

What steel is better than VG10?

Several steels are better than VG10 steel, MagnaCut steel in particular is better than VG10 steel in Toughness, Edge retention, and corrosion resistance. SG2 steel is also another steel considered to be a better version of VG10 steel as it is a powder metallurgy version of VG10 stainless steel that achieves better edge retention.

Conclusion

In conclusion, S30V steel is a powder metallurgy steel with better alloy composition and better performance than VG 10 Steel in edge retention and wear resistance.

S30V has higher carbon content at 1.45% compared to the VG 10 steel’s 1.05%. This carbon content gives it higher Rockwell hardness and wear resistance while enhancing its edge retention properties over VG 10 Steel

The Crucible Particle Metallurgy production process results in a finer microstructure with uniform distribution of carbides, which greatly improves S30V knife steel properties over those of conventionally produced steel like VG 10 steel.

S30V steel blade is most comparable to a VG-10 steel blade in terms of corrosion resistance. They offer the same level of corrosion resistance, and for this reason, you will find most pocket knives and Everyday Carry (EDCs) made of VG 10 steel and S30V steel.