A2 steel is air-hardening steel produced by crucible industries. The A in the name is the designation for air hardening.

Knifemakers love this tool steel because it is easy to work with and has high toughness and moderate wear resistance. These features make it an ideal choice for making survival, combat, camping, and hunting knives.

What’s more, AISI A2 tool steel is not stainless steel because it does not contain enough Chromium to make it stainless steel. This tells you that it performs poorly in corrosion resistance.

A2 steel composition

- Carbon C 1.05%: Increases the edge retention, hardness and tensile strength. It also improves steel resistance to wear, abrasion and corrosion.

- Chromium Cr 5.50%: Chromium Increases hardness, tensile strength and toughness of the blade.

- Molybdenum Mo 1.40%: It improves machinability and gives A2 steel the characteristic air hardening property.

- Vanadium V 0.25%: Increase wear resistance and toughness, it also improves corrosion resistance. Vanadium acts by improving the grain structure and the carbide structure of the steel.

- Manganese Mn 1.00%: Increases Hardness and brittleness.

- Nickel Ni 0.30% enhances structure properties of the steel

- Silicon Si 0.50%: Increases strength and heat resistance.

- Phosphorus P 0.03%: Improves machinability and hardness.

- Sulfur S 0.03%: Improves machinability.

- Copper Cu 0.25% Slightly increases corrosion resistance in the alloy of the steel.

A2 steel properties

A2 steel Hardness

A2 steel hardness is 57-62 HRC as per the Rockwell hardness scale. However, the hardness varies with the heat treatment temperature technique used by the manufacturer.

This high hardness is made possible by the combination of Chromium, Manganese, and Molybdenum in its composition.

A2 Toughness

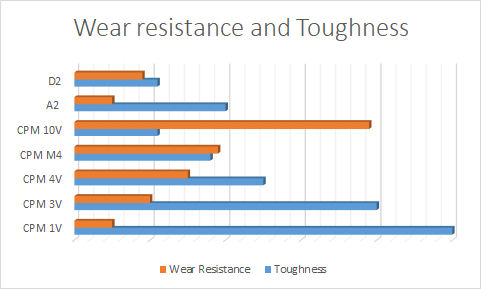

You would expect low toughness in A2 tool steel because it is hard steel, but surprisingly it offers great toughness. It is because of this toughness that AISI A2 steel has remained a go-to choice for die steel over the years.

If you are on the market for knives that won’t break, chip, or crack on tough applications, consider the varieties of A2 steel.

The high toughness in this steel is associated with vanadium and nickel in its composition, and for that, it will continue to be a good choice for knives intended for tough use.

A2 Wear resistance

The toughness level of A2 steel can be defined as okay or moderate. In many cases, hard steels offer excellent wear resistance but for this steel, you will enjoy high toughness at the expense of wear resistance. Well, this is not to say that it offers the worst wear resistance out there, but expect to meet other types of steel with better wear resistance.

A2 steel Corrosion resistance

As already stated, A2 is not stainless steel because of its low chromium contents. With that it offers low corrosion resistance, however, it is better in corrosion resistance than some carbon steels.

If the other properties of A2 tool steel match the kind of knife you are looking for, do not forgo A2 steel knives because of their low antirust capabilities because you can protect them from rusting through proper care.

Ensure to clean and dry them after use and also apply a coat of oil which acts as a protective layer from rust agents during storage.

A2 Edge retention

Another area where this steel shines is in its edge retention capabilities associated with high chromium carbides in its composition.

Do not expect A2 steel knives to keep an edge like high-end steels, but you can be sure that you will not be required to sharpen them often.

Sharpening A2 steel

After confirming that A2 steel does not become dull faster, you must be wondering if it is easy to sharpen. The good news is, it is easy to sharpen A2 steel, which is due to its low wear resistance caused by the relatively low volume of chromium carbide.

It will take you a short time and effort to get a super sharp edge that lasts you long with this steel.

- HIGH-QUALITY MATERIALS: This Damascus one-handed knife features a VG10 steel core blade, combining the elegant patterns of Damascus steel with outstanding strength and durability, ensuring precise cutting and long-lasting performance.

- PORTABLE & CONVENIENT DESIGN: It comes equipped with a sturdy pocket clip, offering convenient portability for outdoor activities or everyday use.

- ELEGANT & DURABLE HANDLE: The beautifully designed handle not only provides a comfortable grip but also adds a touch of natural elegance, enhancing both aesthetics and functionality.

- IDEAL GIFT FOR KNIFE LOVERS: A truly unique piece, this knife makes a fantastic gift for collectors, outdoor enthusiasts, or anyone who values high-quality tools and craftsmanship.

- NATURALLY ELEGANT HANDLE: The handle is designed for a comfortable grip and showcases a natural beauty that complements the knife's durability and performance.

- CIVIVI MINI PRAXIS --- Constructed from black stonewashed D2 steel that perfectly blends edge retention, corrosion resistance, and ease of sharpening. This folding knife with the handy pocket clip is the ideal option for everyday carry that is legal in all states and will stay strong through all of your adventures.

- COMFORT GRIP --- We use G10 handle that is smooth to the touch, extremely durable and resistant to moisture and temperature changes. The comfortable handle provides a substantial grip while still being light and maneuverable in hand.

- EXCELLENT DETENT --- In order to ensure smooth and fast operation, we've outfitted the mini praxis with a ceramic ball-bearing pivot construction which allows for quick and snappy one-handed flipper deployment and smooth closing action. A strong detent ensures that this knife will maintain crisp, snappy action for a lifetime of use.

- PERFECT KNIFE FOR EDC --- urban knife, work knife. Box, letter, envelope opening knife. Compact knife to be carried in a purse, backpack, pocket. Good for indoor and outdoor use. Small pocket knife. Hiking, camping knife. Best gifts for men and women.

- USA SERVICE CENTER --- CIVIVI knives and tools provide a lifetime service against defects in material and workmanship, USA service center provides faster response to take care of your requests.

- Dimensions - Overall Length: 8.5"(216mm); Blade Length: 3-5/8"(92mm); Blade Thickness: 5/32" (4mm); Weight: 6.48 oz(184g)

- Full-Tang Construction - Full tang design has more excellent sturdiness and durability than the average half tang knife. Ergonomic G10 handle provides comfortable and secure grip, curved design to save effort

- High-Quality - Blade is made of premium D2 steel for excellent hardness. Excellent heat-treated fixed blade with ultra-sharp edge, hardness up to 60-62HRC. Stonewashed surface add tough and corrosion resistance to the blade surface

- Easy to Carry - Durable nylon protective sheath can store the knife in place. Belt clip can help hang on the belt or backpack safely and securely, easy to carry

- Wide Application - Flissa full tang fixed blade knife is suitable for hunting, camping, hiking, survival, outdoor activities and home daily use

A2 steel equivalents

A2 vs O1

A2 steel beats AISI O1 tool steel in wear resistance, corrosion resistance, and easy sharpening, while O1 tool steel shines in edge retention. One major difference is during heat treatment A2 steel is quenched in air while O1 steel is quenched in oil.

A2 vs D2

A2 offers better edge retention, and toughness and it is easier to sharpen than D2 tool steel . However, AISI D2 offers better corrosion resistance than A2 because it is semi-stainless steel.

A2 vs 1095

1095 steel is easier to sharpen than A2 tool steel but loses the battle in terms of edge resistance, toughness, and corrosion resistance. An A2 blade beats a 1095 steel in multiple aspects making the better choice.

Is A2 steel good knife steel?

Some of the properties that make steel good for knives are great hardness, toughness, edge retention, and good wear resistance. Looking at the features of A2 steels, it performs great on all the above, therefore we can say that it is a good steel for knife blade.

The only downside is its low rust resistance, which can be handled through proper care and maintenance.

Conclusion

A2 steel is a medium carbon steel that is relatively inexpensive and offers great edge retention and wear resistance. It is a common steel in knife making and can make quality and cheap hunting, bushcraft, and camping knives.

The only let off is that A2 steel is not stainless steel and it is prone to rusting due to lack of enough chromium elements.