What is CPM 4V Steel?

The combination of its chemicals gives this steel high toughness and outstanding wear resistance. Therefore, it is suitable for manufacturing tools and knives to be used in applications that require a combination of wear resistance, strength, and toughness.

CPM 4V steel Chemical composition

- Carbon C 1.35%: Increases the edge retention, hardness and tensile strength. It also improves steel resistance to wear, abrasion and corrosion.

- Chromium Cr 5.00%: Formation of Chromium carbide Increases hardness, tensile strength and corrosion resistance of the blade.

- Molybdenum Mo 2.95%: It improves machinability and hardness.

- Vanadium V 3.85%: inhibits grain growth during elevated temperature processing and heat treatment, which enhances strength and toughness of steel. It also forms carbides that increase wear resistance.

- Tungsten W 0.40% Improves wear resistance and hardness, mostly added to tool steel.

- Manganese Mn 0.40%: improves the strength and hardness of steel. When the steel is heat treated, hardenability is improved with increased manganese.

- Silicon Si 0.80%: Increases strength and heat resistance.

Properties of CPM 4V steel

CPM 4V steel Hardness

CPM 4V hardness is 64HRC which is very impressive. With this hardness level, knives made from this steel portray high wear resistance, excellent edge retention, and, most importantly, without compromising toughness.

CPM 4V steel Wear resistance

Like any other hard steel, CPM 4V offers excellent wear resistance. This means that 4V knives stay in good shape for long, irrespective of the abrasive and adhesive situations you put them through.

Although CPM 4V will wear out eventually because of sharpening and other applications that put them through wear and tear, they will have served you long enough, possibly across generations.

The excellent wear resistance is associated with carbon, vanadium, and molybdenum in its composition.

CPM 4V steel Toughness

In the world of steel, you can either get hardness or toughness from steel but not both. Considering the hardness of 4V, we can conclude that it is brittle steel. However, this is not the case. CPM 4V offers high hardness while maintaining good toughness. 4V knives do not break or chip easily when used for challenging applications.

CPM 4V Steel Edge retention

Edge retention is the measure of how long steel retains sharpness with frequent use, and it is determined by the wear resistance of steel. CPM 4V offers excellent wear resistance hence holds an edge for long. Knives made from this steel do not require frequent sharpening.

If you have been searching for a knife that will not require you to sharpen in the middle of cutting, the varieties of 4V will never disappoint you.

CPM 4V steel Corrosion resistance

CPM 4V is not stainless steel because the Chromium in its composition does not make it stainless steel. The 5% chromium offers some level of corrosion, but it does not make this steel completely rust-free.

Proper care, which entails cleaning and drying knives is crucial to protect them from rusting.

If you are out to purchase knives to be used in humid situations or in areas with salty water, stay away from the varieties of 4V knives.

Sharpening CPM 4V steel

Being hard steel, CPM 4V is not easy to sharpen. Getting a sharp edge will require a lot of your energy and time. However, you can make the process easy by using sophisticated sharpening tools. Always ensure that the abrasive tool you are using is harder than 4V.

The good news is, this steel holds an edge for long, and so once you attain a sharp edge, you will stay for a long time without the need to go through the challenging sharpening.

CPM 4V steel comparison with other knife steels

CPM 4V vs. CPM 3V

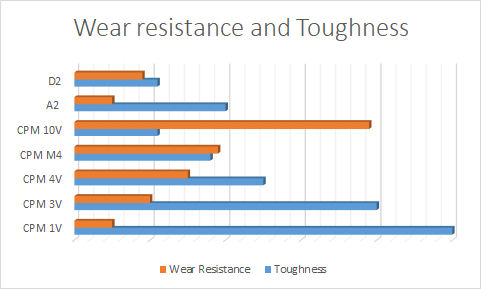

Crucible industries produce both steels, and 4V is an upgrade of 3V steel. They offer the same level of corrosion resistance and ease of sharpness. They however differ in two aspects CPM 3V offers higher toughness, while CPM 4V offers better edge retention.

CPM 4V vs. LC200N

CPM 4V beats LC200N steel by a big margin in edge retention and toughness while LC200N steel shines in corrosion resistance and ease of sharpness. LC200N steel will be better suited for humid and salty water environments that will increase rusting of the blade.

CPM 4V vs CPM 10V

CPM 4V and 10V are all made by crucible following the same production process, the only difference is the composition of the alloys. CPM 10V offers higher toughness and is more suitable for knives that their applications require additional wear resistance. 10V offers almost three times the wear resistance of 4V. 4V is much easier to sharpen than 10V due to the low wear resistance.

See Also: CPM MagnaCut Steel, an equivalent to 4V with better Corrosion Resistance.