CPM 3V steel is a high carbon tool steel produced by crucible industries following the Crucible Powder Metallurgy technology.

It is commendable for its extreme toughness and wear resistance, and it is categorized in the same class as other tool steels belonging to the Crucible Killer-V’s that include CPM 3V, CPM 9V, CPM 10V, CPM 15V, as well as CPM M4

Its properties make it suitable for the manufacture of dies, stamping tools, scrap choppers, knives, shearing blades, and punches, to mention a few.

In the knife industry, it is used to make swords, large blades, and fixed blade knives because of their excellent ability to resist chipping and breaking when subjected to tough tasks.

Note that CPM 3V is not stainless steel because it does not have enough chromium to make it stainless steel.

CPM 3V steel composition

- Carbon C 0.80%: Increases the edge retention, hardness and tensile strength. It also improves steel resistance to wear, abrasion and corrosion.

- Chromium Cr 7.50%: Formation of Chromium carbide Increases hardness, tensile strength and corrosion resistance of the blade.

- Molybdenum Mo 1.30%: It improves machinability and hardness.

- Vanadium V 3.00%: Increase wear resistance and toughness, it also improves corrosion resistance.

- Tungsten W 0.40% Improves wear resistance and hardness, mostly added to tool steel.

- Manganese Mn 0.40%: Increases Hardness and brittleness.

- Silicon Si 0.90%: Increases strength and heat resistance.

- Phosphorous P 0.03%: Improves steel strength and resistance to corrosion but is generally consider detrimental when added in plenty.

- Sulfur S 0.03%: Sulphur improves machinability but is normally regarded as an impurity it is thus added in low quantities.

- SK5 Steel Durability: Made from industrial-grade SK5 high carbon steel, these heavy duty utility blades provide exceptional hardness and edge retention. Compared to standard carbon steel, SK5 offers improved wear resistance and extended life span, ensuring fewer blade changes and higher efficiency during cutting tasks. Whether you're working on renovation projects, packaging, or construction sites, these blades can handle tough materials like carpet, drywall, rubber, and rope with ease

- Standard Size Fit: This utility knife blades 100 pack is crafted to meet universal blade specifications, ensuring a perfect fit with most retractable utility knives, folding knives, and box cutters. Whether you're replacing utility knife blades for everyday tasks or switching out box cutter blades on the job, these standard-size blades deliver reliable compatibility and performance you can count on across various tools and scenarios

- Razor Sharp Edge: Our razor blades for utility knife are precision-honed to deliver ultra-sharp, clean cuts every time. Engineered with a refined edge angle, these blades slice effortlessly through thick cardboard, leather, carpet, vinyl, linoleum, soft metals, and more. The sharpness reduces drag, improves control, and minimizes hand fatigue—making it the ideal choice for DIYers, contractors, or warehouse professionals

- Safe Storage Box: Each set comes with a compact and durable utility blade storage box that protects blades from dust, moisture, and accidental contact. The slide-out design allows safe, one-at-a-time access to blades while keeping unused blades neatly organized. Whether stored in a toolbox, desk drawer, or tool belt, this box keeps your workspace safer and your workflow smoother

- Trusted by Pros & DIYers: These replacement blades for utility knife are built with Jetmore’s commitment to precision and durability. Whether you're a professional in construction, a warehouse operator, a DIY hobbyist, or simply handling everyday home repairs, Jetmore delivers blades you can trust. We stand behind our quality—so you can cut with confidence, knowing your tools won’t let you down

- Notice: Be sure to watch our HOW-TO video before using it. It can help you slide the utility blade out quickly and easily

- Super Versatility: It is made entirely according to standard utility knife blades and fits most standard & fixed utility knives perfectly

- Affordable: Includes 100-pack replacement blades and they come in a well-built case for safe storage and disposal. Each blade is rigorously tested and we firmly believe this is a great deal

- Durability: WORKPRO utility knife blades are made from SK5 steel, which is of high quality and durability

- Sharp: The knife blades are highly sharp and cut through lots of materials easily and without hesitation. Ideal for cutting cardboard, leather, linoleum, rope, soft metal, etc

- Heavy duty utility blade for general cutting, trimming, and scraping of a variety of materials

- Precision-honed edge for consistent and long cutting life

- Fits most standard utility knives

- 100 pack

CPM 3V steel properties

CPM 3V Steel Hardness

CPM 3V steel hardness ranges from 58 to 60 HRC as per the Rockwell hardness scale. This hardness range is considered perfect for knife steels.

However, the steel can attain a higher hardness of up to 64 HRC depending on the heat treatment.

Note that toughness reduces with such high hardness. Most steels will offer you high hardness at the expense of toughness but not the case with CPM 3V steel.

CPM 3V Steel Toughness

The ability to withstand breakage and chipping during use is essential when determining if steel is suitable for knife making.

CPM 3V offers excellent toughness, and you can be sure that knives made from this steel will not break as a result of impacts from tough applications like batoning or chopping.

CPM 3V Steel Wear resistance

Another area of excellence of this steel is its wear resistance which is first associated with the CPM production technology.

Also, CPM 3V is high in carbon and vanadium, which leads to the formation of hard vanadium carbides, which boosts its wear resistance capabilities.

If you are searching for a knife that will serve you across generations despite the applications, look into options of CPM 3V knives.

CPM 3V Steel Edge retention

Hardness influences the edge retention of steel; the higher the hardness, the better edge retention capabilities.

With this steel offering high hardness, its edge retention features are commendable. It remains sharp longer than other tool steels out there, but it is not as good as premium steels.

CPM 3V Steel Corrosion resistance

So is CPM 3V steel stainless? CPM 3V is not stainless steel, but the chromium elements in its composition give it good corrosion resistance properties. Since this steel is not optimized for corrosion resistance, proper care is vital to keep it from rusting. Proper care involves cleaning and drying it after use.

To improve the corrosion resistance, manufacturers apply tough anti-corrosion coatings. CPM 3V corrosion resistance is at par with that of CPM CruWear steel.

Ease of Sharpening CPM 3V Steel

Being hard steel, sharpening CPM 3V steel will take some time and effort. To ease the struggle, users are advised to use harder abrasives.

Getting a sharp edge with this steel will be a daunting task if you do not have the right sharpening skills and tools.

The good news is blades made with this steel hold an edge for a long. Therefore, you will not be required to go through the hustle of sharpening now and then.

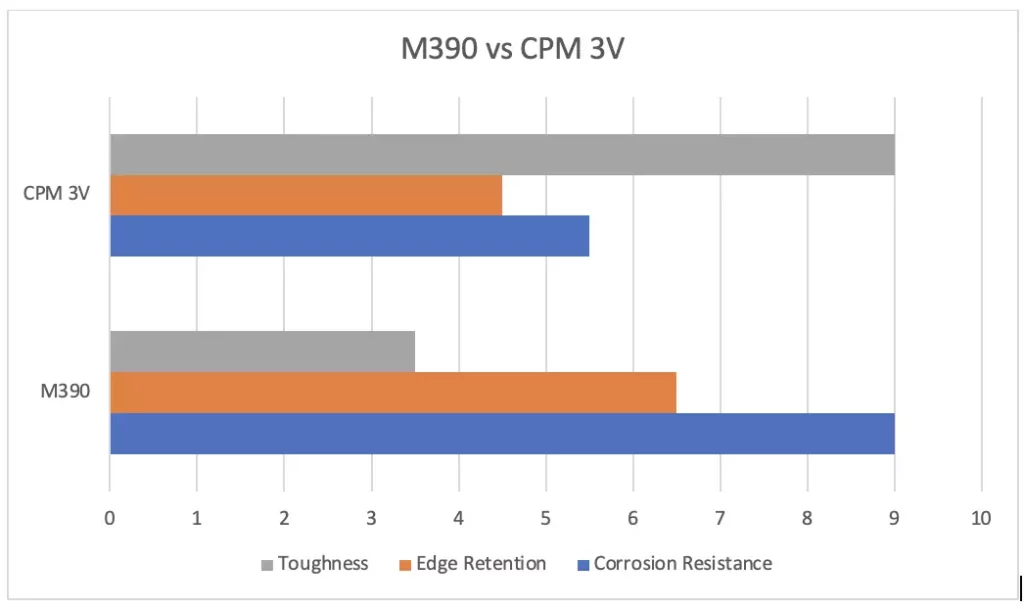

CPM 3V Steel comparison

CPM 3V steel vs S35VN

Both 3v steel and S35VN steel offer almost the same edge retention. But S35VN steel offers better edge retention, corrosion resistance, and it is easier to sharpen than 3V. On the other hand, 3V shines in toughness. When it comes to price, CPM 3V is cheaper than S35VN.

CPM 3V vs CPM 10V Steel

Both 3V and 10V steel belong to the crucible family of high vanadium steel. CPM 10V steel is harder than 3V. It offers excellent wear resistance and edge retention over 3V. One unique feature of 10V over 3V is its incredible toughness even at the high hardness of about 64HRC.

CPM 3V steel vs CPM M4

Both 3V steel and M4 steel are produced following the CPM technology but differ in properties. 3V steel tops in toughness, corrosion resistance, and it is easier to sharpen, while M4 steel offers better edge retention.

CPM 3V steel vs D2 Steel

Both 3V steel and D2 steel are tool steels, they there have almost similar performance. However, CPM 3V can be considered the better of the two as it offers better Toughness, better edge retention, and Matches D2 Steel in corrosion resistance.

CPM 3V steel vs S30V

CPM 3V steel offers better Edge retention and toughness over S30V steel. On the hand S30V steel beats CPM 3V steel in corrosion resistance as it is stainless steel. They both perform similarly on ease of sharpening.

- Multipurpose Knife Set: This kitchen knives set includes 8" Chef Knife, 8" Slicing Knife, 7" Santoku Knife, 8" Serrated Bread Knife, 5" Utility Knife, 3.5" Paring Knife, Kitchen Shears and 6 pcs Blade Guards

- Anti-rust coating: The healthy anti-rust coating protects the knife from oxidation and dishwasher safe, while the non-stick coating ensures the blades stay clean all day long

- Easy to carry: Each knife comes with a blade guard for safe, compact storage in your kitchen cupboard. These knives are also easy to carry when camping or storing in your RV

- Perfect Holiday Gift: Ideal for kitchen enthusiasts or new cooks, this knife set meets all cooking needs. It makes an excellent holiday gift for family, friends, lover and colleague

- Lifetime Warranty: Every knife set is backed by rigorous quality inspection, we provide a lifetime warranty for every customer, ensuring superior customer service and peace of mind with every purchase

- 【Premium Material】: Dealusy clear plastic knives heavy duty are made of food grade polystyrene, total BPA free and toxin free for your healthy meals.

- 【Extra Heavy Duty】: Each plastic knife weights 5.9g, our heavy duty plastic knives disposable with edge thickened design won’t bend easily.

- 【Heat Resistant】: These disposable knives can withstand a high temperature, ideal for hot and cold food.

- 【360 Value Pack】: This disposable knives bulk contains 360 count high quality clear plastic knives, perfect for your everyday use or serving a wedding, panic, party etc.

- 【Disposable or Resuse】: These strudy and durable knives are suitable for disposable use, or you can wash to reuse.

- Lightning-Fast Precision Meets Culinary Power: Inspired by The Scarlet Speedster, this officially licensed The Flash Edition chef knife slices with blistering speed and control. The ultra-sharp 8-12° double-bevel edge glides through prep with zero drag, delivering searing precision and friction-free performance like a Super Hero.

- Forged From Premium German Steel: Crafted from high-performance X50CRMOV15 stainless steel, trusted by chefs worldwide for its balance of sharpness, strength, and durability. With a Rockwell hardness of 54-56 HRC, this blade resists chipping and corrosion, holds its edge under heavy use, and sharpens easily for a lifetime of reliable performance.

- Titanium Nitride Coating for Zero Drag: Finished with a striking gold Titanium Nitride (TiN) coating, this blade isn’t just built to shine — it’s built to zoom. TiN reduces drag and friction for faster, smoother slicing and adds a hard, wear-resistant layer that shrugs off corrosion and everyday wear, keeping your edge sharper, slicker, and longer-lasting.

- Collector-Worthy Detail, Pro-Grade Design: DC The Flash artwork is laser-etched into the mirror-polished blade, celebrating DC’s iconic Super Hero while enhancing slicing performance by reducing food stick. A G10 handle with copper spacer ensures superior balance, comfort, and control, while full-tang construction locks in strength from heel to tip.

- Includes Premium Leather Sheath & Collector Pin: Protect your blade in storage or on the go with a genuine stamped leather sheath featuring official The Flash insignia. Every knife includes an exclusive collector’s pin and Dalstrong’s lifetime warranty plus a 70-day money-back guarantee, because your investment should be protected.

Is CPM 3V the perfect knife steel?

CPM 3V has all the properties that make good knife steel, including excellent toughness, great edge retention, and good wear resistance.

Its major downside is poor corrosion resistance, which is easily handled by anticorrosive coating and proper care.